D Miningwell Design principle of 95scy-10 screw air compressor

Model 95SCY-10

Rated Fashion 10.5 m3 /min | 375 cfm

Rated Pressure 10 bar

Engine Yuchai Diesel 88 kW

Diesel Tank Capacity 180 L

This series is designed for use in down hole drilling, anchor drilling, photovoltaic drilling, rock drilling, water well drilling, etc. with a maximum hole diameter of φ115 mm.

In addition to maintaining reliability, robustness and durability, this series of products has further optimised the control system. As a result, the energy consumption of the products has been greatly reduced.

The whole series of products are equipped with China III or China IV engines and IP55 motors.

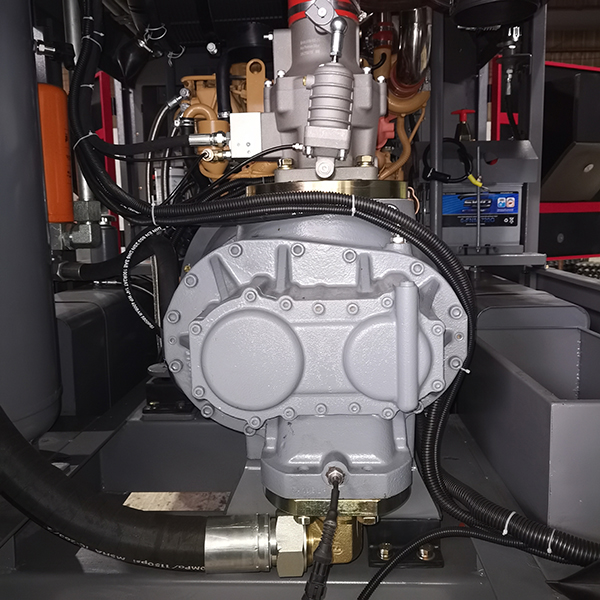

Chigo air compressor 95scy-10 adopts axial piston pump structure design

Its working chamber consists of several pistons and cylinder holes. The plunger makes reciprocating linear movement in the cylinder bore to achieve oil suction and discharge. The cylinder is connected to the drive shaft through splines to transmit power. The flow distribution disc is responsible for controlling the timing of oil suction and discharge. There is a suction window and a discharge window on the distributor. The suction window opens at a specific position to allow the oil to enter. The oil discharge window outputs the high pressure oil at the corresponding stage. The angle of the swash plate determines the size of the plunger stroke.

Changing the swashplate angle adjusts the displacement of the pump. When the swashplate angle increases, the plunger stroke becomes longer. When the angle of the swashplate increases, the plunger stroke becomes longer, and when the angle of the swashplate decreases, the plunger stroke becomes shorter. The rated pressure of the pump can reach a certain value to meet the demand. The specific rated pressure is designed after precise calculation. There are two types of flow adjustment, manual and automatic. Manual adjustment changes the swashplate angle by operating a specific device. Automatic adjustment is based on system pressure and other parameters. The system pressure sensor is used to detect the pressure signal. The detected pressure signal is fed back to the control unit.

The control unit adjusts the swashplate angle according to the signal. The speed range of the pump is strictly defined to guarantee performance. Qualified rotational speed ensures the stable delivery of oil. The pump body is made of high-strength, wear-resistant material. This material can withstand high pressure and friction. The surface of the plunger is specially treated to reduce wear. The internal machining precision of the cylinder body is very high. High-precision machining ensures the fit of the plunger and cylinder body. The sealing performance of the flow distribution point has a great influence on the efficiency, and good sealing can reduce the loss of oil leakage.

