Hot Sale Drilling Tools in Chile: A Comprehensive Guide for Mining & Drilling Buyers

Jan 30, 2026

Chile, a global leader in mining (especially copper, lithium, and gold), has a soaring demand for high-performance drilling tools that can tackle its diverse and challenging geological formations—from loose pebbles and dry rocks to large boulders and construction backfill. For buyers of mining machinery, air compressors, water well drills, and core drills, understanding the hot sale drilling tools in Chile is critical to optimizing project efficiency and reducing operational risks. Below is a detailed breakdown of the most sought-after products and their value.

Chilean customer feedback graph

2. Concentric Drilling Tools: The Game-Changer for Complex Formations

The biggest challenge in Chilean drilling projects is dealing with loose, unstable overburden—where hole collapse and tool burial are common. After years of on-site testing, concentric drilling tools (from D Mininwell Drilling Tools) have emerged as the most versatile solution, outperforming eccentric and slider systems in adaptability. Here’s why they’re a top choice:

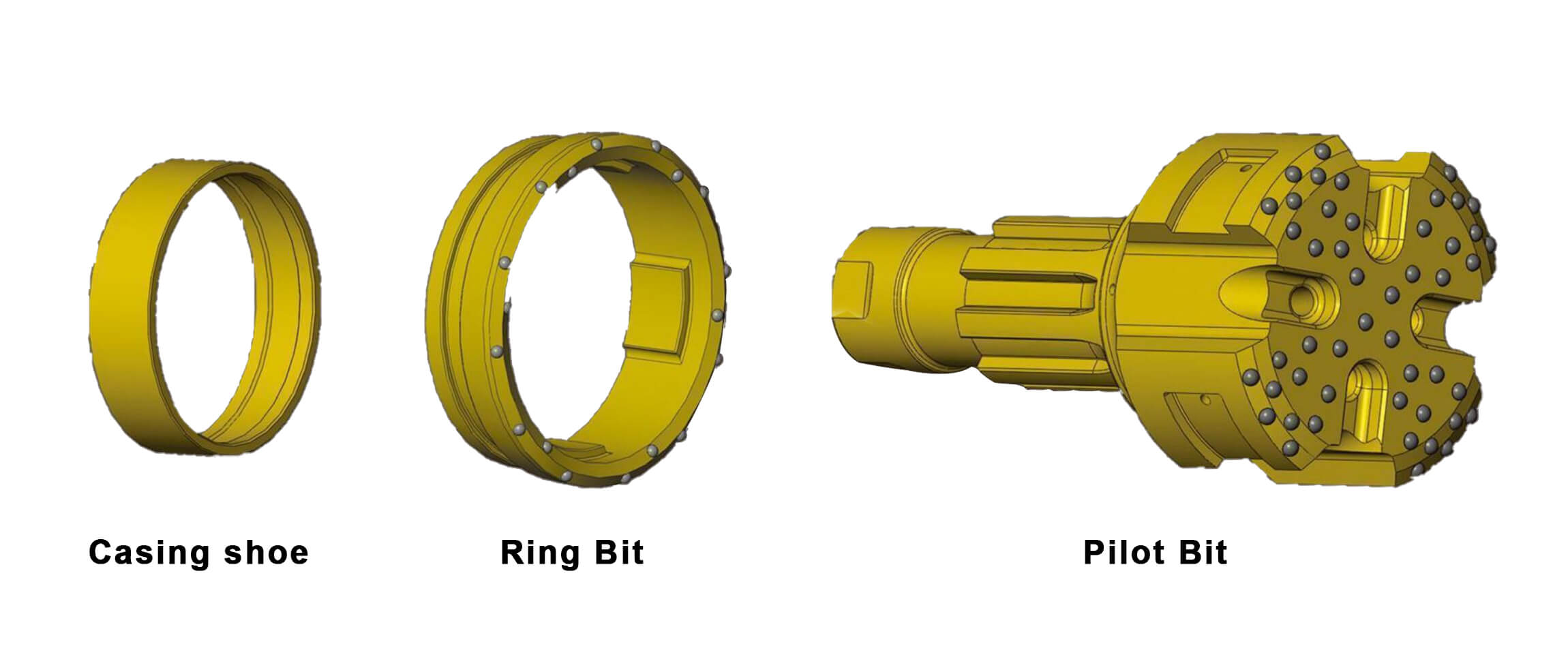

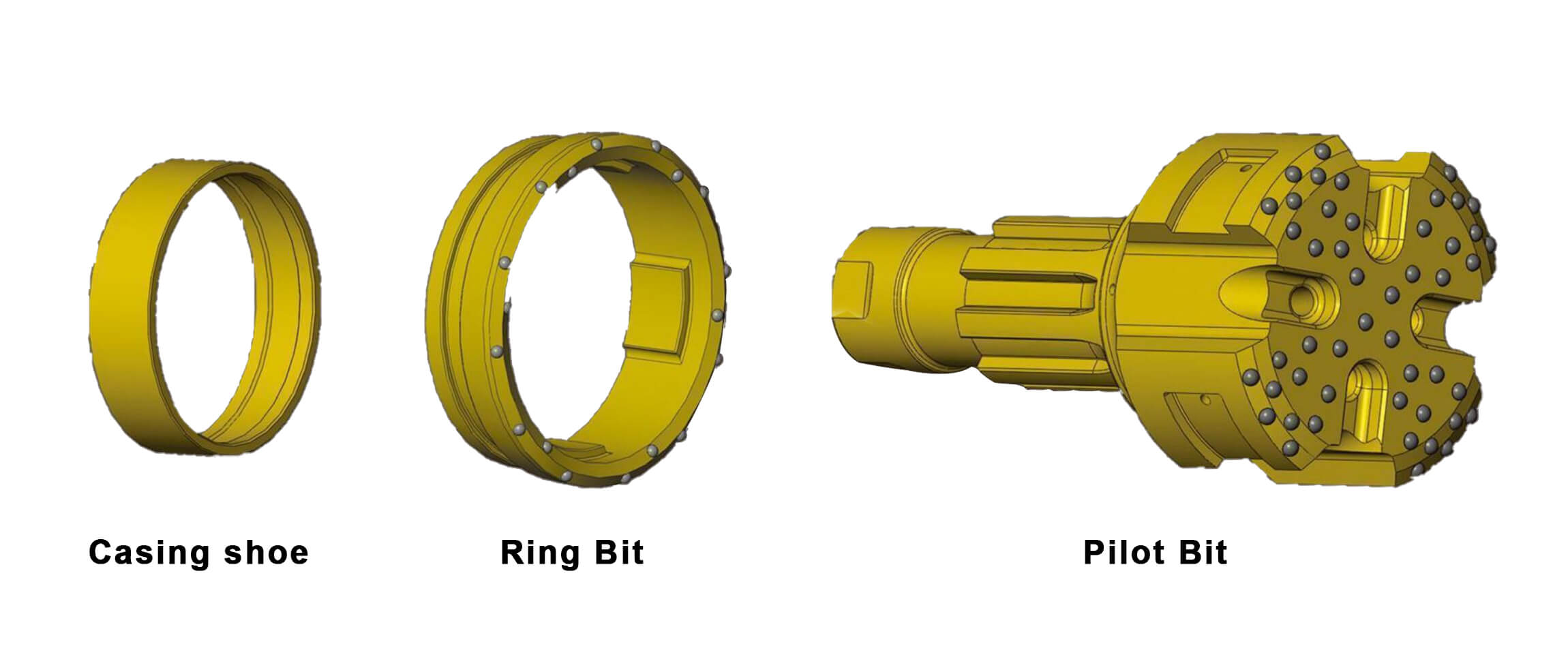

A. Structure of the Concentric Casing System

The system’s modular design ensures simplicity and reliability, consisting of three core components:

Casing Shoe: Connects to the casing tube, protecting the tube from damage during penetration.

Ring Bit: Links the pilot bit to the casing shoe, ensuring alignment and efficient cuttings removal.

Pilot Bit: The heart of the system, equipped with tungsten carbide buttons and flushing grooves to enhance drilling speed and debris clearance.

