How do I operate a rock drill correctly?

Aug 02, 2025

The wind drill, or wind-driven rock drill, is a drilling tool that obtains its power through compressed air and is mostly found in mines, concrete, construction sites, etc. The wind drill is compact, single person can operate, the price is not very expensive, is the main force in mountain tunnels, road construction.

I. The working principle of the rock drill

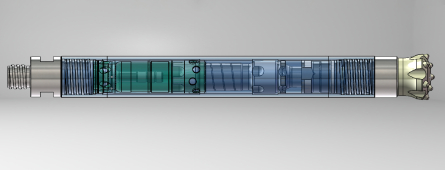

The rock drill is mainly composed of a cylinder, piston assembly, steel brazing rotary part, manipulation valve, air distribution device, flushing and blowing device and other parts.

.jpg)

When the wind drill works, the air is compressed by the cylinder, which provides the impact force, and the piston keeps reciprocating under the impact of the air, impacting the end of the steel braze. The braze gains impact and crushes the rock at the head, forming a dent, which is returned and the rotary section turns the braze at an angle between the next braze strike so that the braze impacts a new dent that fans out from the previous dent.

As the piston continues to move, the brazier continues to impact the rock, forming a circular borehole of some depth.

2. The correct use of the pneumatic jack hammer

So after you buy a wind drilling rig, you have to use and maintain it in accordance with the correct way to minimize our maintenance costs and get a greater rate of return.

(1). When the wind drill rigs leave the factory, they are coated with a large amount of grease in order to prevent the equipment from rusting, and they must be disassembled and cleaned once before use, and reapplied with lubricant before they are assembled for use.

(2). Commonly used lubricants are 20#, 30#, 40# engine oil etc., which are injected into the automatic oil filler to protect the pneumatic jack hammer during operation.

(3). Check the wind pressure and water pressure before starting the machine. The wind pressure is generally 0.4-0.6 MPa and the water pressure is 0.2-0.3 MPa. Too high a wind pressure will increase the burden on the parts and accelerate the damage, while too low a wind pressure will lower the working efficiency. Too high water pressure will pour into the inside of the machine and make the parts easily rusted, too low will not achieve the effect of flushing.

(4). Consumable tapered drill rod When purchasing the equipment, you should buy spare drill rods from the manufacturer, and try to replace them with the original manufacturer, so that the connection size and quality are guaranteed.

I. The working principle of the rock drill

The rock drill is mainly composed of a cylinder, piston assembly, steel brazing rotary part, manipulation valve, air distribution device, flushing and blowing device and other parts.

.jpg)

When the wind drill works, the air is compressed by the cylinder, which provides the impact force, and the piston keeps reciprocating under the impact of the air, impacting the end of the steel braze. The braze gains impact and crushes the rock at the head, forming a dent, which is returned and the rotary section turns the braze at an angle between the next braze strike so that the braze impacts a new dent that fans out from the previous dent.

As the piston continues to move, the brazier continues to impact the rock, forming a circular borehole of some depth.

2. The correct use of the pneumatic jack hammer

So after you buy a wind drilling rig, you have to use and maintain it in accordance with the correct way to minimize our maintenance costs and get a greater rate of return.

(1). When the wind drill rigs leave the factory, they are coated with a large amount of grease in order to prevent the equipment from rusting, and they must be disassembled and cleaned once before use, and reapplied with lubricant before they are assembled for use.

(2). Commonly used lubricants are 20#, 30#, 40# engine oil etc., which are injected into the automatic oil filler to protect the pneumatic jack hammer during operation.

(3). Check the wind pressure and water pressure before starting the machine. The wind pressure is generally 0.4-0.6 MPa and the water pressure is 0.2-0.3 MPa. Too high a wind pressure will increase the burden on the parts and accelerate the damage, while too low a wind pressure will lower the working efficiency. Too high water pressure will pour into the inside of the machine and make the parts easily rusted, too low will not achieve the effect of flushing.

(4). Consumable tapered drill rod When purchasing the equipment, you should buy spare drill rods from the manufacturer, and try to replace them with the original manufacturer, so that the connection size and quality are guaranteed.

.png)