D Miningwell DTH Down-the-Hole Drilling Tools: High-Efficiency Well Drilling Bits for Mining & Drilling Operations

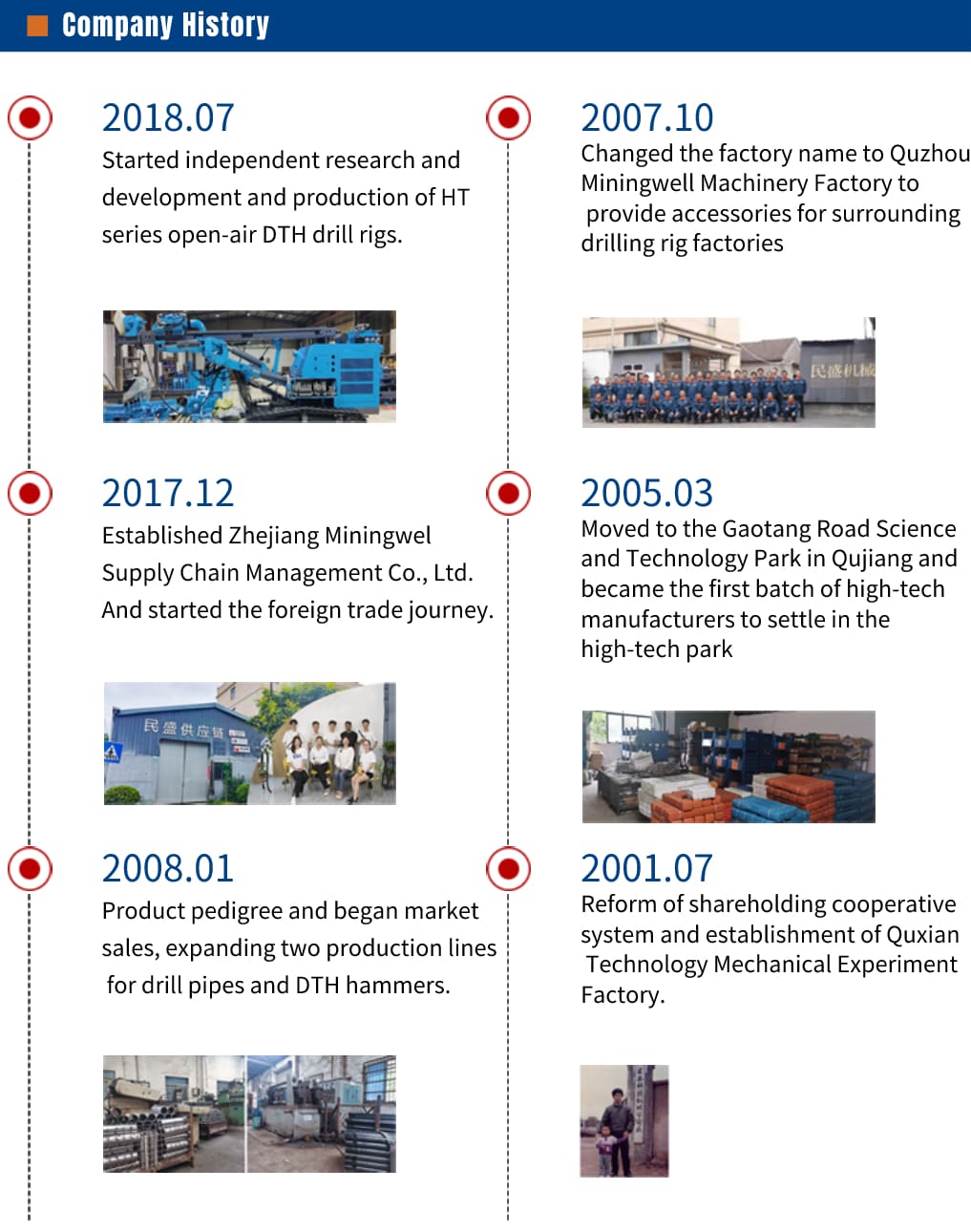

This article focuses on D Miningwell’s DTH (Down-the-Hole) drilling tools—with a core focus on well drilling bits—engineered for durability, speed, and versatility in mining, water well drilling, and core drilling projects. It details the tools’ key advantages (extended lifespan, high drilling efficiency, broad application scope, and cost-effectiveness), breaks down technical specifications for CIR and DHD series bits, and highlights the brand’s 20+ years of manufacturing expertise, OEM support, and 24/7 after-sales service. The piece explains why these DTH tools are a reliable choice for global procurement teams sourcing equipment for mining machinery, water well rigs, and core drilling rigs.

