Home » Drilling Machine » Crawler water well drilling rig » A Flexible and Efficient Drilling Tool: D Miningwell MW180 Series Rotary Small Drilling Rigs, Unlocking New Possibilities for Multi-Scenario Drilling

A Flexible and Efficient Drilling Tool: D Miningwell MW180 Series Rotary Small Drilling Rigs, Unlocking New Possibilities for Multi-Scenario Drilling

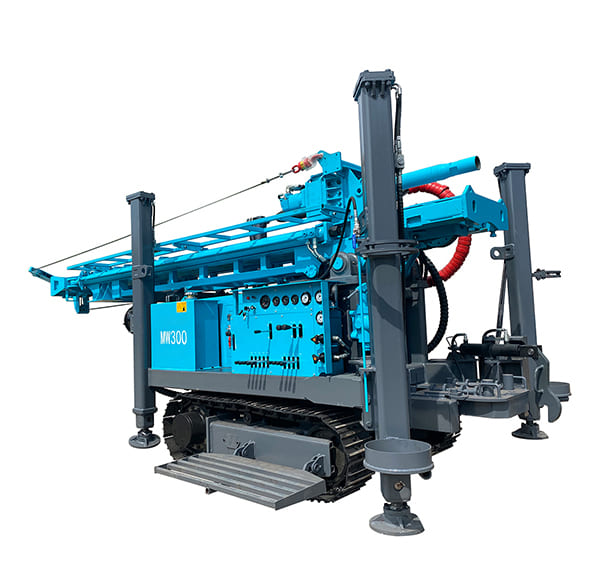

In scenarios such as water well drilling, geological monitoring, and water conservancy project reinforcement, a drilling equipment that combines portability, efficiency, and stability often serves as an “accelerator” for project progress. The MW180 Series Rotary Small Drilling Rigs, launched by D Miningwell (Zhejiang Minsheng Supply Chain Management Co., Ltd.)—a professional Chinese mining equipment supplier—boast core advantages of “multi-functionality, low energy consumption, and easy maintenance”. They meet diverse drilling needs ranging from civilian water wells to industrial infrastructure, providing reliable solutions for engineering projects of various scales.

Contact US

Get Price

Share:

Content

| Technical Parameters | MW-180 | MW-250 | MW-280 | MW-300 |

| Drill depth(m) | 180 | 250 | 280 | 300 |

| Drill diameter(mm) | 140-254 | 140-254 | 140-305 | 140-325 |

| Equipped Engine | YC 65kW | YC 70kW | YC 75kW | YC 85kW |

| Drill pipe diameter(mm) | φ76 φ89 | φ76 φ89 | φ76 φ89 | φ76 φ89 φ102 |

| Drill pipe length(m) | 1.5/2.0/3.0 | 1.5/2.0/3.0 | 1.5/2.0/3.0/6.0 | 1.5/2.0/3.0 |

| Swing speed(rpm) | 45-70 | 45-70 | 40-70 | 40-70 |

| Swing torque(N.m) | 3200-4600 | 3300-4500 | 4500-6000 | 5700-7500 |

| Rig lifting force(T) | 12 | 14 | 17 | 18 |

| Weight(T) | 5.2 | 4.1 | 7.6 | 7.2 |

| Dimension(mm) | 4000*1630*2250 | 4000*1800*2400 | 5900*1850*2360 | 4100*2000*2500 |

Inquiry

More Crawler water well drilling rig