Concept and application of DTH drilling rig

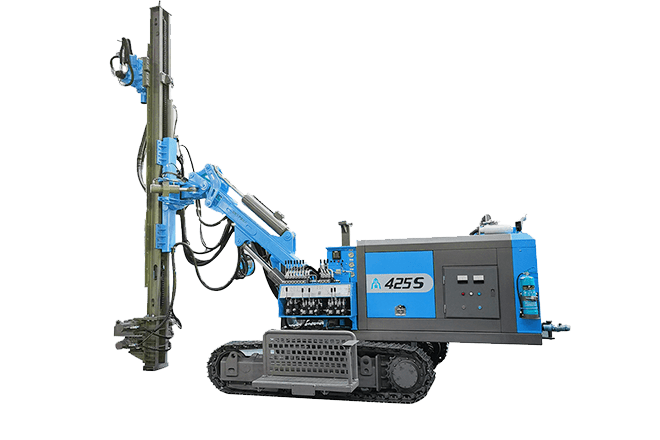

.png) The drilling tool consists of drill pipe, ball tooth drill bit and impactor. When drilling, use two drill pipes to drill. The reverse air supply mechanism consists of a reverse motor, a reverse reducer, and an air supply inverter. The counter-rotating reducer is a three-stage cylindrical gear closed anisotropic component, which is automatically lubricated by a spiral oiler. The air supply inverter is composed of a connecting body, a seal, a hollow spindle and a drill pipe joint part. It is equipped with a pneumatic grab for receiving and unloading the drill pipe. The lifting pressure regulating mechanism is composed of a lifting motor with the help of a lifting reducer and a lifting chain, so that the reversing mechanism and the drilling tool complete the lifting action.

The drilling tool consists of drill pipe, ball tooth drill bit and impactor. When drilling, use two drill pipes to drill. The reverse air supply mechanism consists of a reverse motor, a reverse reducer, and an air supply inverter. The counter-rotating reducer is a three-stage cylindrical gear closed anisotropic component, which is automatically lubricated by a spiral oiler. The air supply inverter is composed of a connecting body, a seal, a hollow spindle and a drill pipe joint part. It is equipped with a pneumatic grab for receiving and unloading the drill pipe. The lifting pressure regulating mechanism is composed of a lifting motor with the help of a lifting reducer and a lifting chain, so that the reversing mechanism and the drilling tool complete the lifting action.In the closed chain system, a pressure regulating cylinder and a moving pulley block are installed. During normal operation, the piston rod of the pressure regulating cylinder pushes the pulley block to complete the decompression drilling of the drilling tool.

