Is top hammer drilling vs down-the-hole drilling?

Jan 03, 2025

Top hammer drilling rig structure:

First, let's talk about the structure of the top hammer drilling rig. It is mainly composed of the drilling arm, the drilling rod propelling beam, the rod changer, the rock drill, the hydraulic control system, the fuel system, the chassis, the cab and other structures. It is generally used in quarries that require drilling and blasting, and is also used in sites such as dividing stone materials and excavating building bases.

DTH hammer structure:

The DTH drilling rig is composed of a rotary mechanism, a lifting mechanism, a pushing mechanism, a supporting mechanism and an impact mechanism. In rock drilling operations, the impactor is submerged into the hole to reduce the energy loss caused by the impact energy transmitted by the drill rod, thereby reducing the influence of the hole depth on the rock drilling efficiency.

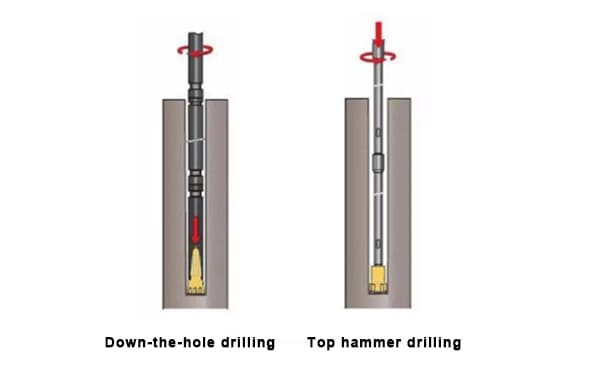

The biggest difference between the two is that the impact force is different in the position, which is why there are two forms.

The difference between the two can be visually seen from the picture. The left is the down-the-hole type, and the impact force directly acts on the tail of the drill bit, which is what we call the drill bit; the right picture is the top hammer type, which is generally hammered by the rock drill. The force is transmitted to the drill bit at the bottom of the hole to break the rock, and the impact force acts on the top of the drill pipe.

The top hammer type appeared earlier than the DTH type. The top hammer type has a wide range of applications. The top hammer type can drill very small holes, and hydraulic impactors can be used to achieve higher efficiency and drilling speed. Its main feature is that it is suitable for small apertures. In small holes and DTH applications, such as tunneling, anchoring, decorative stone, construction, etc., the top hammer type is more popular.

In addition, because the drill rod has to bear the propulsion force and rotational torque, it also bears the action of the shock wave, so it is also easier to deflect.

The DTH hammer is at the bottom of the hole, so the aperture cannot be too small. A major feature of this type of drilling rig is that it is suitable for drilling with large apertures, especially hard rock above 200 MPa, while the top hammer type is more suitable for hardness Work on rocks below 200 MPa.

Related news

-

D Miningwell x TMEIC: Joint Promotion of Intelligent Automation Transformation in Mining Industry - 2025 Cooperation Updates

D Miningwell x TMEIC: Joint Promotion of Intelligent Automation Transformation in Mining Industry - 2025 Cooperation Updates -

D Miningwell x LIUTECH: A Deep Engagement Journey of Corporate Exchange in the Air Compressor Industry

D Miningwell x LIUTECH: A Deep Engagement Journey of Corporate Exchange in the Air Compressor Industry -

How to Choose Tapered Drill Bit and Tapered Drill Rod

How to Choose Tapered Drill Bit and Tapered Drill Rod -

D miningwell Gear Oil Pumps

D miningwell Gear Oil Pumps

.png)

(1).png)

(1).png)

(1).png)

.png)

.png)