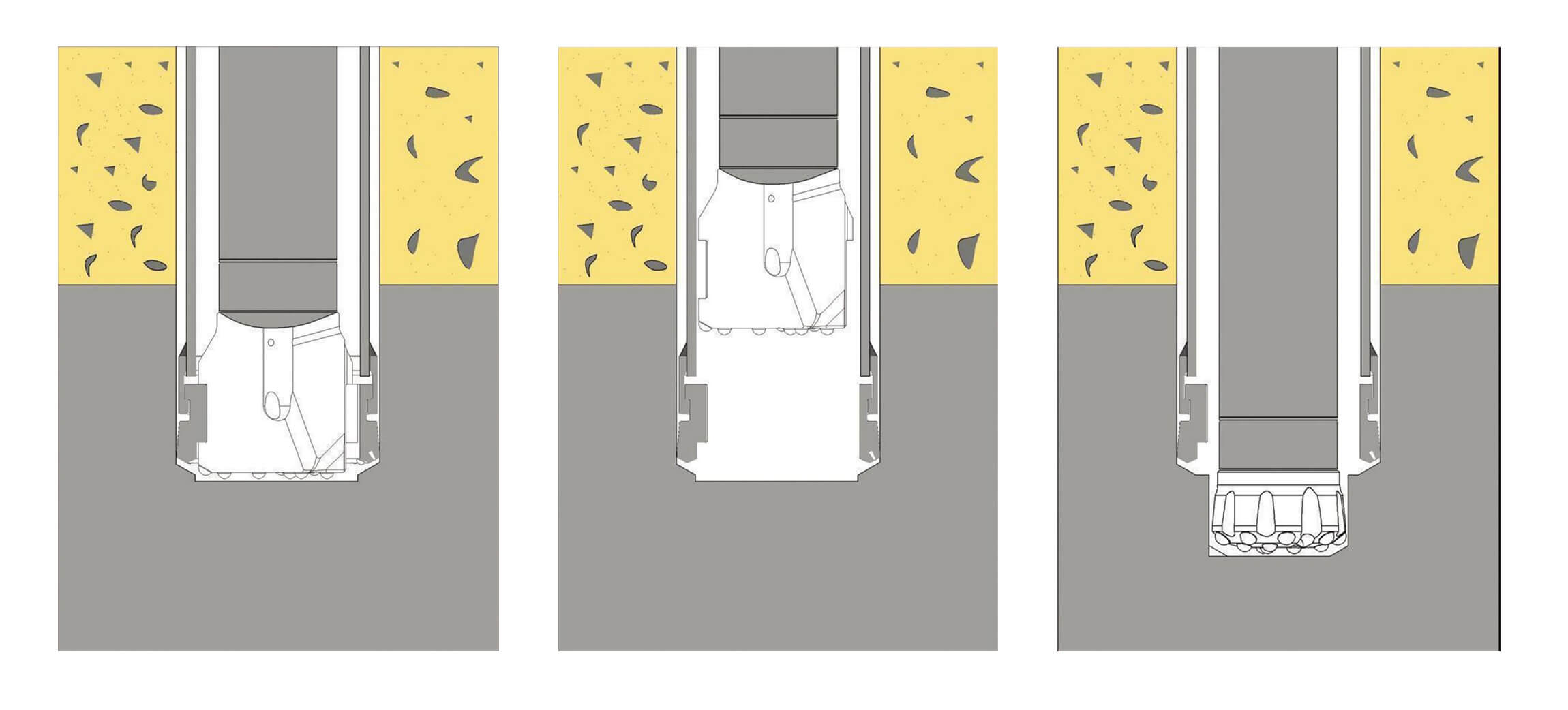

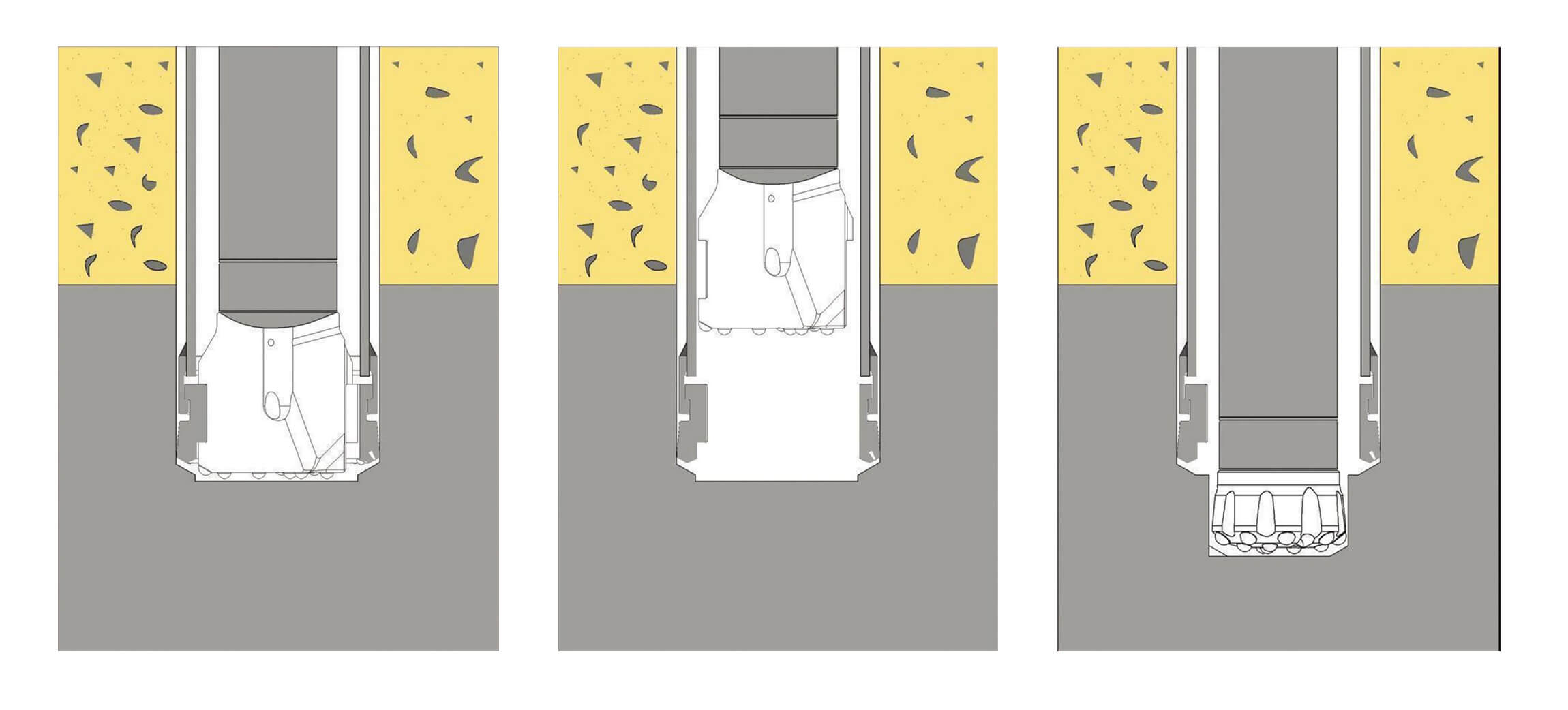

B. Step-by-Step Operation Procedure

Use the concentric system to drill through overburden (pebbles, cracks, or boulders).

Reverse-rotate the DTH hammer to pull out the pilot bit.

Replace the pilot bit with a standard drill bit to continue drilling into harder rock layers.

C. Technical Parameters (Critical for Buyer Selection)

Below is a simplified table of popular concentric drilling tool models in Chile, helping you match tools to your project needs (e.g., hole depth, casing size, or compatible DTH hammers):

Model Casing OD (mm) Casing ID (mm) Wall Thickness (mm) Max Hole Depth (m) Matching DTH Hammer Weight (KG)

P114/9-84 114 94 10 150 COP34/DHD3.5/MW3.5 10

P140/10-97 140 120 10 150 COP44/DHD340(MW4)/SD4 21

P178/12.7-131 178 152.6 12.7 150 COP54/DHD350(MW5)/QL50 32.5

P219/12.7-170 219 193.6 12.7 150 COP64/DHD360(MW6)/SD6 58

P325/12.7-276 325 299.6 12.7 150 COP84/DHD380(MW8)/QL80 135

D. Unbeatable Advantages for Chile’s Conditions

Superior Straightness: Guarantees precise hole alignment, critical for core drilling and foundation pile projects.

Strong Adaptability: Handles complex formations (pebbles, dry rocks, construction waste) without efficiency loss—perfect for Chile’s mining regions.

Low Torque: Reduces wear on drill rods and air compressors, lowering maintenance costs.

Flexible Drilling Angles: Supports vertical, horizontal, and inclined drilling, ideal for water well installation and underground mining.

Urban-Friendly: Low vibration and noise make it suitable for projects near cities (e.g., Santiago), complying with local environmental regulations.

