All-Round Equipment for Deep-Hole Drilling: D Miningwell MW450 Water Well Drilling Rig, Empowering Water Extraction Projects in Mountainous Rock Formations

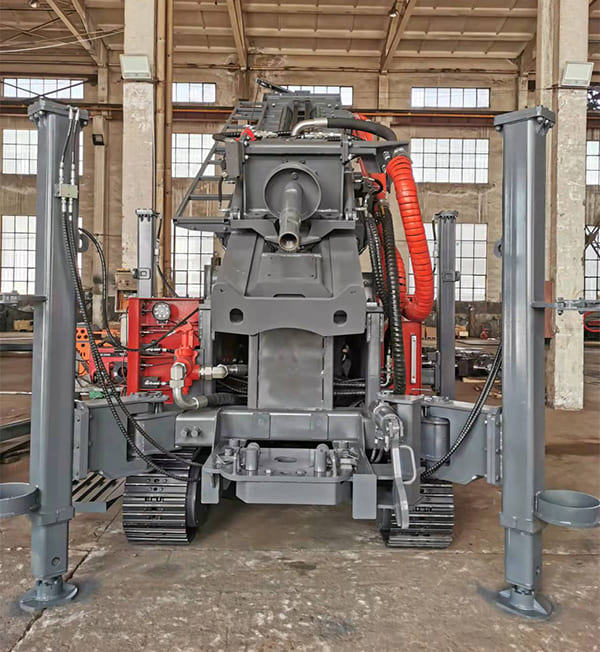

In livelihood and industrial fields such as mountainous water supply, agricultural irrigation, and geothermal development, the performance of deep-hole drilling equipment directly determines whether a project can overcome complex geological constraints and efficiently obtain water or geothermal resources. The MW450 450m Water Well Drilling Rig, launched by D Miningwell (Zhejiang Miningwell Supply Chain Management Co., Ltd.)—a Chinese expert in drilling equipment—boasts core advantages of “strong deep-hole capability, wide terrain adaptability, and efficient and convenient operation”. Equipped with a dedicated compressor, it has become a preferred equipment for water extraction projects in mountainous rock formations, providing reliable solutions for multi-scenario deep-hole drilling needs.

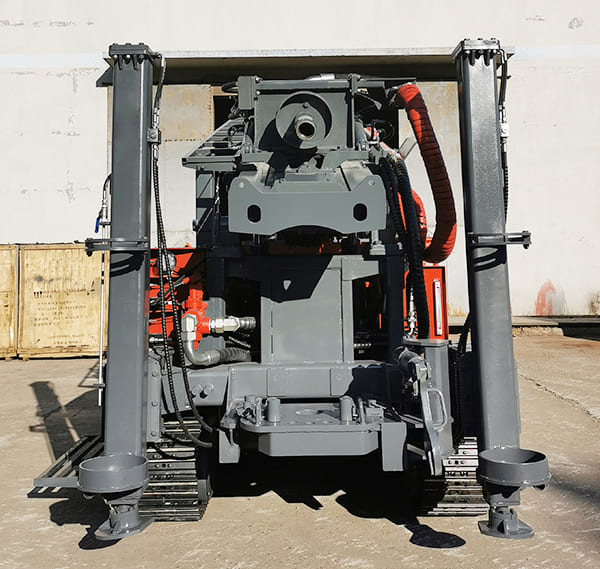

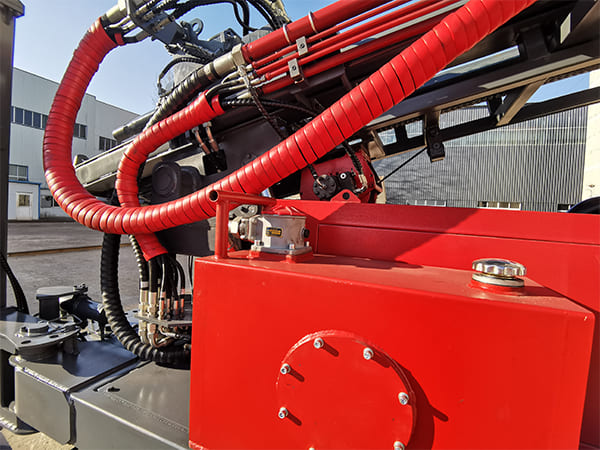

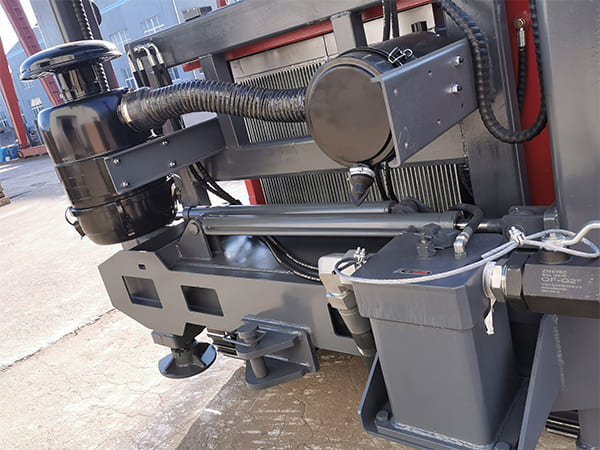

This series of drill rig adopts a excavator crawler chassis and has strong off-road performance. The independent module design allows the drill to be mounted on the truck to increase its mobility. Two speeds of rotating and advancing speed can meet the different needs of soil and rock drilling. Combined positioner, the positioning disc can be adjusted and replaced according to different types of drill pipe and DTH hammer, so as to ensure the accuracy and reliability of the positioning and centering. The hoisting mechanism is convenient for hoisting of drill pipe and DTH hammer, so as to reduce the labor intensity.

| Technical Parameters | |||

| The weight(T) | 9.4 | Drill pipe diameter(mm) | 89 102 |

| The hole diameter(mm) | 140-350 | Drill pipe length(m) | 1.5m 2.0m 3.0m 6.0m |

| Drilling depth(m) | 450 | Rig lifting force(T) | 25 |

| One-time advance length(m) | 6.6 | Rapid rise speed(m/min) | 20 |

| Walking speed(km/h) | 2.5 | Fast feeding speed(m/min) | 40 |

| Climbing angles(Max.) | 30 | Width of loading(m) | 2.8 |

| Equipped capacitor(kw) | 103 | Hoisting force of winch(T) | 2 |

| Using air pressure(MPA) | 1.7-35 | Swing torque(N.m) | 7000-9500 |

| Air consumption(m3/min) | 17-36 | Dimension(mm) | 5950*2100×2600 |

| Swing speed(rpm) | 50-135 | Equipped with hammer | Medium and high wind pressure series |

| The penetration efficiency(m/h) | 15-35 | High leg stroke(m) | 1.6 |

| The engine brand | Weichai engine | ||