Successful assembly case of core drilling rig for Iranian customer

May 06, 2025

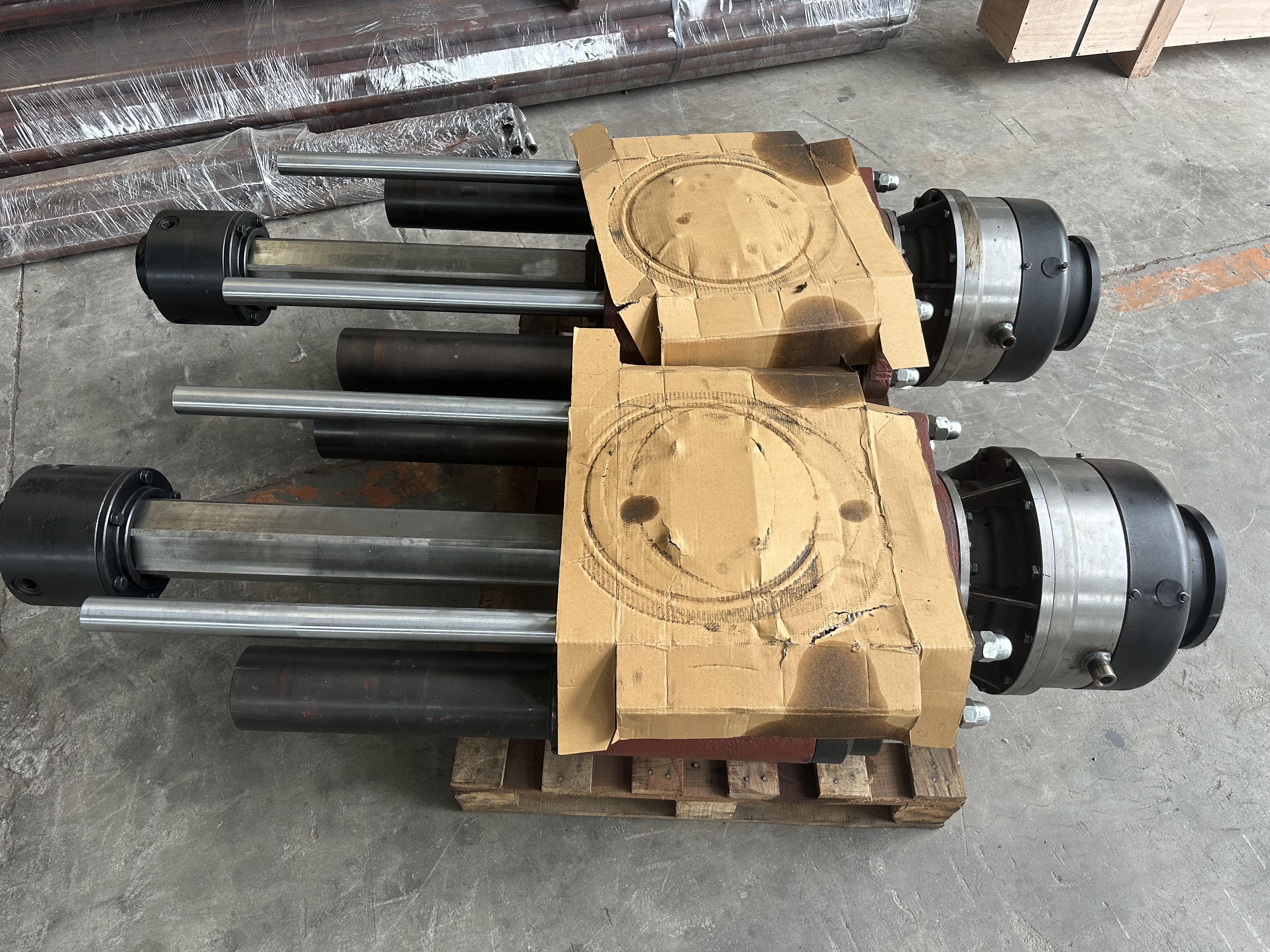

In the field of geological exploration, core drilling rigs are the core equipment for obtaining underground mineral samples. With the growth of global demand for resource development, more and more customers choose to assemble equipment independently to adapt to working conditions more flexibly, reduce costs and achieve technical control. Recently, our cooperation with an Iranian customer is a typical epitome of this trend. The customer successfully assembled an efficient and stable core drilling rig by purchasing core accessories such as transfer case assembly, vertical shaft box assembly (including hydraulic chuck), winch assembly, four-way operating valve, etc. provided by us. This case not only confirms the technical strength of the customer, but also highlights our unique value as a supplier-----providing a complete set of accessories solutions with high compatibility and high reliability.

