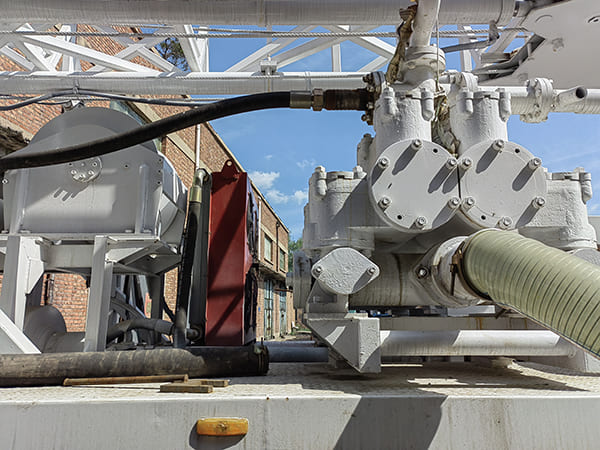

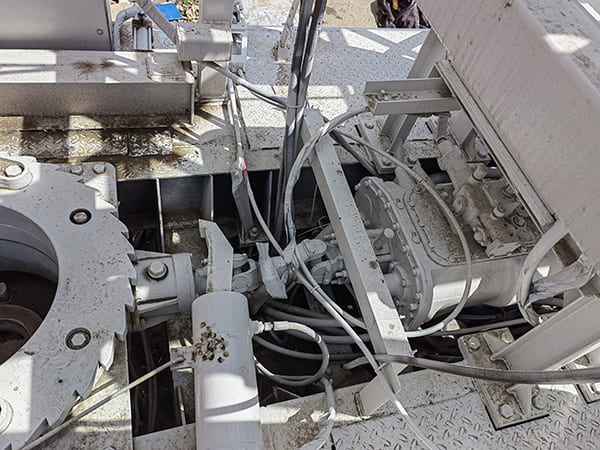

MW300G Professional Manufacturer Industrial Reverse Circulation Drilling Rig

MW300G Reverse Circulation Drilling Rig: Efficient and Stable Engineering Tool

In modern engineering construction, efficient and stable drilling equipment is the key to the smooth progress of the project. MW300G Reverse Circulation Drilling Rig, with its excellent technical parameters and outstanding performance characteristics, has become an ideal choice for mining, infrastructure construction, water well drilling and other fields.

Its drilling diameter ranges from 89-150mm, and the maximum drilling depth reaches 300m, which is applicable to the drilling needs of a variety of stratum conditions, whether it is loose and soft soil or hard rock layer, all can work efficiently. The main engine has a lifting force of 20T and a maximum rotary torque of 9000-4500N-m, providing strong power output; the feed efficiency of 20-35m/h ensures fast drilling and shortens the working period. Recommended air consumption is 18-35m³/min with 1.7-3.0MPa working air pressure, which not only guarantees the drilling efficiency, but also adapts to different air source conditions; the climbing capacity is 21°, and the crawler chassis design makes it move flexibly in complex terrain, and it is easy to cope with mountainous areas, construction sites and other scenarios. The machine weighs 8.2 tonnes and measures 7000×1950×2500mm, which ensures stability while taking into account the convenience of transport and on-site deployment; the 92kW engine power provides long-lasting power and reduces energy consumption and maintenance costs.

Reverse circulation technology: the core of efficient and environmentally friendly drilling The working principle of the reverse circulation drilling rig is the key to its efficiency. Compared with traditional positive circulation, this technology creates an upward flow through air or mud medium from inside the drill pipe to transport rock chips directly to the surface, which has the following advantages:

- Improved drilling efficiency: rock chips are discharged quickly, reducing clogging in the hole and avoiding repetitive drilling, which is especially effective in large-diameter and deep-hole operations.

- Environmental protection and economy: reduce the use of mud, reduce the risk of environmental pollution, while saving mud disposal costs.

- Stratigraphic adaptability: suitable for dry strata or groundwater-rich environments, flexible switching by adjusting air pressure and media.

Second, the application scene: the preferred equipment for multi-discipline projects MW300G reverse circulation drilling rig is widely used by virtue of its technical parameters and reverse circulation technology:

Mining: High-efficiency drilling helps the exploration and mining operations of mineral deposits, and the high torque and deep hole capacity meet the demand of resource development.

Infrastructure construction: bridge pile foundation, foundation reinforcement and other projects, rapid hole formation to improve construction efficiency and reduce project costs.

Water well and geothermal drilling: precise control of drilling diameter and depth, suitable for rural water supply, urban geothermal development and other livelihood projects.

Emergency rescue: its mobility and climbing ability make it play an important role in geological exploration and emergency well drilling in disaster rescue.

Third, equipment highlights: reliability and intelligence coexist In addition to technical parameters and core technology, MW300G reverse circulation drilling rig also has the following design highlights:

Rugged structure: blue and grey industrial paint, strong corrosion resistance; key components are made of high-strength steel to extend the service life of the equipment.

As an efficient, stable and environmentally friendly reverse circulation drilling rig, the MW300G provides a reliable solution for engineering construction with its excellent technical parameters and intelligent design. Whether in harsh geological environments or complex engineering needs, it can help projects move forward efficiently with its outstanding performance, which is a ‘powerhouse’ in the field of modern engineering.