D miningwell MWT250 water drilling rig truck for sale well digging rig

The MWT-250 vehicle-mounted water well drilling rig uses a new SINO HOWO truck chassis and is equipped with a 22 bar two-stage compression high-pressure air compressor. Its lifting force can reach 17 tons, and it can drill water wells with a maximum depth of 250 meters.

Application: Drill Water Wells

Capacity

Hole Diameter : 140 – 325 mm (51/2″ – 13″)

Maximum Depth: 250 m @ 203 mm (8″) diameter

Drilling Method : DTH and Rotary Drilling

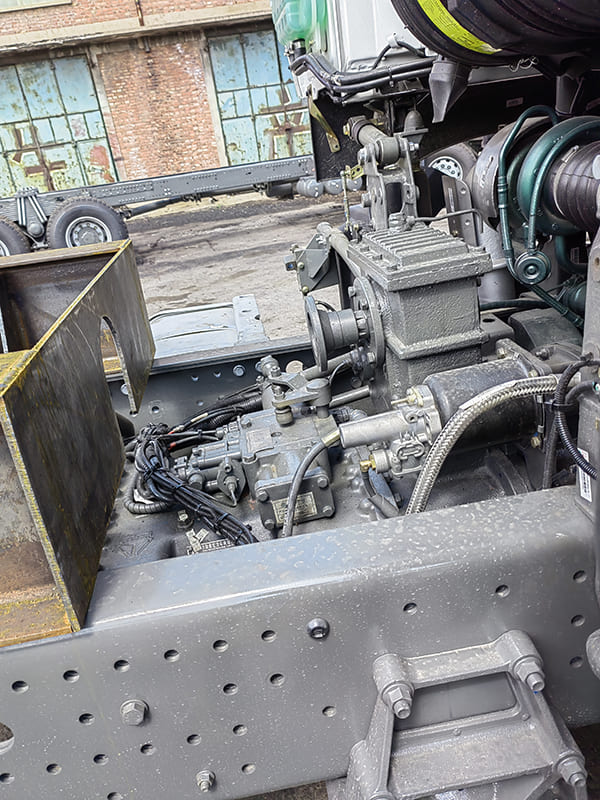

Prime mover

Option 1: Use the PTO system and use the transfer gearbox to take the power from the truck engine (290hp/336hp/371hp) to drive the hydraulic system.

Option 2: Use a 75kw diesel engine for the individual configuration of the drilling rig.

Platform Structure

Heavy I and C section welded steel structure covered with 5mm chequered plate

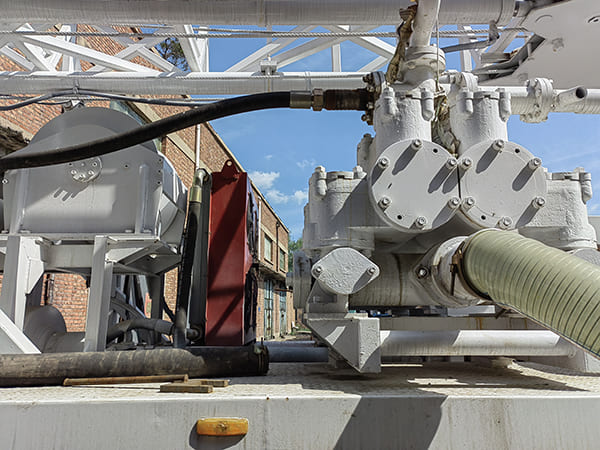

Mast Assembly

The compound drill boom is lifted by double oil cylinders, which increases the lifting force and reduces the transport size.

Mast Overall Length : 8000 mm

Rotary Head Travel : 6600mm

Rod Handling :6m

Centralizer Opening : 14″ (355mm)