Structure of concentric casing system

Operation procedure

1. Concentric system drilling through overburden

2. Reverse rotation of the hammer and pull out the pilot bit.

3. Replace the pilot bit to normal bit to continue drilling

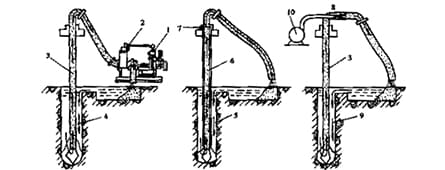

3. How to connect concentric drill bit, down-the-hole hammer and casing shoe

.jpg)

4. Scope of application:

Applicable to overburden with complex dry geological conditions, such as pebbles, cracks, dry rocks, boulders, construction backfill waste, etc. Drilling holes at any angle with high straightness

The maximum hole depth can reach 150 meters

5. Structural advantages:

Straightness: Under different geological structures, the straightness of hole formation can be guaranteed

Adaptability: In complex geological structures, such as pebbles and construction waste, the drilling efficiency can be guaranteed.

Less Torque: Less torque compared to eccentric drilling system.

Easy to Unlock and Relock: Easy to relock after unlocking.

Drilling at any angle: the concentric tubular drilling tool can drill in vertical, horizontal and inclined states.

Environmental protection: Compared with eccentric drilling tools, it is more suitable for construction in urban areas because of its stable drilling, low vibration and low noise.

Factory Photo

.png)

.png)

Chilean customer feedback graph

2. Concentric Drilling Tools: The Game-Changer for Complex Formations

The biggest challenge in Chilean drilling projects is dealing with loose, unstable overburden—where hole collapse and tool burial are common. After years of on-site testing, concentric drilling tools (from D Mininwell Drilling Tools) have emerged as the most versatile solution, outperforming eccentric and slider systems in adaptability. Here’s why they’re a top choice:

A. Structure of the Concentric Casing System

The system’s modular design ensures simplicity and reliability, consisting of three core components:

Casing Shoe: Connects to the casing tube, protecting the tube from damage during penetration.

Ring Bit: Links the pilot bit to the casing shoe, ensuring alignment and efficient cuttings removal.

Pilot Bit: The heart of the system, equipped with tungsten carbide buttons and flushing grooves to enhance drilling speed and debris clearance.

B. Step-by-Step Operation Procedure

Use the concentric system to drill through overburden (pebbles, cracks, or boulders).

Reverse-rotate the DTH hammer to pull out the pilot bit.

Replace the pilot bit with a standard drill bit to continue drilling into harder rock layers.

C. Technical Parameters (Critical for Buyer Selection)

Below is a simplified table of popular concentric drilling tool models in Chile, helping you match tools to your project needs (e.g., hole depth, casing size, or compatible DTH hammers):

Model Casing OD (mm) Casing ID (mm) Wall Thickness (mm) Max Hole Depth (m) Matching DTH Hammer Weight (KG)

P114/9-84 114 94 10 150 COP34/DHD3.5/MW3.5 10

P140/10-97 140 120 10 150 COP44/DHD340(MW4)/SD4 21

P178/12.7-131 178 152.6 12.7 150 COP54/DHD350(MW5)/QL50 32.5

P219/12.7-170 219 193.6 12.7 150 COP64/DHD360(MW6)/SD6 58

P325/12.7-276 325 299.6 12.7 150 COP84/DHD380(MW8)/QL80 135

D. Unbeatable Advantages for Chile’s Conditions

Superior Straightness: Guarantees precise hole alignment, critical for core drilling and foundation pile projects.

Strong Adaptability: Handles complex formations (pebbles, dry rocks, construction waste) without efficiency loss—perfect for Chile’s mining regions.

Low Torque: Reduces wear on drill rods and air compressors, lowering maintenance costs.

Flexible Drilling Angles: Supports vertical, horizontal, and inclined drilling, ideal for water well installation and underground mining.

Urban-Friendly: Low vibration and noise make it suitable for projects near cities (e.g., Santiago), complying with local environmental regulations.

Structure of concentric casing system

3. Why These Tools Are Trusted by Chilean Buyers

Chilean customers (like Joge Acevedo, who rated the tools “100% recommendable”) highlight three key factors:- Durability: Tools withstand Chile’s harsh mining conditions, reducing replacement frequency.

- After-Sales Support: Suppliers offer fast delivery and technical assistance for tool installation/repair.

- Cost-Efficiency: High drilling speed and low maintenance translate to lower per-meter drilling costs.

