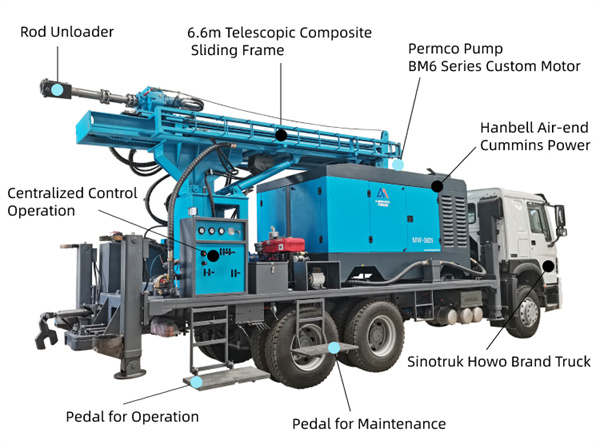

MWT250 Mining Truck Mounted Water Well Drilling Rig for Water Well Drilling

MWT series water well drilling rig is a vehicle-mounted air compressor type water well drilling rig with high efficiency and stability, which is widely used in excavation of domestic water, irrigation water and industrial water.

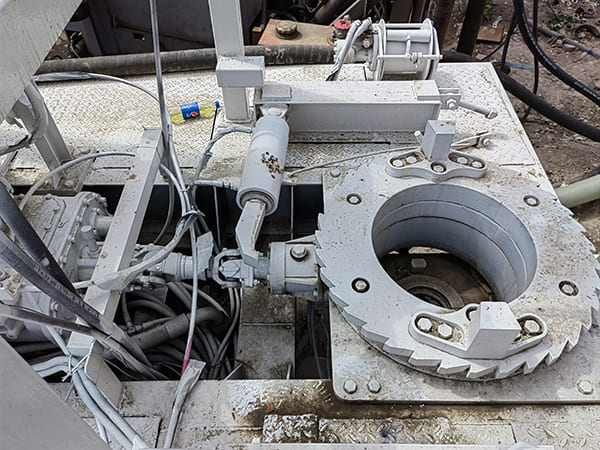

MWT250 water well drilling rig is an intelligent dual-use water and gas drilling rig designed for complex geological conditions. It adopts the modular design concept, and realises the flexible adaptation of drilling scenarios through the dual power system switching technology. Its core innovation lies in the patented rotary head structure, which can seamlessly switch between high-pressure air compressor (pneumatic mode) and high-pressure mud pump (hydraulic mode), breaking through the limitations of the single power system of traditional drilling rigs. Adopting the new four-wheel drive off-road vehicle chassis, matched with the PTO (Power Take-Off) system, realising that the drilling rig and the chassis share the same diesel engine.

Our vehicle-mounted water well drilling rigs are customised products, and customers can customise them according to their actual needs. Customers can choose from chassis brand, boom length, mud pump selection, chassis mounted air compressor and so on. Vehicle-mounted water well drilling rigs are divided into different models according to the drilling depth, and the maximum drilling depth can reach 1500 metres.

The drilling rig has excellent deep-well construction capability, with a maximum drilling depth of 250 metres, and supports drilling diameters ranging from 140 to 254 mm. Its power system is equipped with 17 tonnes of lifting force, suitable for 1.5m, 2.0m and 3.0m standard drill pipes, and the rotary mechanism can achieve 45-70 rpm and 3,300-4,500 Nm torque output. The power configuration is flexible, either Yuchai 70kW special engine can be used, or the chassis power can be shared through the truck PTO system. The hydraulically driven BW250 mud pump provides a flow rate of 250 litres/minute and a working pressure of 2.5 MPa. Together with the 22-bar two-stage compressed air compressor, it forms an air-liquid dual-circulation system to effectively cope with the demands of drilling in complex formations.

The drilling rig features high mobility, high efficiency and multi-scenario applicability: it adopts the new SINO HOWO truck chassis, which realises rapid transfer in complex terrain; it is equipped with high-power hydraulic motor and hydraulic boom drive system, which significantly improves the drilling efficiency. The operation interface is integrated at the back of the machine, and the centralised control panel and the drilling platform’s field of view are designed to be linked together, simplifying the operation process. Outstanding safety performance, hydraulic legs and locking device double to ensure the stability of the operation, and at the same time support water wells, geothermal wells and monitoring wells and other types of drilling tasks, to meet the diversified engineering needs.

With its flexible modular design and efficient power system, MWT250 truck-mounted water well drilling rig is widely used in multi-scenario drilling needs:

Livelihood protection: provide stable water sources for residential areas, rural areas and industrial and mining enterprises, and quickly drill drinking water wells with a calibre of 140-254mm.

Agricultural irrigation: for the needs of agriculture in arid areas, accurately constructing deep irrigation wells up to 250 metres in depth, supporting the continuous operation of high-flow mud pumps;

New energy development: with 22 bar high pressure air compressor, drilling geothermal wells efficiently, helping geothermal energy resources exploration and utilisation;

Engineering monitoring: through the hydraulic outrigger stabilisation system, it accurately constructs monitoring wells, providing data support for geological disaster early warning and infrastructure safety assessment.

Its SINO HOWO chassis and PTO power configuration, to achieve rapid deployment in complex terrain, a single machine can meet diversified engineering needs.

| Model NO. | MWT250 | Certification | CE,ISO 9001:2000 |

| Condition | New | Motor | DC Motor |

| Drill Hole Diameter | 140-254mm | Drill Hole Depth | 250m |

| Bit Type | DTH Bit/Cone Bit/ Drag Bit |

Drilling Way | Impactor |

| Type | Truck Mounted | Drilling Pipe Length | 1m/2m/3m |

| Equipped Engine | Yuchai 70kw or Pto | Feed Stroke | 3.3m |

| Swing Speed | 45-70 Rpm | Swing Torque | 3300-4500(N.M) |

| Rig Lifting Fore | 14t | Transport Package | Nude |

| Specification | 12500*2500*3500 mm |

Trademark | Miningwell |

| Origin | China | HS Code | 8430419000 |

| Production Capacity | 5 Sets Per Month |