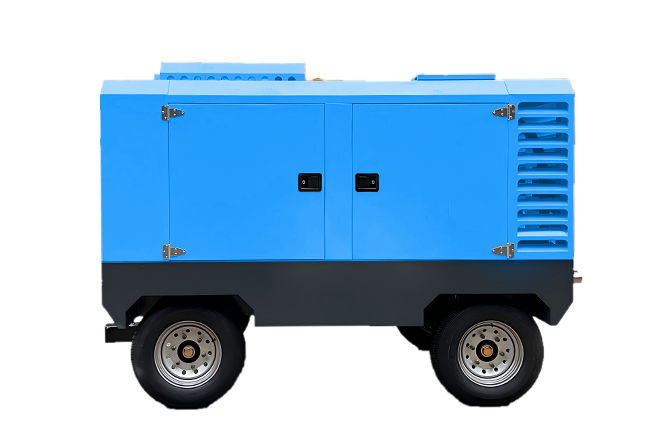

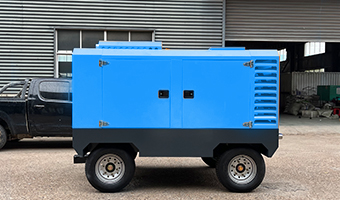

HGT850-8 Diesel portable screw air compressor

Brand Name: D miningwell

Certification: CE, ISO

Minimum Order Quantity: 1 set

Packaging Details: 40HQ-20GP

Delivery Time: 15-20 days

Payment Terms: L/C, T/T, Western Union

The HGT850-8 is a diesel-driven screw air compressor designed specifically for mobile field operations. It uses a Dongfeng Cummins engine (QSB5.9-C220-30) that meets China III emission standards, and is equipped with a single-stage screw compressor and air-cooled refrigeration system. With a rated air volume of 24 cubic meters per minute and an operating pressure range of 5-10 bar, it can meet the air supply needs of outdoor scenarios such as construction, mining, and continuous emergency repairs. The equipment boasts advantages such as a compact size (4200×1750×2300mm), flexible mobility (4-wheel design), and high air cleanliness (outlet oil content ≤5ppm). It also features a wide operating temperature range of -10℃ to 40℃, providing stable and reliable power support for high-intensity outdoor operations.

Certification: CE, ISO

Minimum Order Quantity: 1 set

Packaging Details: 40HQ-20GP

Delivery Time: 15-20 days

Payment Terms: L/C, T/T, Western Union

The HGT850-8 is a diesel-driven screw air compressor designed specifically for mobile field operations. It uses a Dongfeng Cummins engine (QSB5.9-C220-30) that meets China III emission standards, and is equipped with a single-stage screw compressor and air-cooled refrigeration system. With a rated air volume of 24 cubic meters per minute and an operating pressure range of 5-10 bar, it can meet the air supply needs of outdoor scenarios such as construction, mining, and continuous emergency repairs. The equipment boasts advantages such as a compact size (4200×1750×2300mm), flexible mobility (4-wheel design), and high air cleanliness (outlet oil content ≤5ppm). It also features a wide operating temperature range of -10℃ to 40℃, providing stable and reliable power support for high-intensity outdoor operations.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.png)