How to Select Water Well Drilling Rig?

Aug 05, 2025

At present, the global demand for water well drilling rigs is still increasing day by day, and the design of water well drilling rigs is gradually evolving and optimizing. The more user-friendly design is more conducive to the control of the driller, and the high-quality and high-torque drilling rig also greatly improves the working efficiency of the water well drilling rig.

So in the face of global customers, how do you think to choose a water well drilling rig?

The first reaction of many customers should be: the first price (the cost of the product itself), the second quality or function of the product, and finally whether the supplier is reliable.

.jpg)

Obviously, these concerns are the most correct answers, but still ignore some other important factors. E.g:

Pre-sale, in-sale and after-sale service of drilling rigs.

Before choosing a drilling rig, or our sales manager recommending a drilling rig, we must fully understand the customer's drilling needs, such as address conditions, drilling depth, drilling diameter, rock conditions. This is called pre-sales service.

After fully understanding the customer's drilling needs, the sales manager recommends the most suitable machine to the customer.

From working principle of drilling machine point of view,there are mainly 3 drilling method:

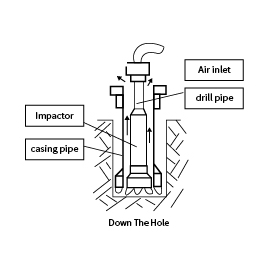

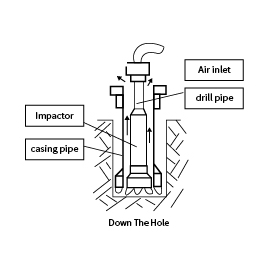

1. Down The Hole drilling method which needs to work with air compressor. It is great method for rock condition.

1. Down The Hole drilling method which needs to work with air compressor. It is great method for rock condition.

2. Rotary drilling with mud pump,it is more economical drilling way and fit very well for soil, sand and clay stratum, for rock its drilling speed will be lower compared to DTH drilling.

3. Auger drilling, it do not need air compressor and mud pump during drilling. But it only can drill the soil, clay and sand.

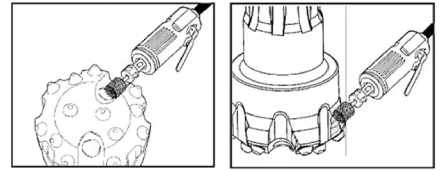

From drilling process point of view, we have 2 drilling method:

.jpg)

1. Direct circulation drilling which the drilling fluid(air or mud) go through drill rod and take the cuttings via the space between outside of drill rod and wall of hole.

2. Reverse circulation drilling, it needs dual wall drilling pipe. The drilling fluid go through the space between inner wall of outer tube and outer wall of inner tube. For cobble stone and sand, soil geological structure, it is most efficient drilling method.

Program:

For large-diameter deep well drilling rigs, MININGWELL technical engineers generally make customized machines according to different drilling requirements.

Provide different solutions for mud pump, air compressor or mechanical transmission for customers to choose.

After helping customers choose the right machine and paying the deposit, we start production and delivery on time and with high quality. We call it in-sale service.

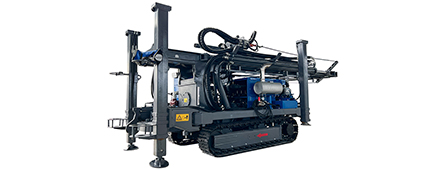

Production:

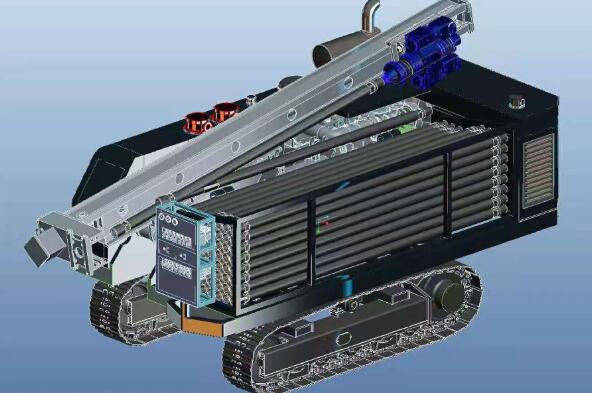

.jpg)

The dminingwell factory has a history of more than 10 years. Every operator and technical engineer will only participate in the production process after serving in the company for more than 5 years. In the first 4 years, we will carefully train every operator as a reserve technical manager. Therefore, each drilling rig can guarantee its production accuracy. At the same time, the dminingwell factory uses high-hardness steel, and some imported bearings are used as the basic structural parts of the drilling rig, which greatly increases the service life and drilling efficiency of the drilling rig.

MININGWELL designers will actually operate drilling experiments every month, and the reasonable design will enable global customers to operate the machine proficiently after they get the machine.

In addition, dminingwell all use TOP brand filter elements to ensure the environmental protection performance of the drilling rig.

Transportation:

The price of well drilling rigs that customers are most concerned about often consists of three parts, the cost of well drilling rigs, the cost of Chinese ports and transportation, and the cost of arriving at the destination port. Our company has close cooperation with the world's top shipping and air express companies, and signed preferential agreements, which greatly saves transportation costs for customers, so that the drilling rigs can be delivered to customers safely and economically.

Machine price is the key factor for people to select suitable drilling rig, it is one time investment.

Price :

The machine’s price increased along with increasing of hole diameter and depth.