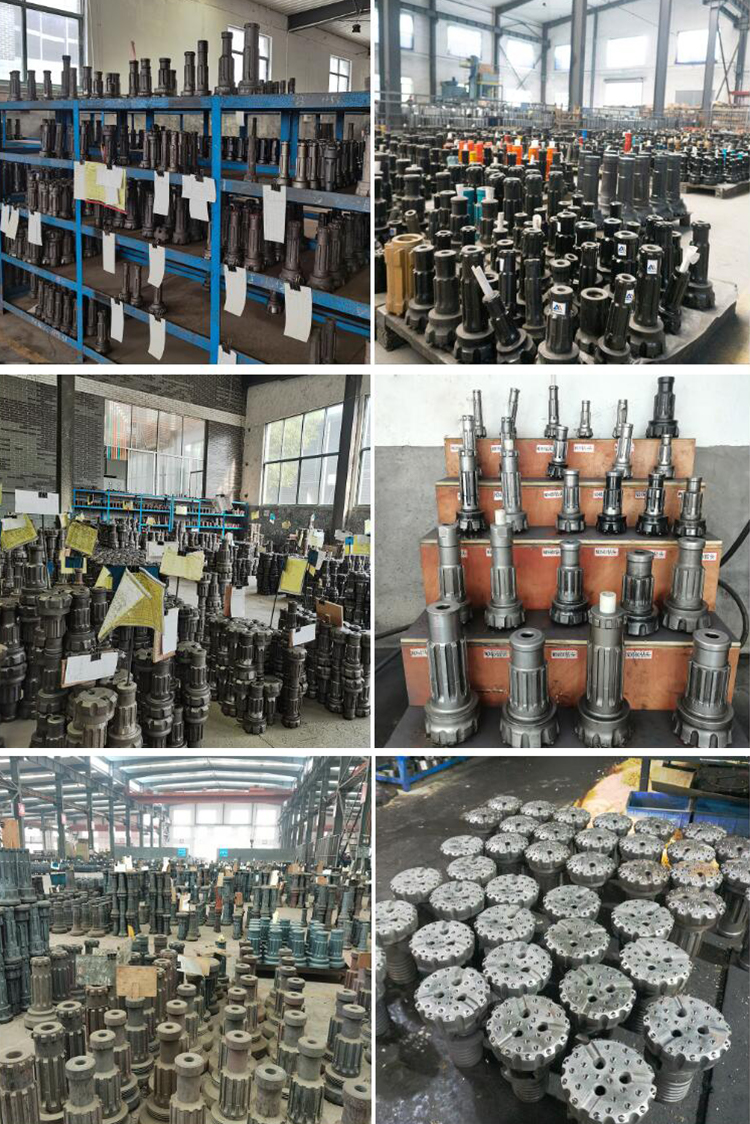

In mining, water well drilling, and core drilling operations, the performance of DTH (Down-the-Hole) drilling tools directly determines project timelines, costs, and success. Hard rock formations, variable geological conditions, and the need for consistent hole quality demand tools that combine durability, speed, and adaptability. D Miningwell—with 20+ years of experience in mining equipment manufacturing—has engineered a line of DTH drilling tools (including well drilling bits) that meet these challenges head-on. Crafted from high-quality steel and alloy steel, using advanced heat treatment and cemented carbide inserting technology, these tools excel in hard rock environments while delivering cost savings for global clients. For procurement teams sourcing reliable components for mining machinery, water well rigs, or core drilling rigs, D Miningwell’s DTH tools stand out as a proven, high-value solution.

Why D Miningwell DTH Drilling Tools Outperform Competitors

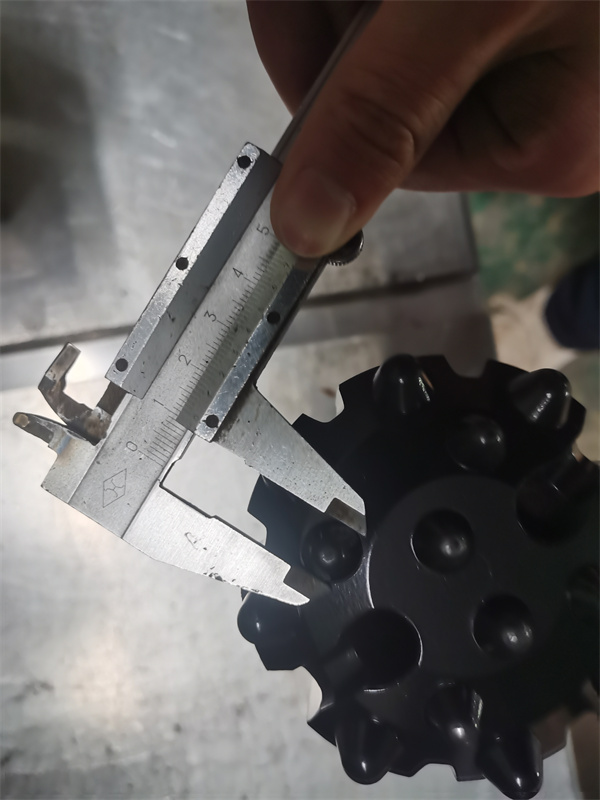

1. Extended Lifespan: Cemented Carbide for Superior Wear Resistance

2. High Drilling Efficiency: Sharp, Consistent Performance

3. Broad Application Scope: Tailored to Diverse Formations

4. Cost-Effectiveness: Lower Total Drilling Costs

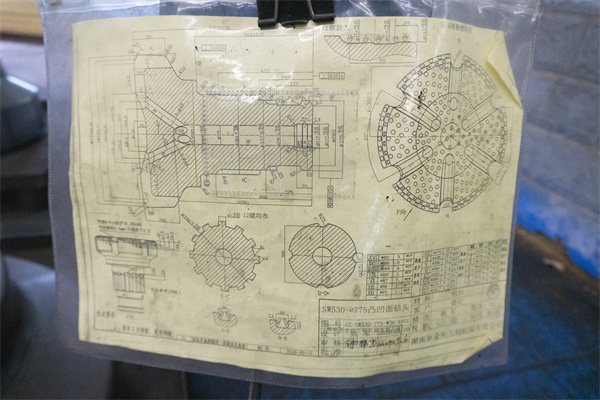

Technical Specifications: CIR & DHD Series DTH Drilling Bits

1. CIR Series: Low-Pressure Performance for Versatile Drilling

2. DHD Series: High-Pressure Power for Hard Rock

Why Global Procurers Trust D Miningwell’s DTH Drilling Tools