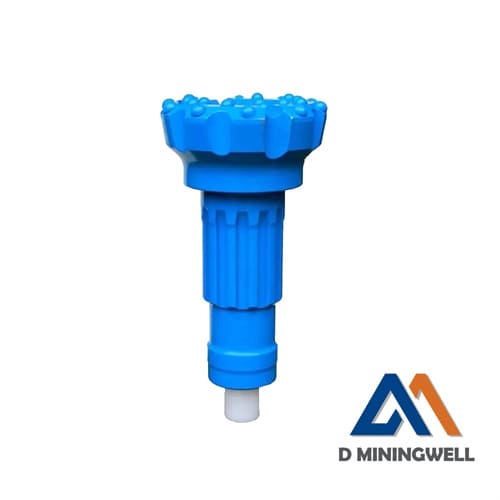

Home » DTH bits » High-Quality Tungsten Carbide DTH Drill Bits from a Leading Chinese Supplier: D Miningwell Empowers Drilling Projects Across Industries

High-Quality Tungsten Carbide DTH Drill Bits from a Leading Chinese Supplier: D Miningwell Empowers Drilling Projects Across Industries

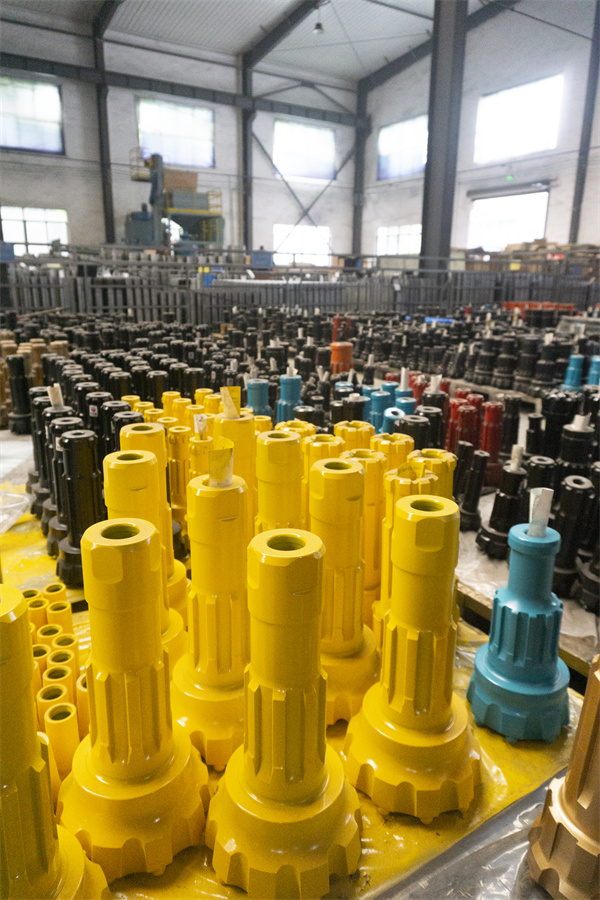

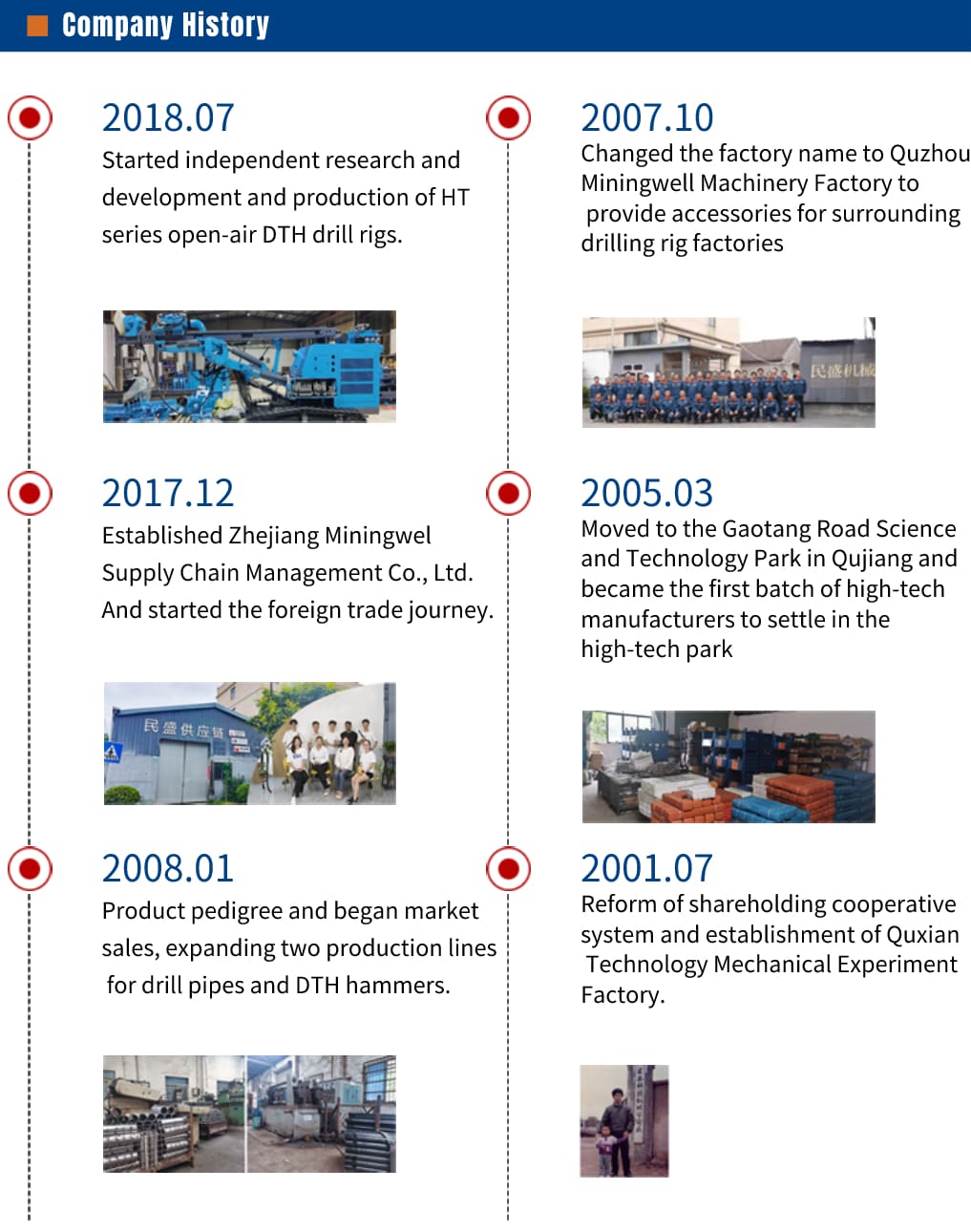

In engineering fields such as mineral exploration, water conservancy construction, and transportation infrastructure, efficient and reliable drilling equipment is crucial for the smooth progress of projects. As a core component, the performance of Down-the-Hole (DTH) drill bits directly determines drilling efficiency and cost control. Hailing from China, Zhejiang Minsheng Supply Chain Management Co., Ltd. (D Miningwell) leverages over 20 years of industry experience and technological innovation to produce tungsten carbide DTH drill bits that stand out for their exceptional quality and adaptability, making them a preferred choice for global drilling projects.

Contact US

Get Price

Share:

Previous:

