MININGWELL MW180 Water-Cooled Well Drilling Rig: Performance, Price, and Applications

In fields such as water well drilling, geological exploration, and small-scale mining, an efficient, reliable, and adaptable drilling rig is essential. MININGWELL’s MW180 water-cooled well drilling rig, with its outstanding performance, reasonable price, and wide range of applications, has become an ideal choice for many engineering teams.

MININGWELL MW180 main parameters

| Technical Parameters | MW-180 | MW-250 | MW-280 | MW-300 |

| Drill depth(m) | 180 | 250 | 280 | 300 |

| Drill diameter(mm) | 140-254 | 140-254 | 140-305 | 140-325 |

| Equipped Engine | YC 65kW | YC 70kW | YC 75kW | YC 85kW |

| Drill pipe diameter(mm) | φ76 φ89 | φ76 φ89 | φ76 φ89 | φ76 φ89 φ102 |

| Drill pipe length(m) | 1.5/2.0/3.0 | 1.5/2.0/3.0 | 1.5/2.0/3.0/6.0 | 1.5/2.0/3.0 |

| Swing speed(rpm) | 45-70 | 45-70 | 40-70 | 40-70 |

| Swing torque(N.m) | 3200-4600 | 3300-4500 | 4500-6000 | 5700-7500 |

| Rig lifting force(T) | 12 | 14 | 17 | 18 |

| Weight(T) | 5.2 | 4.1 | 7.6 | 7.2 |

| Dimension(mm) | 4000*1630*2250 | 4000*1800*2400 | 5900*1850*2360 | 4100*2000*2500 |

Excellent Performance, Efficient Drilling

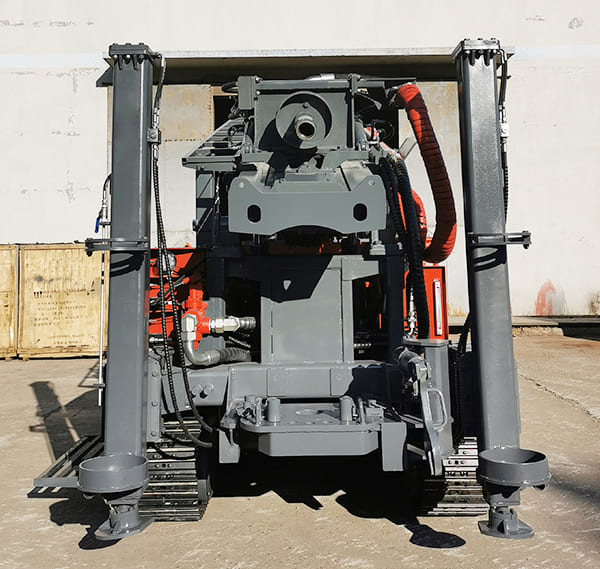

The MW180 water-cooled well drilling rig boasts a range of impressive performance features, enabling it to handle complex drilling conditions. Equipped with a powerful 55kW turbocharged engine from the renowned Guangxi Yuchai company, it provides stable and sufficient power for all drilling operations, ensuring smooth drilling in diverse geological conditions.