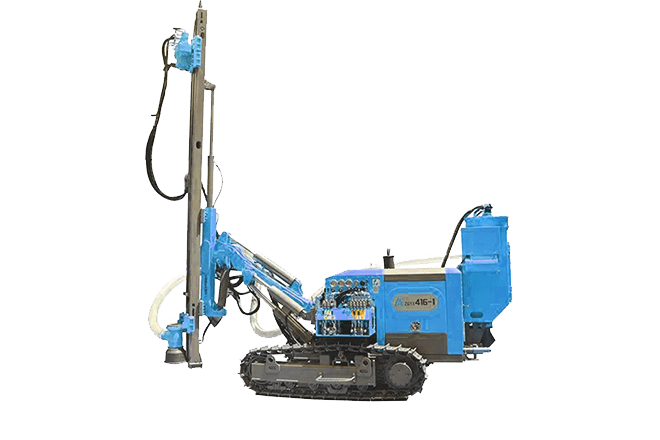

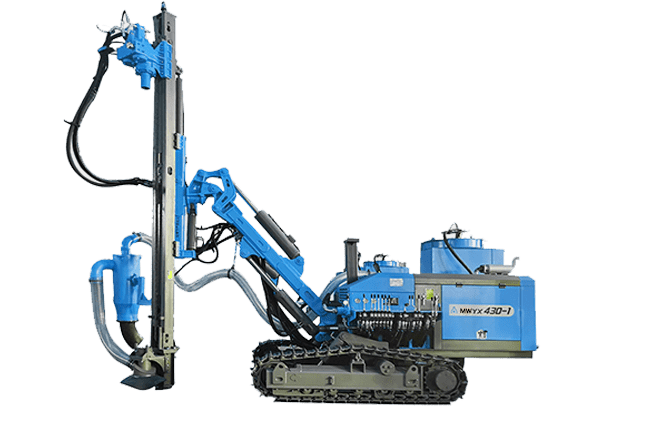

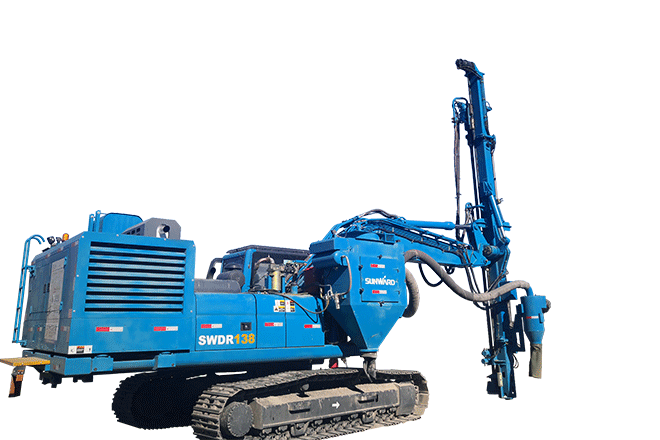

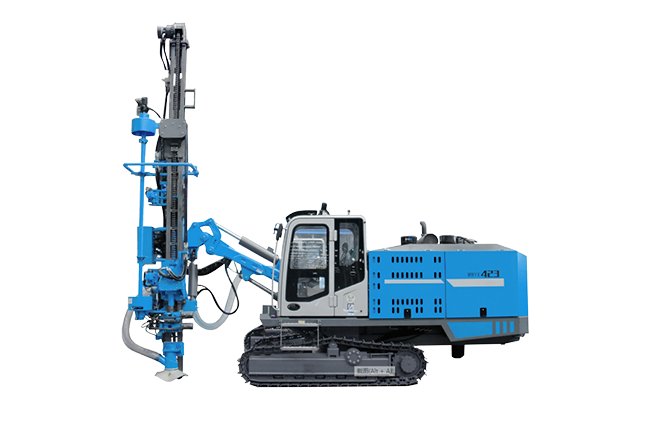

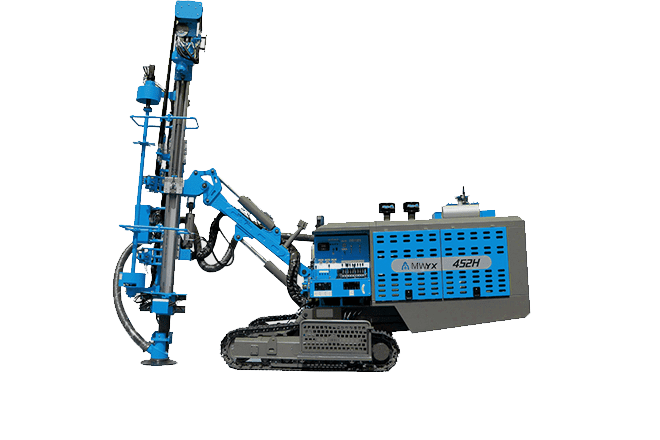

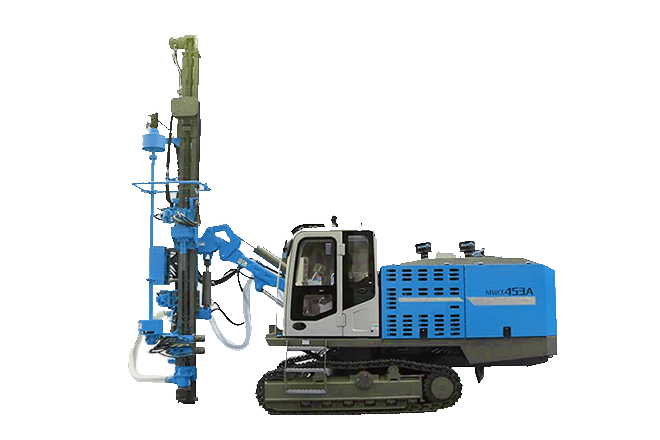

The down-the-hole drilling rig consists of a rotary mechanism, a lifting mechanism, a pushing mechanism, a supporting mechanism and an impact mechanism.

