ZGYX 454H down-the-hole drill & ZGYX 454G photovoltaic drill, all-round solutions for hard rock and photovoltaic scenarios

Jun 18, 2025

Today, we will introduce the ZGYX454H integrated open-pit down-the-hole drill and the ZGYX454G integrated open-pit photovoltaic drill. The high-strength body structure design can meet the use requirements of harsh working conditions. The product has high construction efficiency and low energy consumption. It can accurately adapt to different construction environments and provide cost-effective solutions for users in different industries.

Dual scene adaptation, efficiency innovation

1. Down-the-hole expert ZGYX454H: stable and efficient hard rock penetration ZGYX454H is designed for drilling operations under complex geological conditions. It is equipped with a powerful power system that can easily penetrate hard rock layers; with the motor chain propulsion technology, it can efficiently drill holes in various hard rocks. Whether it is mining, water conservancy projects or road construction, it can complete the task excellently.

2. Photovoltaic pioneer ZGYX454G, precise and fast shallow hole layout

ZGYX454G is tailor-made for the booming photovoltaic industry. The integrated design solves the problem of moving the supporting air compressor and reduces the loss of air volume transmission, with excellent energy consumption performance. The strong and stable power system enables it to maintain efficient operation even under high load conditions, with high construction efficiency. The drilling rig has precise positioning, which can meet the needs of large-diameter photovoltaic shallow holes and plays an indispensable role in the construction of photovoltaic power stations.

Powerful configuration to cope with harsh working conditions

Track assembly:

The wide track shoe design reduces the ground pressure ratio, giving the drilling rig excellent walking adaptability.

Powertrain:

Both models use Cummins engines and Chigo's independently developed two-stage compression screw heads, with excellent performance and low energy consumption. ZGYX454H and ZGYX454G can meet the drilling needs of 115-152mm and 152-250mm respectively.

Propulsion system:

ZGYX454H and ZGYX454G both adopt motor chain propulsion, with heavy-duty aluminum alloy propulsion beam assembly, and the drill changing mechanism is equipped with a 5-meter-long Ф89mm diameter drill rod as standard, and a 4+1 drill rod configuration, which can meet the drilling torque and hole depth requirements of different hole diameters.

Cooling system:

The dual-motor dual-fan cooling system is designed with full consideration of the use requirements of cold and tropical low-temperature environments, and is not afraid of cold and heat challenges.

Endurance guarantee:

The 700L large-capacity diesel tank reduces the frequency of downtime and refueling, and continuous operation is more efficient.

Humanized design, labor-saving and worry-free

Easy to operate:

Both drilling rigs adopt an integrated control design of electromechanical and hydraulic integration. The layout of the operating table is ergonomic, and the interface is simple and clear, which reduces the work intensity of the operator. The hydraulic system and control system are simple and stable, making the operation more comfortable, rapid and efficient, and reducing the downtime cost.

Real-time monitoring:

The application of intelligent multi-controller and CAN communication system can monitor the operation status of the equipment in real time, providing a strong guarantee for the safe and reliable operation of the equipment.

Remote control:

The standard IoT cloud system supports remote positioning, locking, real-time data monitoring and parameter adjustment. The construction progress is clear at a glance, and the parameters can be adjusted in real time according to the working conditions.

Convenient maintenance:

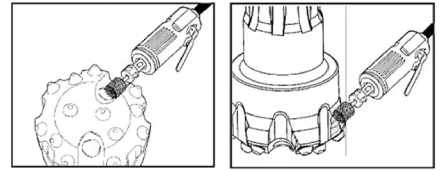

The body layout is optimized and each maintenance point is within reach, which is convenient for maintenance.

Every design of ZGYX454H and ZGYX454G is committed to reducing the overall cost and improving the quality of the project for users. If you want to know more product information, please consult us.

Dual scene adaptation, efficiency innovation

1. Down-the-hole expert ZGYX454H: stable and efficient hard rock penetration ZGYX454H is designed for drilling operations under complex geological conditions. It is equipped with a powerful power system that can easily penetrate hard rock layers; with the motor chain propulsion technology, it can efficiently drill holes in various hard rocks. Whether it is mining, water conservancy projects or road construction, it can complete the task excellently.

2. Photovoltaic pioneer ZGYX454G, precise and fast shallow hole layout

ZGYX454G is tailor-made for the booming photovoltaic industry. The integrated design solves the problem of moving the supporting air compressor and reduces the loss of air volume transmission, with excellent energy consumption performance. The strong and stable power system enables it to maintain efficient operation even under high load conditions, with high construction efficiency. The drilling rig has precise positioning, which can meet the needs of large-diameter photovoltaic shallow holes and plays an indispensable role in the construction of photovoltaic power stations.

Powerful configuration to cope with harsh working conditions

Track assembly:

The wide track shoe design reduces the ground pressure ratio, giving the drilling rig excellent walking adaptability.

Powertrain:

Both models use Cummins engines and Chigo's independently developed two-stage compression screw heads, with excellent performance and low energy consumption. ZGYX454H and ZGYX454G can meet the drilling needs of 115-152mm and 152-250mm respectively.

Propulsion system:

ZGYX454H and ZGYX454G both adopt motor chain propulsion, with heavy-duty aluminum alloy propulsion beam assembly, and the drill changing mechanism is equipped with a 5-meter-long Ф89mm diameter drill rod as standard, and a 4+1 drill rod configuration, which can meet the drilling torque and hole depth requirements of different hole diameters.

Cooling system:

The dual-motor dual-fan cooling system is designed with full consideration of the use requirements of cold and tropical low-temperature environments, and is not afraid of cold and heat challenges.

Endurance guarantee:

The 700L large-capacity diesel tank reduces the frequency of downtime and refueling, and continuous operation is more efficient.

Humanized design, labor-saving and worry-free

Easy to operate:

Both drilling rigs adopt an integrated control design of electromechanical and hydraulic integration. The layout of the operating table is ergonomic, and the interface is simple and clear, which reduces the work intensity of the operator. The hydraulic system and control system are simple and stable, making the operation more comfortable, rapid and efficient, and reducing the downtime cost.

Real-time monitoring:

The application of intelligent multi-controller and CAN communication system can monitor the operation status of the equipment in real time, providing a strong guarantee for the safe and reliable operation of the equipment.

Remote control:

The standard IoT cloud system supports remote positioning, locking, real-time data monitoring and parameter adjustment. The construction progress is clear at a glance, and the parameters can be adjusted in real time according to the working conditions.

Convenient maintenance:

The body layout is optimized and each maintenance point is within reach, which is convenient for maintenance.

Every design of ZGYX454H and ZGYX454G is committed to reducing the overall cost and improving the quality of the project for users. If you want to know more product information, please consult us.

.png)

.png)

.png)