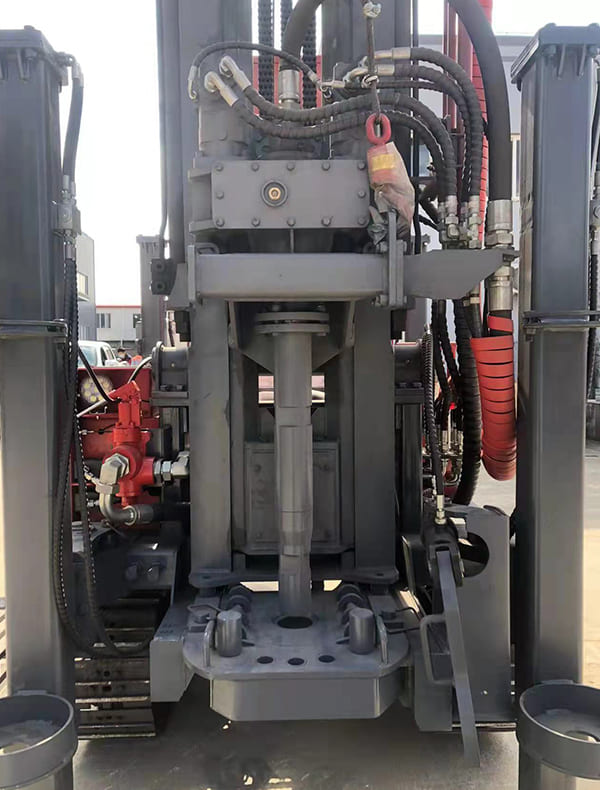

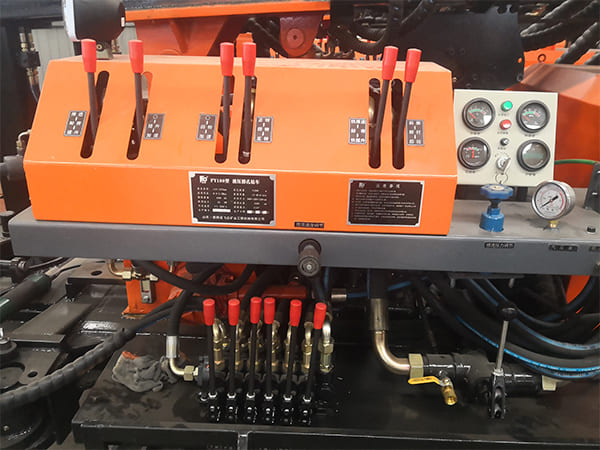

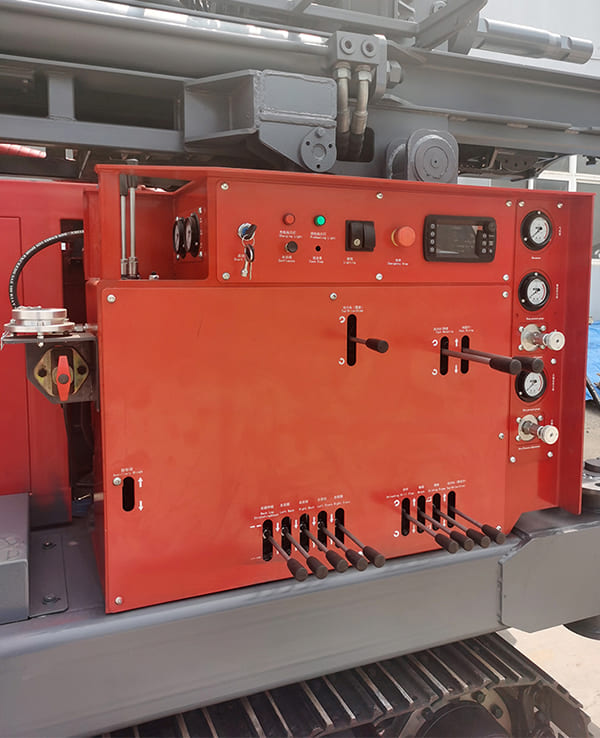

The rig’s rotary head utilizes an integrated cast gearbox design and dual motors. This not only provides powerful torque for efficient drilling, but also significantly enhances durability and reduces maintenance costs. During actual drilling, the high torque easily handles hard rock formations, enabling fast and stable drilling and effectively improving drilling efficiency.