Classification of down-the-hole drilling rigs

Classification of down-the-hole drilling rigsThe structures of down-the-hole drilling rigs are divided into two types: integral type and split type. According to the exhaust mode, it is divided into two types: side exhaust and center exhaust. According to the shape of the carbide embedded in the working surface of the down-the-hole drilling rig, there are blade-type down-the-hole drilling rigs, column-tooth down-the-hole drilling rigs and blade-type hybrid drills. type down-the-hole drilling rig.

The integral down-the-hole drilling rig is a single down-the-hole drilling rig whose head and tail are integrated into one. It is easy to process and easy to use, and can reduce the loss during energy transfer. The disadvantage is that when the working surface of the down-the-hole drilling rig is damaged, it will be scrapped as a whole. The head of the split down-the-hole drilling rig and the tail (drill tail) of the down-the-hole drilling rig are separated, and special threads are used to connect the two. When the head of the down-the-hole drilling rig is damaged, the drill tail can still be used, saving steel. However, the structure is more complex and the energy transfer efficiency is reduced.

(2).jpg) Working principle of down-the-hole drilling rig

Working principle of down-the-hole drilling rig

The working principle of the down-the-hole drilling rig is the same as that of the ordinary impact rotary pneumatic rock drill. The pneumatic rock drill combines the impact and rotary mechanism, and the impact energy is transmitted to the drill bit through the drill pipe; while the down-the-hole drilling rig separates the impact mechanism (impactor) and dives into the bottom of the hole. No matter how deep the drilling is, the drill bit is directly installed on the On the impactor, there is no need to transmit impact energy through the drill pipe, thus reducing the loss of impact energy.As the drilling depth of a down-the-hole drilling rig increases, the loss of rock drilling capacity increases at the submersible rods, joints (medium and deep hole drilling), etc., the drilling speed decreases significantly, and the cost increases. In order to reduce the loss of capacity and improve drilling efficiency, a down-the-hole drilling rig was designed in actual projects. Down-the-hole drilling rigs also use compressed air as power to rotate, impact and break rocks to form holes. Its working principle is that the pneumatic impactor of the down-the-hole drill and the drill bit are installed on the front end of the drill rod. When drilling, the propulsion mechanism continuously advances the drilling tool and applies a certain axial pressure to the bottom of the hole, so that the drill bit and the bottom of the hole The rocks are in contact with each other; the rotary mechanism makes the drilling tool continuously rotate, and the impactor installed in front of the drill pipe, under the action of compressed air, makes the piston impact the drill bit back and forth to complete the impact on the rock; the compressed air enters from the rotary air supply mechanism. The hollow rod reaches directly to the bottom of the hole and discharges the broken rock powder from the annular space between the drill pipe and the hole wall to the outside of the hole. It can be seen that the essence of down-the-hole rock drilling is the combination of impact and rotation methods to break rocks under the action of axial pressure. The impact is intermittent and the rotation is continuous. The rock is broken under the impact and shear force. Being constantly crushed and sheared under the influence. In down-the-hole rock drilling, impact work plays a leading role.

.jpg)

.jpg)

.jpg)

-

DTH Drill Tools Product Customization: Meeting Unique Mining Needs

DTH Drill Tools Product Customization: Meeting Unique Mining Needs -

ZGYX 454H down-the-hole drill & ZGYX 454G photovoltaic drill, all-round solutions for hard rock and photovoltaic scenarios

ZGYX 454H down-the-hole drill & ZGYX 454G photovoltaic drill, all-round solutions for hard rock and photovoltaic scenarios -

.jpeg) What is a drilling rig

What is a drilling rig -

D Miningwell x LIUTECH: A Deep Engagement Journey of Corporate Exchange in the Air Compressor Industry

D Miningwell x LIUTECH: A Deep Engagement Journey of Corporate Exchange in the Air Compressor Industry

.png)