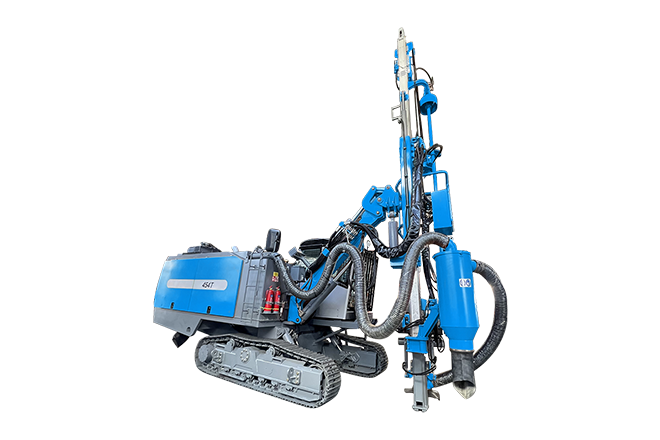

Integrated DTH drilling rig 454T

Brand Name: D miningwell

Minimum Order Quantity: 1 set

Packaging Details: 40HQ-20GP

Delivery Time: 15-20 days

Payment Terms: L/C, T/T, Western Union

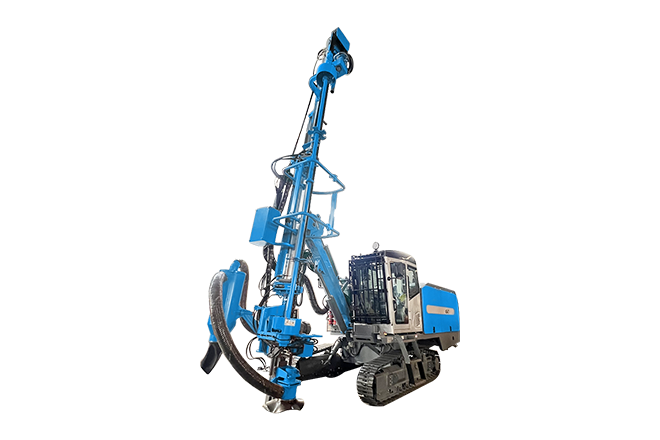

The integrated down-the-hole drill rig is highly efficient and convenient, and is widely used in water conservancy and hydropower projects such as metal and non-metal mining, high-rise building and bridge foundation construction, dam construction and water diversion tunnel construction, as well as slope anchoring projects such as mountain slope reinforcement and foundation pit slope support. It drills holes for various engineering operations, helps improve construction efficiency and quality, and ensures project safety and stability.

Minimum Order Quantity: 1 set

Packaging Details: 40HQ-20GP

Delivery Time: 15-20 days

Payment Terms: L/C, T/T, Western Union

The integrated down-the-hole drill rig is highly efficient and convenient, and is widely used in water conservancy and hydropower projects such as metal and non-metal mining, high-rise building and bridge foundation construction, dam construction and water diversion tunnel construction, as well as slope anchoring projects such as mountain slope reinforcement and foundation pit slope support. It drills holes for various engineering operations, helps improve construction efficiency and quality, and ensures project safety and stability.

.jpg)