Home » DTH hammer » D Miningwell DTH Hammer Parts (Sub): High-Performance Components for Mining & Drilling Operations

D Miningwell DTH Hammer Parts (Sub): High-Performance Components for Mining & Drilling Operations

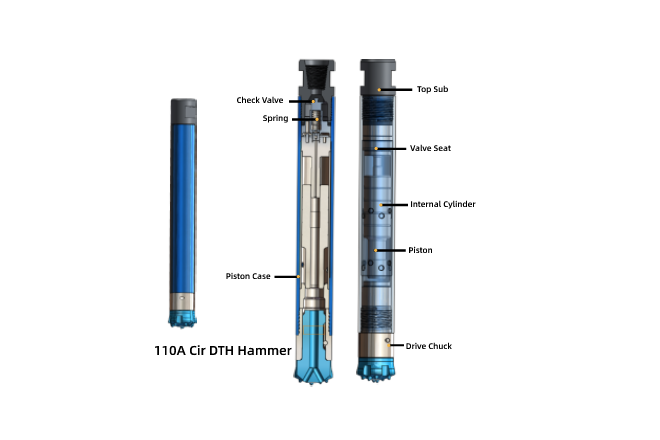

This article focuses on D Miningwell’s DTH (Down-the-Hole) Hammer Parts—specifically the sub components—engineered to enhance the efficiency, reliability, and lifespan of DTH hammers used in mining machinery, water well drilling rigs, and core drilling rigs. It details the key advantages of these parts (high drilling efficiency, low failure rates, long service life), breaks down technical specifications for popular models (CIR50, D56, CIR76A, etc.), and explains how they enable consistent performance even in hard, abrasive rock formations. The piece highlights why these DTH hammer subs are a trusted choice for global procurement teams seeking durable, cost-effective drilling components.

Contact US

Get Price

Share:

Next:

Content

Why D Miningwell DTH Hammer Subs Excel in Tough Drilling Environments

1. High Drilling Efficiency: Maximize Impact & Speed

2. Low Failure Rate: Durable Materials for Reliability

3. Long Service Life: Designed for Extended Use

Technical Specifications: Key D Miningwell DTH Hammer Sub Models

Model Breakdown for Common Applications

Why Global Procurers Choose D Miningwell DTH Hammer Subs

Inquiry

More Low pressure dth hammer