Operation procedure

1. Concentric system drilling through overburden

2. Reverse rotation of the hammer and pull out the pilot bit.

3. Replace the pilot bit to normal bit to continue drilling

3. How to connect concentric drill bit, down-the-hole hammer and casing shoe

.jpg)

| NO | Items | Description |

| 1 | Casing tube | a. Threaded casing tube,left tuming thread |

| b.Weldied casing tube | ||

| 2 | Drill rod | ThreadAPI[REG/IF/NC |

| 3 | Stabilizer | Thread of stabizer is in keeping with drillng pipe |

| 4 | Hammer | Thread modelAPI REG |

| 5 | Concentric Overburden Drilling System | See the fallowed form for the specs |

4. Scope of application:

Applicable to overburden with complex dry geological conditions, such as pebbles, cracks, dry rocks, boulders, construction backfill waste, etc. Drilling holes at any angle with high straightness

The maximum hole depth can reach 150 meters

5. Structural advantages:

Straightness: Under different geological structures, the straightness of hole formation can be guaranteed

Adaptability: In complex geological structures, such as pebbles and construction waste, the drilling efficiency can be guaranteed.

Less Torque: Less torque compared to eccentric drilling system.

Easy to Unlock and Relock: Easy to relock after unlocking.

Drilling at any angle: the concentric tubular drilling tool can drill in vertical, horizontal and inclined states.

Environmental protection: Compared with eccentric drilling tools, it is more suitable for construction in urban areas because of its stable drilling, low vibration and low noise.

| Technical Parameters of Concentric drilling tools | ||||||||

| Size | OD of casing pipe(mm) | ID of casing pipe(mm) | Wall thickness | Center drill | Perforated | Allow pass | Matching DTH Hammer | Weight (KG) |

| (mm) | bit most | size | drill bit diameter | |||||

| Large outer diameter | (mm) | (mm) | ||||||

| (mm) | ||||||||

| P114/9-84 | 114 | 94 | 10 | 94 | 126 | 84 | COP34/DHD3.5/MW3.5 | 10 |

| P127/10-93 | 127 | 107 | 10 | 105 | 142 | 93 | COP34/DHD3.5/MW3.5 | 16 |

| P140/10-97 | 140 | 120 | 10 | 116 | 161 | 97 | COP44/DHD340(MW4)/SD4/QL40 | 21 |

| P146/10-110 | 146 | 126 | 10 | 124 | 165 | 110 | COP44/DHD340/(MW4)/SD4/QL40 | 22 |

| P168/12.7-127 | 168 | 142.6 | 12.7 | 141 | 188 | 127 | COP54/DHD350(MW5)/SD5/QL50/M50 | 27 |

| P178/12.7-131 | 178 | 152.6 | 12.7 | 150 | 196 | 131 | COP54/DHD350(MW5)/SD5/QL50/M50 | 32.5 |

| P194/12.7-145 | 194 | 168.6 | 12.7 | 166 | 214 | 145 | COP64/DHD360(MW6)/SD6/QL60/M60 | 42.5 |

| P219/12.7-170 | 219 | 193.6 | 12.7 | 191 | 243 | 170 | COP64/DHD360{MW6)/SD6/QL60/M60 | 58 |

| P245/12.7-195 | 245 | 219.6 | 12.7 | 214 | 268 | 195 | COP84/DHD380/(MW8)/SD8/QL80 | 78 |

| P254/12.7-203 | 254 | 228.6 | 12.7 | 224 | 276 | 203 | COP⁸4/DHD380(MW8)/SD8/QL80 | 84.5 |

| P273/12.7-223 | 273 | 247.6 | 12.7 | 241 | 298(305) | 223 | COP84/DHD380(MW8)/SD8/QL80 | 100 |

| P325/12.7-276 | 325 | 299.6 | 12.7 | 292 | 350 | 276 | COP84/DHD380(MW8)/SD8/QL8O | 135 |

| P406/12.7-350 | 406 | 380.6 | 12.7 | 377 | 442 | 350 | DHD112(MW12)/QL120/SD12/NUMA120 | 280 |

| P508/12.7-416 | 508 | 482.6 | 12.7 | 478 | 545 | 416 | QL200/SD18/NUMA180/MW18 | 522 |

| P560/12.7-475 | 560 | 534.6 | 12.7 | 528 | 595 | 475 | QL200/SD18/NUMA180/MW18 | 620 |

| P610/12.7-513 | 610 | 584.6 | 12.7 | 558 | 645 | 513 | QL200/SD18/NUMA180/MW18 | 710 |

Factory Photo

.png)

.png)

.png)