The Iranian customer is an enterprise focusing on the research and development and engineering services of geological exploration equipment, and has long provided technical support to local mining and energy companies. With the increase of mineral resource exploration projects in Iran, customers urgently need to improve equipment performance to adapt to complex formation environments. However, direct purchase of complete machines faces two major challenges:

1. Cost pressure: The import tariffs on complete machines are high, and transportation costs have increased significantly;

2. Customization requirements: The local operating environment has special requirements for the torque, lifting force and other parameters of the drilling rig, and standard complete machines are difficult to fully adapt.

In this context, the customer decided to adopt the "independent design + key parts procurement" model, which can not only control costs, but also flexibly adjust the performance of the equipment. And our role is to provide them with a "one-stop complete set of parts supply" to ensure seamless collaboration of various components.

The customer put forward two core demands:

1. "Accessory compatibility": The interface standards and power parameters of accessories of different brands must be highly matched to avoid "system conflicts" after assembly;

2. "Long-term stability": Accessories must adapt to high-temperature and dusty field operating environments, with low failure rates and convenient maintenance.

In response to this, our technical team conducted multiple rounds of communication with customers and finally determined the following supporting solutions:

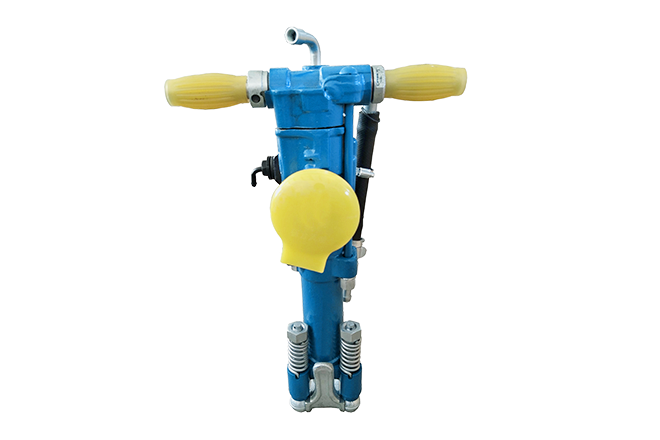

"Transfer case assembly": As the core of power distribution, it adopts modular design and supports multi-gear switching to ensure accurate matching with the customer's selected engine;

