Integrated DTH drilling rig D450A

Brand Name: D miningwell

Minimum Order Quantity: 1 set

Packaging Details: 40HQ-20GP

Delivery Time: 15-20 days

Payment Terms: L/C, T/T, Western Union

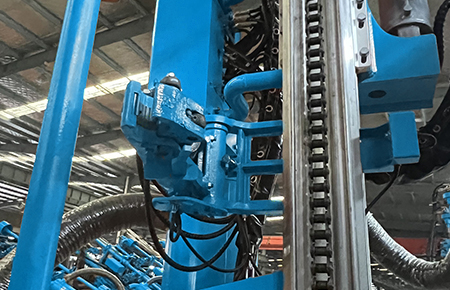

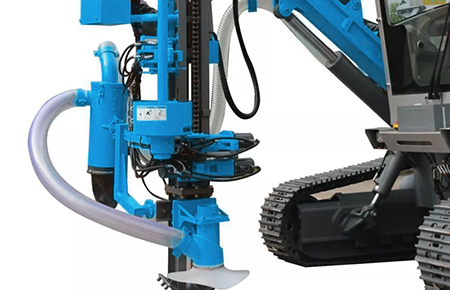

The D450A drilling rig is a remarkable solution in the field. It features a two-stage compression air compressor with an excellent energy efficiency ratio and a powerful 2800N.m rotary head, enabling high-pressure and rapid rock drilling. This not only delivers outstanding fuel economy but also showcases remarkable energy-saving and environmental-friendly qualities. Its relatively light weight and compact size make it extremely convenient for transportation between construction sites and steps. It is highly suitable for various applications in quarries and stone mines, including blasting holes, presplitting holes, damping holes, and ultra-deep hole operations. With its unique combination of performance and portability, the D450A is an ideal choice for professionals in the drilling industry.

Minimum Order Quantity: 1 set

Packaging Details: 40HQ-20GP

Delivery Time: 15-20 days

Payment Terms: L/C, T/T, Western Union

The D450A drilling rig is a remarkable solution in the field. It features a two-stage compression air compressor with an excellent energy efficiency ratio and a powerful 2800N.m rotary head, enabling high-pressure and rapid rock drilling. This not only delivers outstanding fuel economy but also showcases remarkable energy-saving and environmental-friendly qualities. Its relatively light weight and compact size make it extremely convenient for transportation between construction sites and steps. It is highly suitable for various applications in quarries and stone mines, including blasting holes, presplitting holes, damping holes, and ultra-deep hole operations. With its unique combination of performance and portability, the D450A is an ideal choice for professionals in the drilling industry.

.jpg)

.jpg)

.jpg)

.jpg)