From Drilling method point of view, DTH drilling rig is more expensive than coring drilling rig and price of hydraulic drilling rig is higher than vertical shaft drilling rig, which is more mechanical drilling machine

From mobility point of view, truck mounted drill rig cost more than crawler water well drilling rig.

After Sales:

When our drills are transported, we will bring some necessary vulnerable accessories to customers, which can be supplied in time after the accessories are worn out.

Don't underestimate these accessories, because our customers often come from all over the world, and shipping accessories internationally not only affects the use of customers, but also greatly increases the cost. So these accessories often solve this problem easily.

At the same time, our export sales managers and technicians will maintain 24/7 online guidance services, and we will provide video guidance services at any time when customers have any needs.

Above is just some basic knowledge during drilling rig selection. It can be guide for business starter when they plan to buy rig.

So in the face of global customers, how do you think to choose a water well drilling rig?

The first reaction of many customers should be: the first price (the cost of the product itself), the second quality or function of the product, and finally whether the supplier is reliable.

.jpg)

Obviously, these concerns are the most correct answers, but still ignore some other important factors. E.g:

Pre-sale, in-sale and after-sale service of drilling rigs.

Before choosing a drilling rig, or our sales manager recommending a drilling rig, we must fully understand the customer's drilling needs, such as address conditions, drilling depth, drilling diameter, rock conditions. This is called pre-sales service.

After fully understanding the customer's drilling needs, the sales manager recommends the most suitable machine to the customer.

From working principle of drilling machine point of view,there are mainly 3 drilling method:

1. Down The Hole drilling method which needs to work with air compressor. It is great method for rock condition.

1. Down The Hole drilling method which needs to work with air compressor. It is great method for rock condition.2. Rotary drilling with mud pump,it is more economical drilling way and fit very well for soil, sand and clay stratum, for rock its drilling speed will be lower compared to DTH drilling.

3. Auger drilling, it do not need air compressor and mud pump during drilling. But it only can drill the soil, clay and sand.

From drilling process point of view, we have 2 drilling method:

.jpg)

1. Direct circulation drilling which the drilling fluid(air or mud) go through drill rod and take the cuttings via the space between outside of drill rod and wall of hole.

2. Reverse circulation drilling, it needs dual wall drilling pipe. The drilling fluid go through the space between inner wall of outer tube and outer wall of inner tube. For cobble stone and sand, soil geological structure, it is most efficient drilling method.

Program:

For large-diameter deep well drilling rigs, MININGWELL technical engineers generally make customized machines according to different drilling requirements.

Provide different solutions for mud pump, air compressor or mechanical transmission for customers to choose.

After helping customers choose the right machine and paying the deposit, we start production and delivery on time and with high quality. We call it in-sale service.

Production:

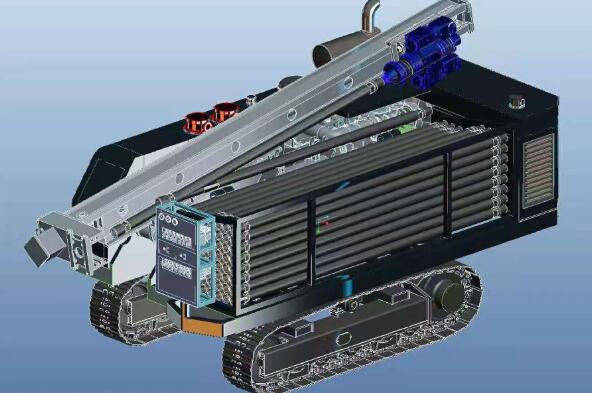

.jpg)

The dminingwell factory has a history of more than 10 years. Every operator and technical engineer will only participate in the production process after serving in the company for more than 5 years. In the first 4 years, we will carefully train every operator as a reserve technical manager. Therefore, each drilling rig can guarantee its production accuracy. At the same time, the dminingwell factory uses high-hardness steel, and some imported bearings are used as the basic structural parts of the drilling rig, which greatly increases the service life and drilling efficiency of the drilling rig.

MININGWELL designers will actually operate drilling experiments every month, and the reasonable design will enable global customers to operate the machine proficiently after they get the machine.

In addition, dminingwell all use TOP brand filter elements to ensure the environmental protection performance of the drilling rig.

Transportation:

The price of well drilling rigs that customers are most concerned about often consists of three parts, the cost of well drilling rigs, the cost of Chinese ports and transportation, and the cost of arriving at the destination port. Our company has close cooperation with the world's top shipping and air express companies, and signed preferential agreements, which greatly saves transportation costs for customers, so that the drilling rigs can be delivered to customers safely and economically.

Machine price is the key factor for people to select suitable drilling rig, it is one time investment.

Price :

The machine’s price increased along with increasing of hole diameter and depth.

From Drilling method point of view, DTH drilling rig is more expensive than coring drilling rig and price of hydraulic drilling rig is higher than vertical shaft drilling rig, which is more mechanical drilling machine

From mobility point of view, truck mounted drill rig cost more than crawler water well drilling rig.

After Sales:

When our drills are transported, we will bring some necessary vulnerable accessories to customers, which can be supplied in time after the accessories are worn out.

Don't underestimate these accessories, because our customers often come from all over the world, and shipping accessories internationally not only affects the use of customers, but also greatly increases the cost. So these accessories often solve this problem easily.

At the same time, our export sales managers and technicians will maintain 24/7 online guidance services, and we will provide video guidance services at any time when customers have any needs.

Above is just some basic knowledge during drilling rig selection. It can be guide for business starter when they plan to buy rig.

.jpg)

.png)