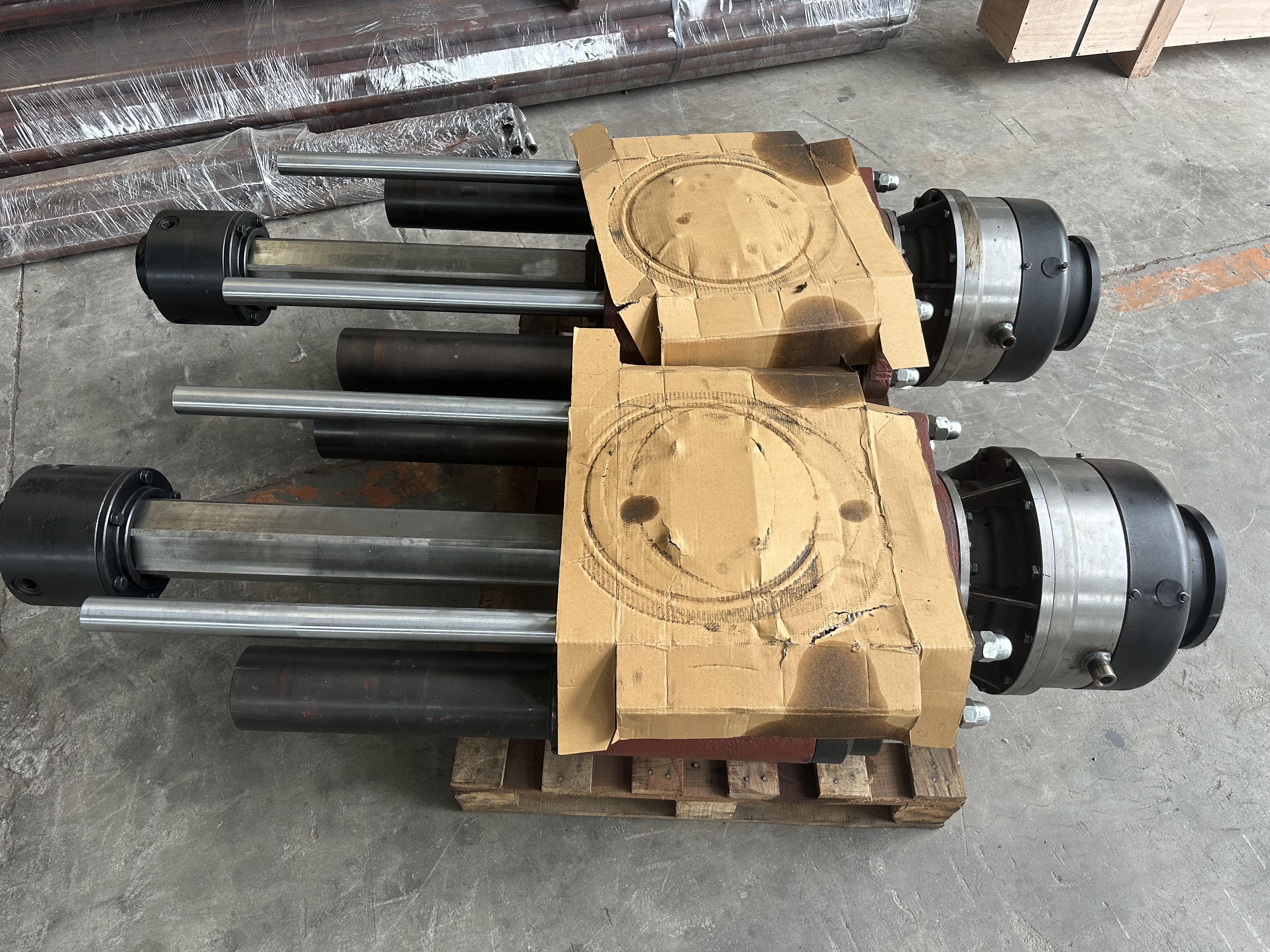

"Vertical shaft box assembly + hydraulic chuck": Integrated structural design, providing high radial load capacity, and hydraulic chuck can achieve rapid clamping and release;

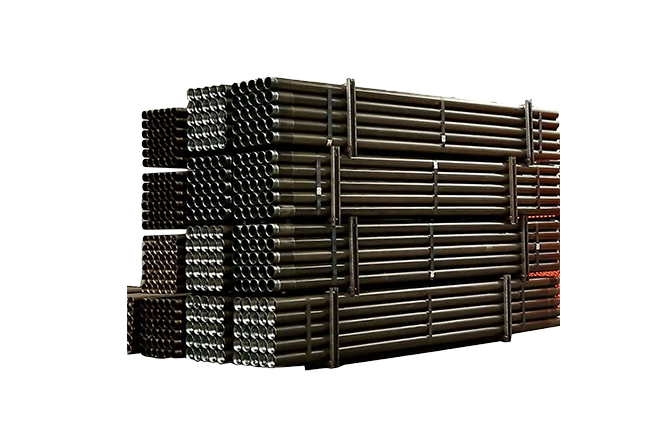

"Wind assembly": Optimize the wire rope cable arrangement structure, improve lifting efficiency and reduce wear;

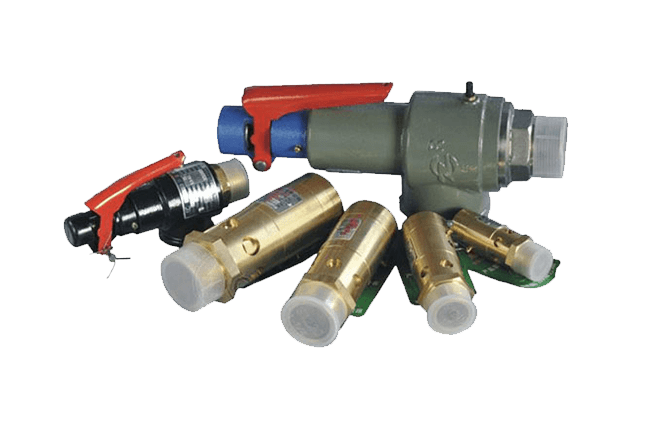

"Four-way operating valve": Integrated hydraulic control system, supports synchronous operation of multiple actuators, and simplifies pipeline layout.

