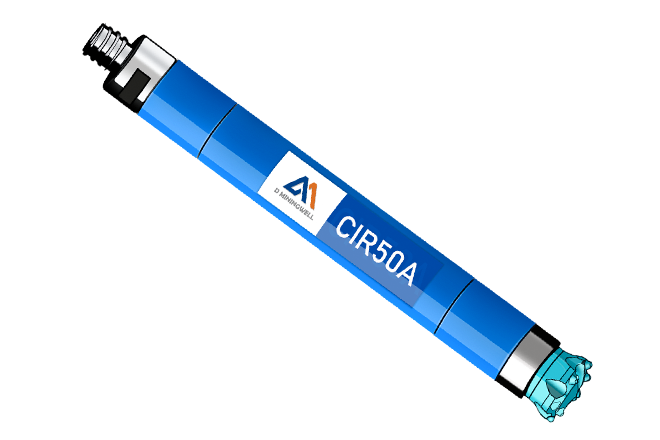

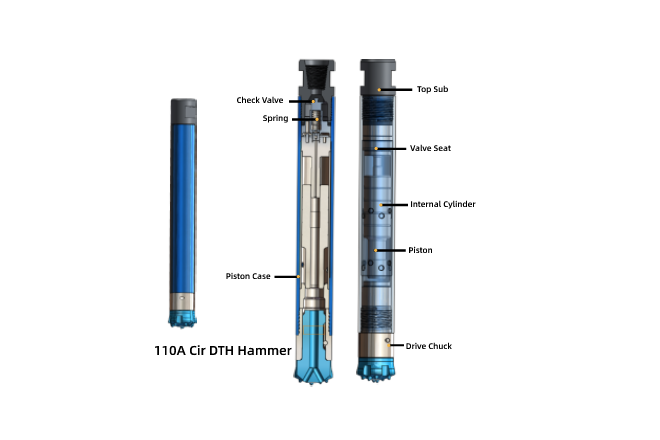

MININGWELL down-the-hole drilling equipment: efficient drilling solutions for hard rock scenarios

In engineering fields such as hydrological well drilling, coreless geological exploration, geological disaster prevention, and mining rock drilling, traditional drilling equipment often faces challenges such as low efficiency and high wear and tear in medium-hard and high-hard rock formations with poor drillability. MININGWELL, a brand specializing in the research and development of drilling equipment, has introduced a down-the-hole drilling system (including down-the-hole impactors and supporting drilling tools). With its targeted structural design and powerful rock-breaking capabilities, it has become a core equipment for conquering complex hard rock formations, providing stable and efficient drilling support for projects in various fields.