D Miningwell DTH Drill Bits: High-Durability Drilling Tools for Water Well & Mining Industries

This article focuses on D Miningwell’s Down-the-Hole (DTH) drill bits—specialized drilling tools engineered for water well drilling, hard rock formation penetration, and mining operations. It details the two core product series (low-pressure CIR series and high-pressure DHD series), their technical specifications, customizable features (tungsten carbide inserts, surface profiles, flush holes), and 30 years of proven export performance. The piece explains how these durable, compatible DTH bits meet the needs of global procurement teams sourcing equipment for water well rigs, mining machinery, and core drilling rigs, highlighting reliability and versatility as key advantages.

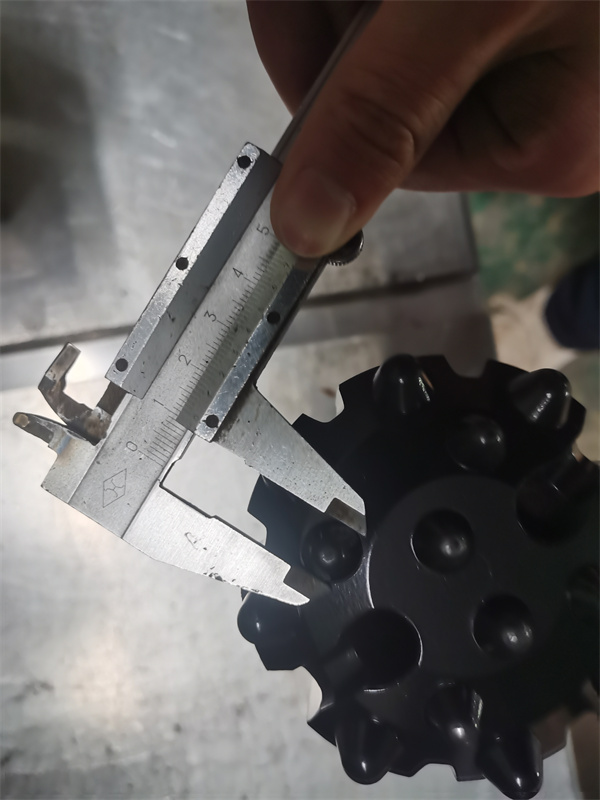

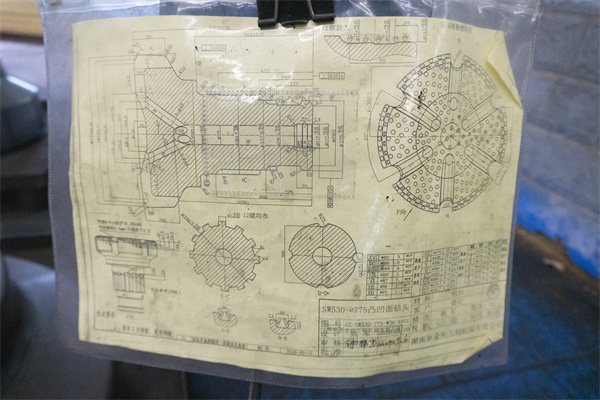

In water well drilling and mining operations, the drill bit is the “frontline” component—its durability, precision, and compatibility directly impact project efficiency, costs, and success. Hard rock formations, variable geological conditions, and high drilling pressures demand tools that can withstand extreme wear while delivering consistent performance. D Miningwell’s DTH (Down-the-Hole) drill bits are designed to meet these challenges: crafted from high-grade carbide inserts and steel, they have served global clients for 30 years, earning trust in water well projects, mining sites, and core drilling operations. For procurement teams sourcing reliable drilling tools for water well rigs, mining machinery, or core drilling rigs, these DTH bits stand out as a long-lasting, cost-effective solution.

CIR series DTH bits(Low pressure)

| Technical Parameters | |||||

| Model: | Gauge buttons(mm) | Front buttons(mm) | Tail shank diameter(mm) | Port holes | Weight(KG) |

| CIR76-76 | φ12*5 | φ12*3 | φ43 | 2 | 2.1 |

| CIR90-90 | φ14*6 | φ13*2+φ12*2 | φ53.5 | 2 | 3.7 |

| CIR90-110 | φ14*6 | φ13*3+φ12*3 | φ53.5 | 3 | 4.6 |

| CIR90-130 | φ14*7 | φ13*3+φ12*4 | φ53.5 | 3 | 6 |

| CIR110-110 | φ14*6 | φ13*3+φ12*3 | φ64 | 3 | 6 |

| CIR110-130 | φ14*7 | φ13*3+φ12*4 | φ64 | 3 | 7.4 |

| CIR110-150 | φ14*8 | φ14*3+φ13*6 | φ64 | 3 | 9.6 |

| CIR110-170 | φ15*9 | φ14*6+φ13*10 | φ64 | 3 | 12.3 |

| CIR110-200 | φ15*9 | φ14*6+φ13*12 | φ64 | 3 | 16.5 |

| CIR150-150 | φ16*9 | φ14*6+φ14*4 | φ89.5 | 3 | 14.8 |

| CIR150-175 | φ16*9 | φ14*6+φ14*5 | φ89.5 | 3 | 19 |

| CIR170-175 | φ16*9 | φ14*6+φ14*5 | φ102 | 3 | 21 |

| CIR170-185 | φ16*9 | φ14*6+φ14*6 | φ102 | 3 | 21.8 |

DHD series DTH bits(High pressure)

| Technical Parameters | |||||||

| Model: | Head diameter: | Shank length: | Spline: | Port holes: | Gauge buttons: | Front buttons: | Weight: |

| DHD25A-76 | 76 | 174 | 6 | 2 | φ14mm*6 | φ11mm*4 | 3.2kg |

| DHD35A-90 | 90 | 180 | 8 | 2 | φ14mm*6 | φ12mm*5 | 4.7kg |

| DHD35A-100 | 100 | 180 | 8 | 2 | φ14mm*6 | φ12mm*5 | 4.8kg |

| DHD340-108 | 108 | 209 | 8 | 2 | φ16mm*7 | φ14mm*6 | 7.85kg |

| DHD340-130 | 130 | 209 | 8 | 2 | φ16mm*8 | φ14mm*4+φ13mm*3 | 8.88kg |

| DHD350-140 | 140 | 260 | 8 | 2 | φ18mm*7 | φ15mm*4+φ14mm*3 | 15.8kg |

| DHD350-152 | 152 | 260 | 8 | 2 | φ18mm*8 | φ14mm*8 | 17kg |

| DHD350-178 | 178 | 260 | 8 | 2 | φ18mm*8 | φ16mm*6+φ14mm*5 | 20.4kg |

| DHD360-154 | 154 | 308.5 | 8 | 2 | φ18mm*8 | φ16mm*4+φ15mm*4 | 22.5kg |

| DHD360-178 | 178 | 308.5 | 8 | 2 | φ18mm*8 | φ16mm*6+φ15mm*5 | 26.1kg |

| DHD360-203 | 203 | 308.5 | 8 | 2 | φ18mm*10 | φ16mm*8+φ15mm*6 | 30.4kg |

| DHD380-203 | 203 | 350 | 10 | 2 | φ18mm*10 | φ18mm*4+φ16mm*10 | 48.5kg |

| DHD380-254 | 254 | 350 | 10 | 2 | φ18mm*12 | φ18mm*12+φ16mm*8 | 62.4kg |