Home » Drilling Machine » D Miningwell HT500 Separated DTH Drill Rig: High-Performance Solution for Mining & Construction Drilling

D Miningwell HT500 Separated DTH Drill Rig: High-Performance Solution for Mining & Construction Drilling

This article focuses on the D Miningwell HT500 Separated DTH (Down-the-Hole) Drill Rig, a specialized mining machine designed for open-pit mines, quarries, construction sites, and more. It details the rig’s core advantages—including structural stability, advanced hydraulic systems, premium component quality, and user-friendly design—and explains how these features meet the high-demand needs of global procurement teams sourcing mining machinery, water well drilling, or core drilling equipment. Additionally, it highlights the rig’s compatibility with self-drilling bolts, further expanding its application scope for complex geological conditions.

Contact US

Get Price

Share:

Content

Why the D Miningwell HT500 Separated DTH Drill Rig Stands Out for Harsh Environments

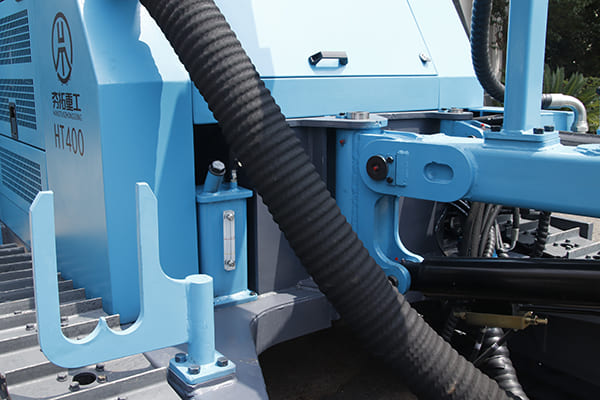

1. Structural Stability: Built for Durability & Smooth Operation

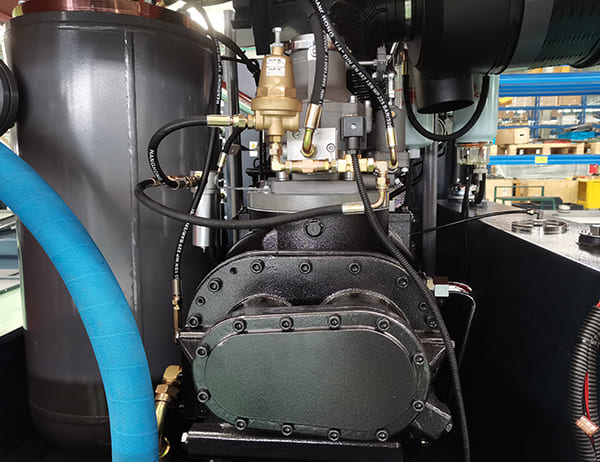

2. Premium Components: Reliability Backed by Global Brands

3. User-Friendly Hydraulic System & Smart Display

4. Engine Protection & Extended Operation Capabilities

5. Compatibility with Self-Drilling Bolts for Complex Formations

Why Global Procurers Choose the D Miningwell HT500

Inquiry

More Seprated DTH drilling rig