Requirements for Drilling Holes in Blast Hole Drilling Operations

Jun 01, 2022

To successfully drill holes with brazing tools, you need to ensure that the holes are straight, deep, and stable.

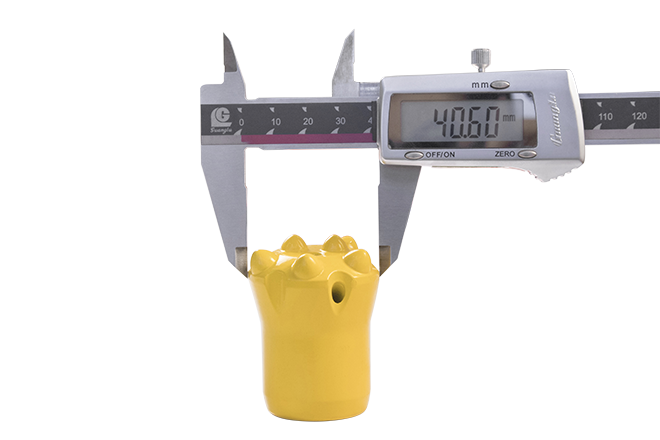

1. Hole Diameter

.jpg)

The size of a drill hole depends on the purpose for which it is being used. Many factors influence the choice of hole for blast hole drilling. The size of the rocks that must be broken down, the type of blast used, the vibration level allowed during blasting, etc. all play a role in determining the quality of the rocks blasted. In larger quarries or large open pit mines, the use of large bore blasting operations often reduces the cost of drilling and blasting per tonne of rock. In underground rock drilling operations, extraction equipment is limited by the amount of space available underground. In water well hole drilling operations, the size of the rock hole depends on the diameter of the pipe or the diameter requirements of the ancillary equipment required by the pump. In the case of rock support holes, the diameter of the different anchors is the determining factor.

2. Depth of the hole

.jpg)

The depth of the hole is influenced by the drilling equipment and in limited spaces only short tools can be used. Short tools in the form of threaded joints are essential for drilling in limited spaces. In the case of rock drilling in blast holes (horizontal or vertical), the depth of the hole is slightly deeper than the theoretical depth or terrace height. In some drilling conditions, where deeper holes are required (50-70 m or more), submerged drilling methods are generally used instead of top hammer percussion drilling, which is more efficient in terms of energy transfer and powder removal in deeper holes.

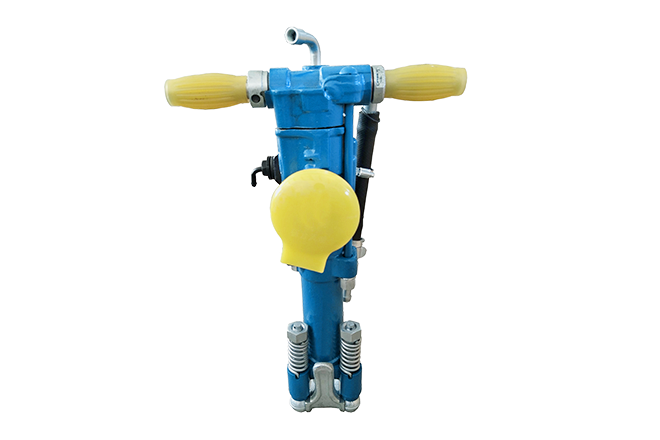

3. Hole straightness

.jpg)

The straightness of the hole is a factor that is highly variable depending on the type of rock and natural conditions, the chosen extraction method and the equipment selected. In horizontal and inclined drilling, the weight of the tool also affects the offset of the hole. When drilling depth blast holes, it is important to keep the drilled hole as straight as possible in order to achieve the desired blasting effect with an accurate charge.

Deeper holes are often drilled in certain types of rock drilling operations where a high degree of straightness is required, such as pipe holes or cable holes. Even water boreholes are very demanding in order to allow for the smooth installation of water pipes and pumps.

The use of different types of guiding equipment, such as guide bits, guide pipes and guide rods, will improve the straightness of the hole. In addition to the offset of the borehole itself, the direction of the hole is also influenced by the degree of adjustment of the propulsion beam and the accuracy of the opening. Therefore considerable precision is required in this respect. Studies have shown that more than 50% of borehole offsets are due to poor propulsion beam adjustment and poor openings.

4. Stability of the hole

.jpg)

Another requirement for the hole drilled is that it remains stable until it has been used for charging or other purposes. Under certain conditions, e.g. when drilling loose material or soft rock areas (which have a tendency to become dislodged and block the hole), it is important to use a drill pipe or hose to descend along the hole being drilled.

Knowing how to drill successfully is the first step, after that we need to improve the efficiency of our drilling, this article "Factors Affecting the Efficiency of Rock Drilling Tools" may help you.

1. Hole Diameter

.jpg)

The size of a drill hole depends on the purpose for which it is being used. Many factors influence the choice of hole for blast hole drilling. The size of the rocks that must be broken down, the type of blast used, the vibration level allowed during blasting, etc. all play a role in determining the quality of the rocks blasted. In larger quarries or large open pit mines, the use of large bore blasting operations often reduces the cost of drilling and blasting per tonne of rock. In underground rock drilling operations, extraction equipment is limited by the amount of space available underground. In water well hole drilling operations, the size of the rock hole depends on the diameter of the pipe or the diameter requirements of the ancillary equipment required by the pump. In the case of rock support holes, the diameter of the different anchors is the determining factor.

2. Depth of the hole

.jpg)

The depth of the hole is influenced by the drilling equipment and in limited spaces only short tools can be used. Short tools in the form of threaded joints are essential for drilling in limited spaces. In the case of rock drilling in blast holes (horizontal or vertical), the depth of the hole is slightly deeper than the theoretical depth or terrace height. In some drilling conditions, where deeper holes are required (50-70 m or more), submerged drilling methods are generally used instead of top hammer percussion drilling, which is more efficient in terms of energy transfer and powder removal in deeper holes.

3. Hole straightness

.jpg)

The straightness of the hole is a factor that is highly variable depending on the type of rock and natural conditions, the chosen extraction method and the equipment selected. In horizontal and inclined drilling, the weight of the tool also affects the offset of the hole. When drilling depth blast holes, it is important to keep the drilled hole as straight as possible in order to achieve the desired blasting effect with an accurate charge.

Deeper holes are often drilled in certain types of rock drilling operations where a high degree of straightness is required, such as pipe holes or cable holes. Even water boreholes are very demanding in order to allow for the smooth installation of water pipes and pumps.

The use of different types of guiding equipment, such as guide bits, guide pipes and guide rods, will improve the straightness of the hole. In addition to the offset of the borehole itself, the direction of the hole is also influenced by the degree of adjustment of the propulsion beam and the accuracy of the opening. Therefore considerable precision is required in this respect. Studies have shown that more than 50% of borehole offsets are due to poor propulsion beam adjustment and poor openings.

4. Stability of the hole

.jpg)

Another requirement for the hole drilled is that it remains stable until it has been used for charging or other purposes. Under certain conditions, e.g. when drilling loose material or soft rock areas (which have a tendency to become dislodged and block the hole), it is important to use a drill pipe or hose to descend along the hole being drilled.

Knowing how to drill successfully is the first step, after that we need to improve the efficiency of our drilling, this article "Factors Affecting the Efficiency of Rock Drilling Tools" may help you.

.jpg)

.png)

.png)

.png)