What is reverse circulation drilling method?

Sep 14, 2023

RC, or reverse circulation, drilling is a tried and true drilling method in certain circumstances. Drillers usually use it on large-diameter holes because it is faster and easier to clean the hole. The fluid and cuttings flow up the drill pipe and down the annulus. In softer formations, this causes less washout and makes sampling faster and more accurate because cuttings are not contaminated by sloughing formation off the hole walls. They also come up the drill pipe very fast, giving an accurate formation log.

This article will explain what the reverse circulation drilling method is from three points: the working principle of reverse circulation drilling, the application scenarios of reverse circulation drilling, and the benefits of reverse circulation drilling.

1. How does Reverse Circulation Drilling work?

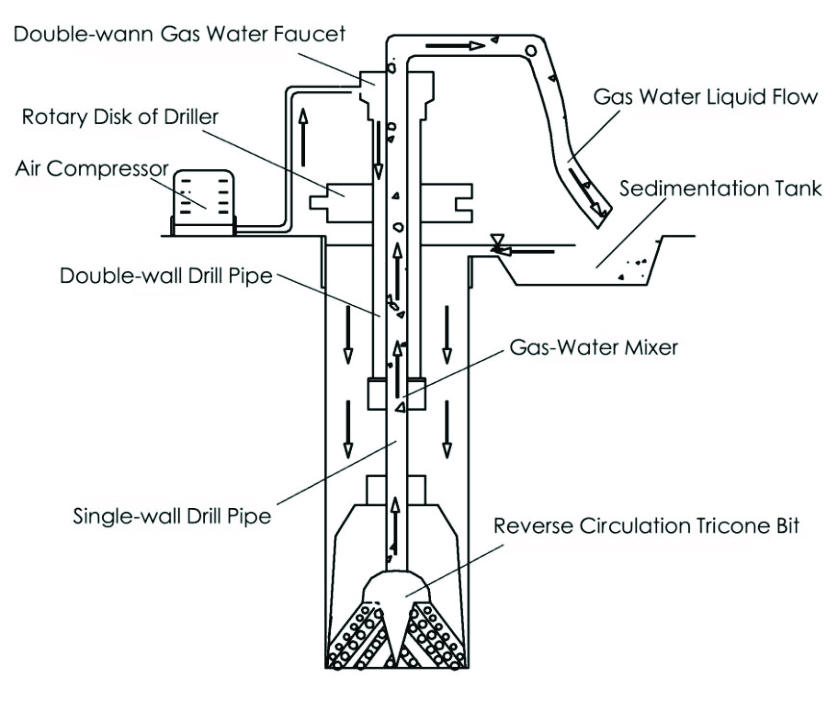

The compressor delivers power to a pneumatic reciprocating piston. The piston, in turn, drives a tungsten-steel drill bit which is purpose designed to be able to crush hard rock.

Similar to air core drilling, drill cuttings are returned to surface inside rods. We achieve this through the use of dual wall drill rods: an outer drill rod with an inner tube. When compressed air is blown through the rod, the volume displaces the air, lifting the samples to the surface.

Once cuttings reach a diverter at the top of the hole, they’re moved through a hose and around the cyclone, which slows the sample down. From the cyclone the sample goes over a splitter that delivers a percentage of the entire sample into a sample bag. The exploration drilling team then collect the samples aligned to the hole depth and lay them out for the client to log, and then transport to the lab for assay.

2. How is Reverse Circulation Drilling Applied?

RC drilling is commonly employed in open-cut mines and used for pit grade control and in delivering useful insight for mine planning and blasting. It has an optimal depth of between 300-500 meters.

RC grade control is extremely effective in defining boundaries between ore bodies and waste rock

RC drilling is ideal for exploration, as it delivers contaminant-free samples, which are collected at the drill itself and can be sent immediately for assessment. It also reduces handling time, which in turn can serve to reduce overall program costs.

3. What are the benefits of Reverse Circulation drilling?

Achieves greater penetration in hard rock than air core drilling, thanks to the percussive force and the strength of the drill bit.

Provides greater sample accuracy, and cuttings are easy to catalogue. The collected samples have an exact location and depth where they were acquired, making it easier to more precisely locate mineral deposits.

Ideal for harsh environments. RC drilling uses approximately 40% less water than diamond drilling, making it a better option for remote area drilling.

Reduced risk of cross-contamination. As the cuttings travel through the drill bit’s inner tube and aren’t introduced to other areas of the drill hole, the samples remain uncontaminated.

Faster and more efficient, reducing costs and providing greater returns. RC drilling achieves higher production rates and can achieve up to 200/300 meters per day. This means that results can be delivered to clients faster, as the drilling itself takes less time. The speed and efficiency involved also reduce rig hours, meaning savings on overall staff hours. Thanks to the power and efficiency of the equipment, RC drilling is more resilient in harsh environments, which makes it a cheaper option overall. In fact, RC drilling has been shown to reduce costs by 25-40%.

This article will explain what the reverse circulation drilling method is from three points: the working principle of reverse circulation drilling, the application scenarios of reverse circulation drilling, and the benefits of reverse circulation drilling.