Mast Raising Cylinder :Mast is raised and lowered by double hydraulic cylinder

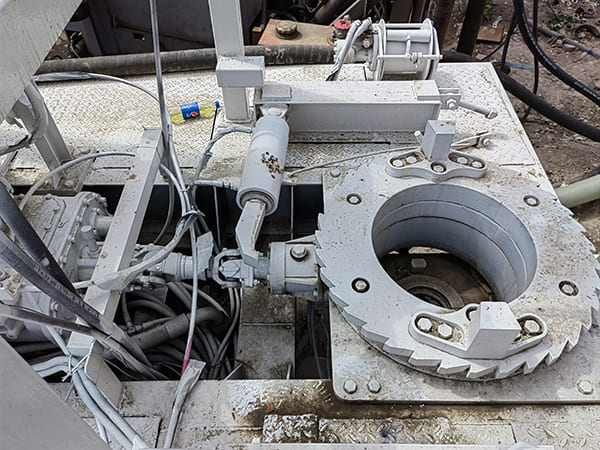

Feed System

1 x Double acting hydraulic cylinder with 1:3 rope reeving system

Pull Up Force : 17Ton

Pull Down Force : 10 – 110Tom

Pull Up Speed : 25 m/min

Pull Down Speed : 30 m/min

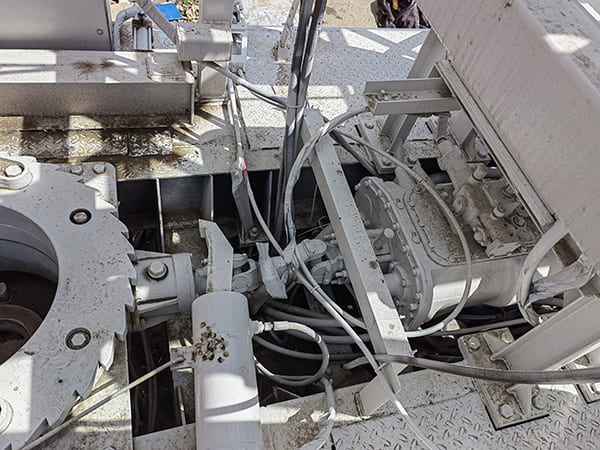

Rotary Head Assembly

Self-developed fabricated steel body with spur gear reduction

and oil bath lubrication, driven by dual hydraulic motors.

Maximum Torque : 6000 Nm

Rotation Speed : 66 – 135 rpm Fine controlled

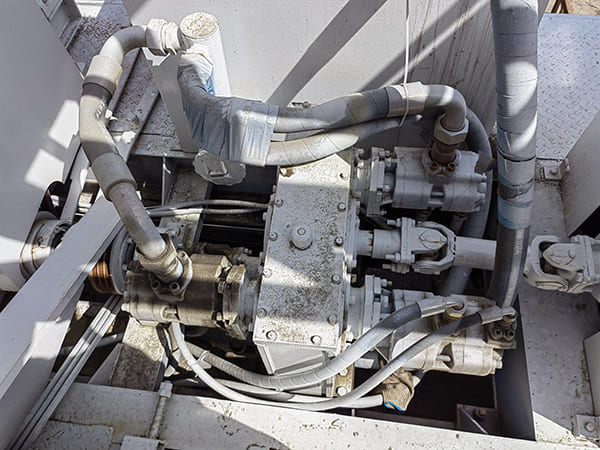

Hydraulics

2 x Fixed displacement pump for Feed and Rotation

1 x Fixed displacement pump for Mud pump

3 x Fixed displacement pump for Hydraulic cooler, Auxiliary operations and Micro feed.

Maximum System Pressure : 2900 psi (200 bar)

Hydraulic Oil Cooler : 70 gpm

Hydraulic Tank Capacity : 600 litres

Control Panel

Centralized control panel is at rear end of the equipment for convenient view of drill table provided with all necessary gauges, control system and emergency switch. Locking arrangement is provided for the safety of control panel.

Breakout Wrench

4 x Hydraulic levelling jacks are provided for quick setting and Levelling Jackslevelling with heavy duty telescopic guides. Locking check valves for safety with adequate capacity to withstand load.

Water/ Foam Injection Pump (optional)

Hydraulic operated water injection triplex pump with necessary fittings, pressure regulator, flow regular, check valve and suction filter are provided.

Maximum Flow : 80 Ipm

Maximum Pressure : 40 kg/sq.cm

Single Rod Changer

Manually operated single rod changer to couple drill pipe to Rotary head

Winch

Hydraulic operated auxiliary winch to load drill pipe into rod changer with a lifting capacity of 5 ton.

Welding Machine

Hydraulic driven semi brushless welding alternator is provided for welding casing pipes

Recommended Weld rod size : 2.5 mm to 5 mm only

Weld current : 300 amps @ 60% duty cycle

Optional single phase : 6.0 kVA @ 220v, 50 Hz

Airline Lubricator

A positive acting venturi type inline lubricator is provided for injecting oil to the down hole hammer.

Tank capacity : 15 litres

Working pressure : 350 psi

Recommended Air Compressor

MININGWELL/ATLAS COPCO/LIUTECH

Air Compressor Capacity:

1100CFM – 25 BAR – 309kW engine

900CFM – 22 BAR – 228kw engine

Mud Pump

Hydraulic operated BW 250 Mud Pump

Stroke : 4″ (100 mm)

Engine power: 15 Kw

Displacement (Max recommended) : 250L/min

Maximum working Pressure : 2.5Mpa

Additional Fitments

Night Lights, Tools box, Hammer stand

User Manual

Manual for Operation, Maintenance and Spare Parts

Truck Option

SINO HOWO Truck: 6*4/6*6/8*4

Dongfeng Truck: 6*4/6*6/8*4

Shacman truck: 6*4/6*6/8*4