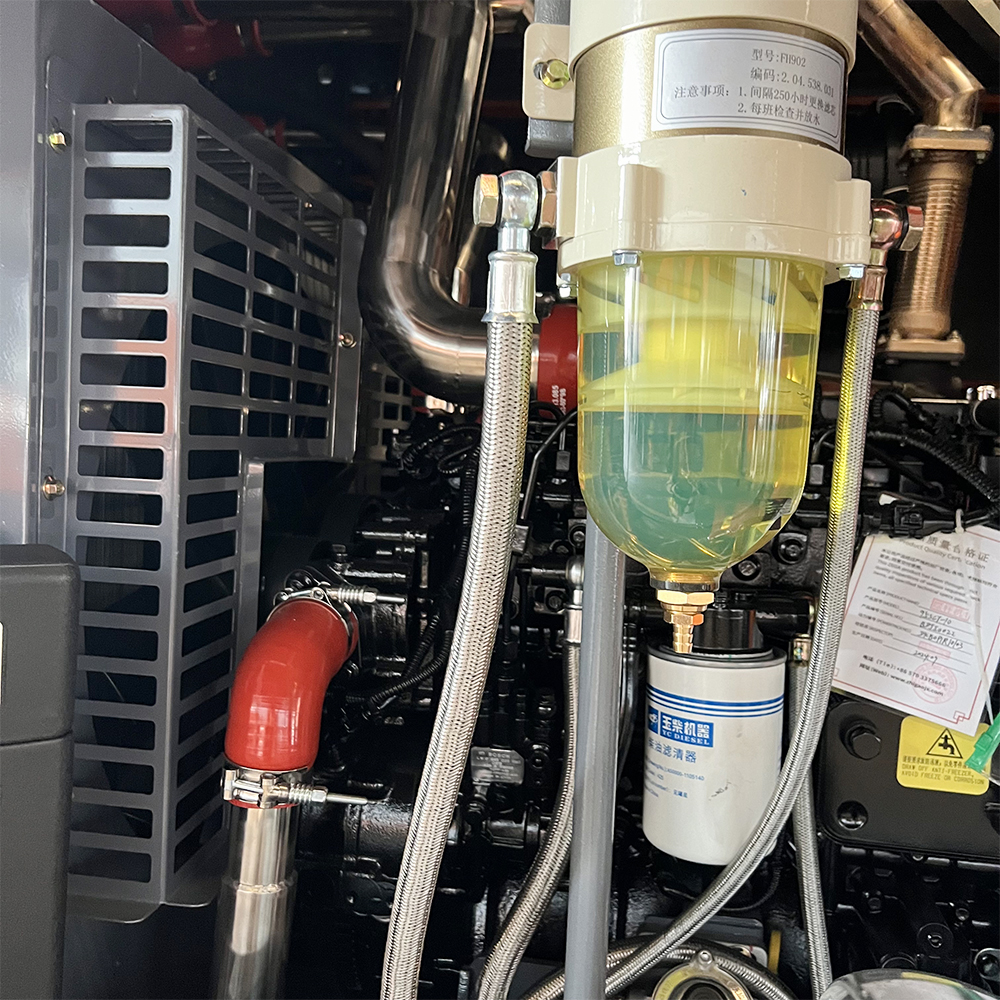

The lubrication system of the pump is essential to ensure the life of the components, the lubricant reaches each friction part through a specific oil circuit. High oil temperatures can affect pump performance and life. An oil temperature detection device is provided to monitor the oil temperature status. A cooling system is used to reduce excessive oil temperatures. Noise control is an important consideration in the design. Optimised structural design reduces noise during operation. Vibration damping materials are used to reduce vibration and noise transmission. The maintenance of the pump has a clearly defined cycle. Regular maintenance can detect and solve potential problems in time. Replacement of wearing parts should be carried out in accordance with the specified requirements.

The wear of the plunger and cylinder bore should be carefully checked during maintenance. If serious wear is found, the corresponding parts should be replaced in time. At the same time, the sealing performance of the flow distribution disc should be tested to ensure that it works properly. The lubricating oil path should also be kept free, to avoid blockage affecting the lubrication effect. For the oil temperature detection device and cooling system, it should be calibrated and cleaned regularly to ensure its accuracy and reliability. In terms of noise control, in addition to the daily attention to the operating noise, it is also necessary to regularly check the state of the damping material, if any aging or damage should be replaced in a timely manner, in order to maintain a good noise reduction effect.

| Model | 95SCY-10 |

| air volume | 10.5 m³/min/375 cfm |

| rated pressure | 10bar |

| motor | Yuchai diesel engine88kW |

| compression stage | 1 |

| Diesel tank capacity | 180 L |

| Maintenance Tank | 30升 |

| Exhaust Oil Content | ≤3 PPM |

| Exhaust Temperature | 80-110℃ |

| Noise level(dB) | ≤85dB |

| Typology | 2 wheels |

| Dimensions (W*H*L) | 3550*2100*2170 mm |

| Weighe | 900Kg |

| discharge | China III/IV |

.jpg)