1. How does Reverse Circulation Drilling work?

The compressor delivers power to a pneumatic reciprocating piston. The piston, in turn, drives a tungsten-steel drill bit which is purpose designed to be able to crush hard rock.

Similar to air core drilling, drill cuttings are returned to surface inside rods. We achieve this through the use of dual wall drill rods: an outer drill rod with an inner tube. When compressed air is blown through the rod, the volume displaces the air, lifting the samples to the surface.

Once cuttings reach a diverter at the top of the hole, they’re moved through a hose and around the cyclone, which slows the sample down. From the cyclone the sample goes over a splitter that delivers a percentage of the entire sample into a sample bag. The exploration drilling team then collect the samples aligned to the hole depth and lay them out for the client to log, and then transport to the lab for assay.

2. How is Reverse Circulation Drilling Applied?

RC drilling is commonly employed in open-cut mines and used for pit grade control and in delivering useful insight for mine planning and blasting. It has an optimal depth of between 300-500 meters.

RC grade control is extremely effective in defining boundaries between ore bodies and waste rock

RC drilling is ideal for exploration, as it delivers contaminant-free samples, which are collected at the drill itself and can be sent immediately for assessment. It also reduces handling time, which in turn can serve to reduce overall program costs.

3. What are the benefits of Reverse Circulation drilling?

Achieves greater penetration in hard rock than air core drilling, thanks to the percussive force and the strength of the drill bit.

Provides greater sample accuracy, and cuttings are easy to catalogue. The collected samples have an exact location and depth where they were acquired, making it easier to more precisely locate mineral deposits.

Ideal for harsh environments. RC drilling uses approximately 40% less water than diamond drilling, making it a better option for remote area drilling.

Reduced risk of cross-contamination. As the cuttings travel through the drill bit’s inner tube and aren’t introduced to other areas of the drill hole, the samples remain uncontaminated.

Faster and more efficient, reducing costs and providing greater returns. RC drilling achieves higher production rates and can achieve up to 200/300 meters per day. This means that results can be delivered to clients faster, as the drilling itself takes less time. The speed and efficiency involved also reduce rig hours, meaning savings on overall staff hours. Thanks to the power and efficiency of the equipment, RC drilling is more resilient in harsh environments, which makes it a cheaper option overall. In fact, RC drilling has been shown to reduce costs by 25-40%.

Related news

-

D Miningwell x TMEIC: Joint Promotion of Intelligent Automation Transformation in Mining Industry - 2025 Cooperation Updates

D Miningwell x TMEIC: Joint Promotion of Intelligent Automation Transformation in Mining Industry - 2025 Cooperation Updates -

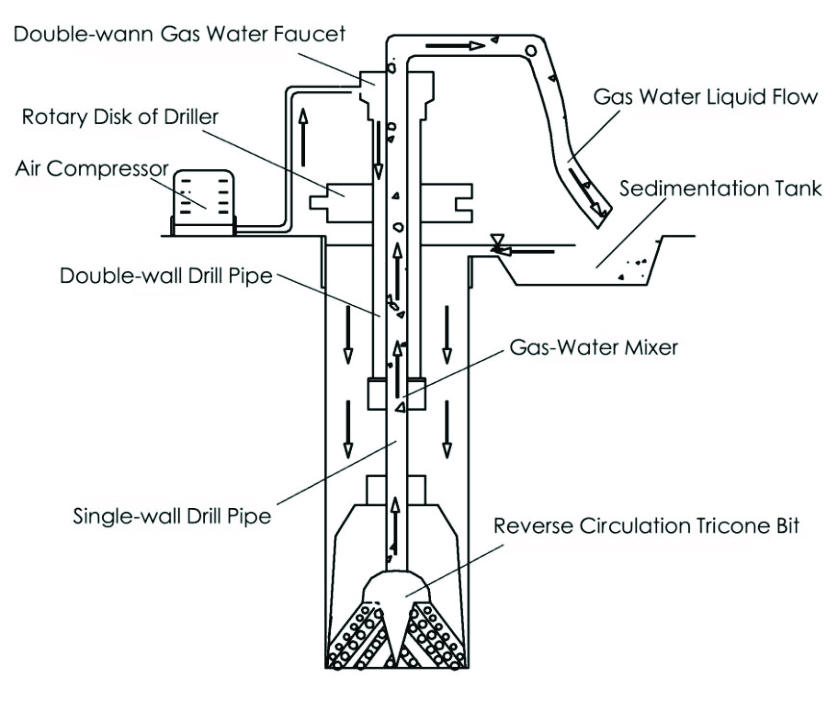

Maintenance of the drill bit

Maintenance of the drill bit -

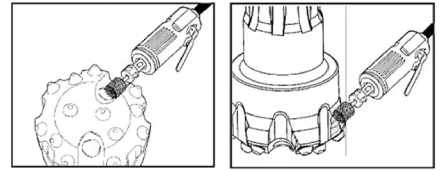

What is a DMiningwell crawler water well drilling rig?

What is a DMiningwell crawler water well drilling rig? -

Professional Water Well Drilling Solutions for Canada — Introducing the MWT350 Truck-Mounted Drilling Rig

.png)