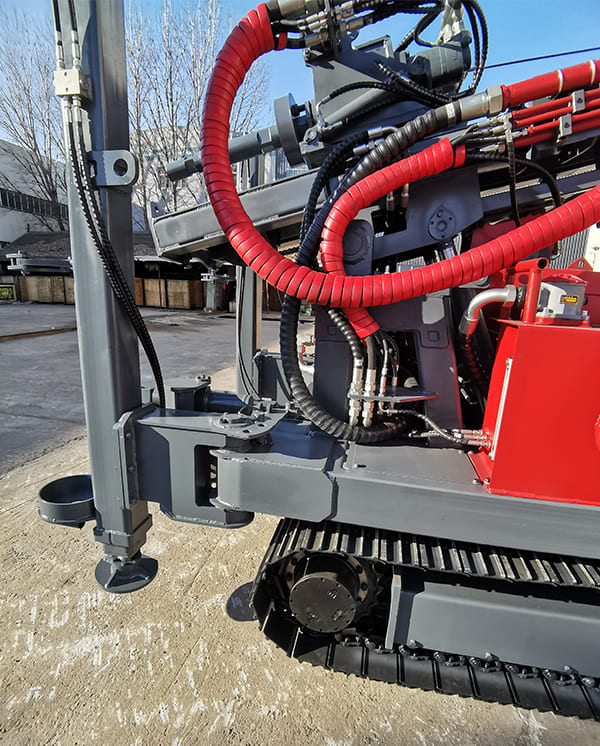

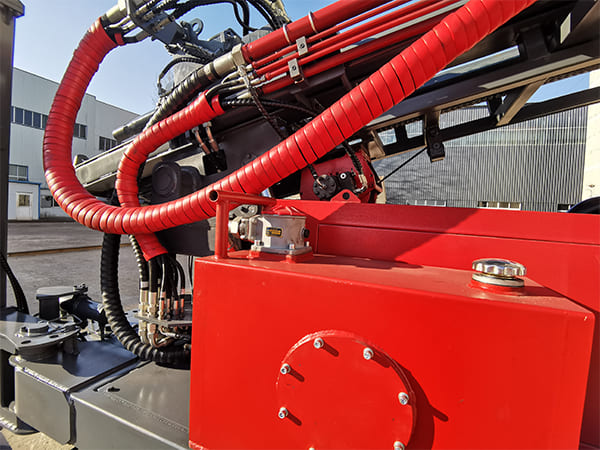

The rig’s propulsion and lifting systems also perform exceptionally well. The rig features a patented composite boom design, boasting a compact design yet a long stroke. Combined with dual hydraulic cylinders, it provides a powerful lifting force of up to 14 tons. This design not only easily lifts heavy drill pipe and drill bits, but also allows for flexible adjustment of lifting force to suit stratum conditions, ensuring smooth drilling operations. Limiters installed on the lift arms effectively protect the hydraulic cylinders, preventing equipment damage from improper operation and providing a strong guarantee for safe production. Furthermore, each hydraulic oil line is covered with a protective casing, further extending the service life of the lines and reducing downtime caused by damage.

The crawler travel system of the MW180 drill rig is also meticulously designed. Its crawler drive gears and reduction gearbox significantly extend the service life of the equipment. The rig’s chassis draws on the design concepts of professional excavator chassis, offering excellent durability and strong load capacity. The wide crawler chain plates minimize damage to concrete pavement during operation, effectively minimizing the impact on the surrounding environment when operating in urban areas, where pavement protection is a high priority, demonstrating excellent adaptability.

Flexible Adaptability, Wide Application

This drill rig has a wide range of applications, meeting the needs of various engineering scenarios. For water well drilling, the MW180, with its stable performance and precise drilling control, can efficiently drill standard wells, providing a reliable water source for industrial production and residential use. Whether searching for groundwater resources in arid regions or constructing community water supply wells in cities, the MW180 demonstrates its strengths.

In geological exploration, it can penetrate deep underground to obtain core samples from various strata, providing crucial data for geological research and mineral resource exploration. Its precise drilling depth control and excellent verticality ensure representative samples, helping researchers accurately analyze stratigraphic structure and geological characteristics.

For small-scale mining operations, the MW180 is capable of drilling prospecting holes before mining and blasting holes during mining. Its flexible design and powerful drilling capabilities are fully utilized within the confined working space of mines, improving mining efficiency and safety.

In addition, the MW180 drill rig, with its versatility and superior performance, provides strong support for the smooth progress of various projects, including grouting holes for defense construction, foundation reinforcement, monitoring holes for hydropower cofferdams, and grouting holes for dam seepage control. Reasonable Pricing, High Cost-Effectiveness

The price of the MW180 water-cooled well drilling rig varies depending on configuration, sales channel, and purchase quantity. Generally speaking, its market price is flexible, meeting the needs of different customer groups. For individual units, the FOB price ranges from approximately $10,800 to $12,000. On some platforms, a single unit may cost as much as $15,500, but when purchasing five or more units, the price is discounted to $15,000 per unit.

For wholesale purchases, the price typically ranges from $20,650 to $21,560 per unit. This pricing approach not only takes into account the purchasing power of small and medium-sized engineering teams, lowering their purchasing threshold through a low minimum order quantity and reasonable unit price, but also offers price discounts for bulk purchases for large projects, enabling customers to obtain high-quality drilling equipment at a more economical cost. This fully demonstrates the price competitiveness and cost-effectiveness of the MW180 drilling rig. Worry-Free Purchasing, Attentive Service

MININGWELL is committed to providing customers with comprehensive, high-quality services, making purchasing the MW180 drilling rig hassle-free. Regarding product quality, the MW180 drilling rig has obtained international certifications such as CE and ISO. From raw material selection to production process control and final product inspection, every step strictly adheres to international standards, ensuring that the equipment’s materials, performance, and safety indicators meet industry-leading standards, ensuring customers can use it with confidence.

During packaging and transportation, standard export packaging is used, which is waterproof, moisture-proof, shock-resistant, and pressure-resistant. This effectively prevents damage to the drilling rig during long-distance transportation, ensuring safe and intact delivery. For standard specifications, the delivery time is typically 7 to 10 days. For urgent orders, the company also offers expedited production services to minimize delivery time and meet customer project schedule requirements.

MININGWELL offers a wide range of payment options, including L/C (Letter of Credit), T/T (Telegraphic Transfer), Western Union, and other internationally accepted payment methods. This fully considers the trade settlement habits and needs of customers in different regions around the world, reduces cross-border procurement risks, and provides customers with a convenient and secure payment experience.