In addition, we additionally provide "3D model drawings, installation torque parameter tables and dynamic load test reports" to help customers predict assembly difficulties and reduce trial and error costs.

Implementation process:

Agile delivery and customs clearance support--remote guidance--customer feedback and continuous optimization

In response to Iran's import and export policies, we adopted the "Turkey transit + local cooperative logistics" solution to complete the delivery of accessories within 21 days and assist customers in completing customs clearance document preparation. Guiding key assembly steps through video connection. Based on the actual experience of customers, we improved the sealing structure of the hydraulic chuck to cope with the local dust environment and further extend the life of accessories. After testing, the key indicators of the assembled core drill exceeded expectations.

Customer evaluation:

"The supplier not only provides high-quality accessories, but also acts as a technical partner, participating in the entire process from solution design to after-sales support. This supporting service gives us confidence in the self-assembly model."

The success of this case confirms the service concept of "accessories are solutions". In the future, we will continue to deepen cooperation with customers in Iran and other emerging markets to promote innovative collaboration in the field of exploration equipment. Whether you need a complete drilling rig or a set of precision accessories, we can be your trusted partner.

Contact us now to get exclusive supporting solutions so that every demand can be accurately implemented!

The Iranian customer is an enterprise focusing on the research and development and engineering services of geological exploration equipment, and has long provided technical support to local mining and energy companies. With the increase of mineral resource exploration projects in Iran, customers urgently need to improve equipment performance to adapt to complex formation environments. However, direct purchase of complete machines faces two major challenges:

1. Cost pressure: The import tariffs on complete machines are high, and transportation costs have increased significantly;

2. Customization requirements: The local operating environment has special requirements for the torque, lifting force and other parameters of the drilling rig, and standard complete machines are difficult to fully adapt.

In this context, the customer decided to adopt the "independent design + key parts procurement" model, which can not only control costs, but also flexibly adjust the performance of the equipment. And our role is to provide them with a "one-stop complete set of parts supply" to ensure seamless collaboration of various components.

The customer put forward two core demands:

1. "Accessory compatibility": The interface standards and power parameters of accessories of different brands must be highly matched to avoid "system conflicts" after assembly;

2. "Long-term stability": Accessories must adapt to high-temperature and dusty field operating environments, with low failure rates and convenient maintenance.

In response to this, our technical team conducted multiple rounds of communication with customers and finally determined the following supporting solutions:

"Transfer case assembly": As the core of power distribution, it adopts modular design and supports multi-gear switching to ensure accurate matching with the customer's selected engine;

"Vertical shaft box assembly + hydraulic chuck": Integrated structural design, providing high radial load capacity, and hydraulic chuck can achieve rapid clamping and release;

"Wind assembly": Optimize the wire rope cable arrangement structure, improve lifting efficiency and reduce wear;

"Four-way operating valve": Integrated hydraulic control system, supports synchronous operation of multiple actuators, and simplifies pipeline layout.

In addition, we additionally provide "3D model drawings, installation torque parameter tables and dynamic load test reports" to help customers predict assembly difficulties and reduce trial and error costs.

Implementation process:

Agile delivery and customs clearance support--remote guidance--customer feedback and continuous optimization

In response to Iran's import and export policies, we adopted the "Turkey transit + local cooperative logistics" solution to complete the delivery of accessories within 21 days and assist customers in completing customs clearance document preparation. Guiding key assembly steps through video connection. Based on the actual experience of customers, we improved the sealing structure of the hydraulic chuck to cope with the local dust environment and further extend the life of accessories. After testing, the key indicators of the assembled core drill exceeded expectations.

Customer evaluation:

"The supplier not only provides high-quality accessories, but also acts as a technical partner, participating in the entire process from solution design to after-sales support. This supporting service gives us confidence in the self-assembly model."

The success of this case confirms the service concept of "accessories are solutions". In the future, we will continue to deepen cooperation with customers in Iran and other emerging markets to promote innovative collaboration in the field of exploration equipment. Whether you need a complete drilling rig or a set of precision accessories, we can be your trusted partner.

Contact us now to get exclusive supporting solutions so that every demand can be accurately implemented!

.jpg)

.png)