Atlas Copco’s new diesel-driven mobile air compressor XRVS1100

XRVS1100 is a new product designed by Atlas Copco according to the actual needs of customers with excellent performance, reliability and durability, and low overall cost. The model is paired with Atlas Copco’s high-efficiency screw rotor, powered by a National III emission Cummins engine with a reasonable pressure and air volume ratio, which is especially suitable for drilling applications. It adopts the technologies of energy-saving expert and fuel-saving expert, which can effectively reduce the fuel consumption of the whole machine. The humanised design and solid structure make the equipment strong enough to withstand all kinds of harsh working conditions and easy to maintain. All these are aimed at improving the sustainable productivity of customers.

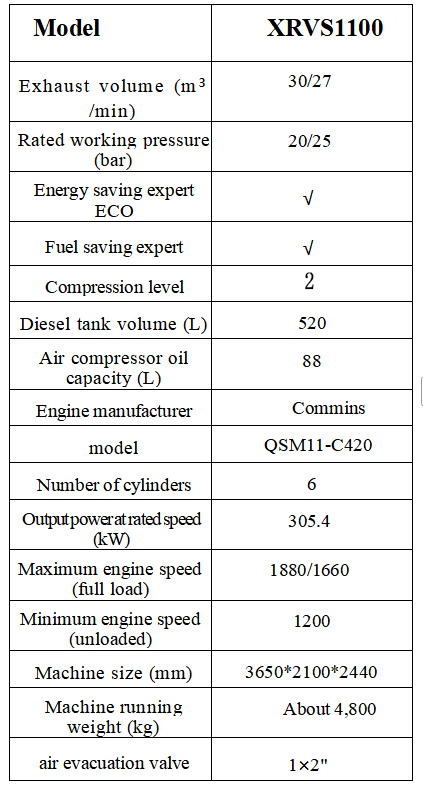

Engine manufacturer: Commins

Exhaust volume (m³/min):30/27

Rated working pressure (bar):20/25

Energy saving expert ECO:√

Fuel saving expert:√

Power System

Engine: Equipped with National III emission Cummins engine, model QSM11-C420, 6-cylinder design, with an output power of 305.4kW at rated speed, it is able to provide strong power support.

Energy and Fuel Saving: Adopting the technology of Energy Saving Expert and Fuel Saving Expert, it can intelligently identify and adjust the operating status of the air compressor, and flexibly switch the working conditions of no-load, unloading and loading to effectively reduce the fuel consumption of the whole machine.

Compression Performance

Displacement: 30/27 m³/min.

Rated Working Pressure: 20/25 bar.

Number of Compression Stages: 2-stage compression with Atlas Copco high-efficiency screw rotor ensures stable pressure and air volume, which can cover a wide range of applications such as water wells and geothermal.

Reliability and durability

Structural design: The whole machine measures 365021002450mm and weighs about 4800kg, with a sturdy structure that can withstand all kinds of harsh working conditions.

Filtration protection: Equipped with double air filters and heavy-duty oil filters to effectively protect the engine and improve the stability of the machine.

Intelligent control

control system: Adopting Atlas Copco’s mature and advanced control system, it monitors the operating conditions of the whole machine in an all-round way and intelligently adjusts the operating status of the equipment, reduces loss and improves working efficiency.

Drilling expert system: optional drilling expert system, intelligent control of pressure and flow, and its dynamic air volume adjustment function can increase the extra air volume by 10%, so that the feed speed can be increased by 30%.

Maintenance: Humanised design makes maintenance more convenient, all maintenance is concentrated on one side, and the fully openable side door is convenient for daily maintenance and repair work.