DTH Hammers Button Bits Suppliers

Next:

Content

| Technical Parameters | |||||||

| Model: | Head diameter: | Shank length: | Spline: | Port holes: | Gauge buttons: | Front buttons: | Weight: |

| DHD25A-76 | 76 | 174 | 6 | 2 | φ14mm*6 | φ11mm*4 | 3.2kg |

| DHD35A-90 | 90 | 180 | 8 | 2 | φ14mm*6 | φ12mm*5 | 4.7kg |

| DHD35A-100 | 100 | 180 | 8 | 2 | φ14mm*6 | φ12mm*5 | 4.8kg |

| DHD340-108 | 108 | 209 | 8 | 2 | φ16mm*7 | φ14mm*6 | 7.85kg |

| DHD340-130 | 130 | 209 | 8 | 2 | φ16mm*8 | φ14mm*4+φ13mm*3 | 8.88kg |

| DHD350-140 | 140 | 260 | 8 | 2 | φ18mm*7 | φ15mm*4+φ14mm*3 | 15.8kg |

| DHD350-152 | 152 | 260 | 8 | 2 | φ18mm*8 | φ14mm*8 | 17kg |

| DHD350-178 | 178 | 260 | 8 | 2 | φ18mm*8 | φ16mm*6+φ14mm*5 | 20.4kg |

| DHD360-154 | 154 | 308.5 | 8 | 2 | φ18mm*8 | φ16mm*4+φ15mm*4 | 22.5kg |

| DHD360-178 | 178 | 308.5 | 8 | 2 | φ18mm*8 | φ16mm*6+φ15mm*5 | 26.1kg |

| DHD360-203 | 203 | 308.5 | 8 | 2 | φ18mm*10 | φ16mm*8+φ15mm*6 | 30.4kg |

| DHD380-203 | 203 | 350 | 10 | 2 | φ18mm*10 | φ18mm*4+φ16mm*10 | 48.5kg |

| DHD380-254 | 254 | 350 | 10 | 2 | φ18mm*12 | φ18mm*12+φ16mm*8 | 62.4kg |

Inquiry

More DTH bits