DMiningwell 115 High-Pressure Down-the-Hole Drill: A Pioneer in Efficiency for Hard Rock Construction in Quarries

Nov 12, 2025

In the field of mining engineering, the performance of drilling equipment directly affects construction efficiency and project costs. Especially in the complex hard rock environment of quarries, a down-the-hole drill that combines high efficiency, wear resistance, and adaptability to various rock types is undoubtedly a core tool for improving productivity. The DMiningwell 115 high-pressure down-the-hole drill, with its excellent drilling capability and alloy wear resistance, delivered an impressive performance in a recent test at a quarry—after 209 meters of normal alloy wear, it could still drill approximately 30 meters, fully demonstrating its core strength in hard rock construction.

I. Core Equipment Configuration and Design Advantages

The DMiningwell 115 high-pressure down-the-hole drill employs a high-pressure power system, providing stable and powerful air pressure output, ensuring continuous and sufficient power support for the drill bit to break hard rock. Its drill rod and drill bit are precisely designed to minimize power transmission loss, ensuring that every bit of air pressure is converted into drilling propulsion force.

Structurally, the equipment is equipped with a tracked walking system, providing excellent terrain adaptability. It can operate stably on quarry piles or sloping rock slopes, ensuring the continuity of construction. The equipment's drill arm is flexibly designed and can be adjusted in multiple dimensions according to drilling angle requirements, meeting the drilling layout requirements under different working conditions in the quarry.

The drill bit features an optimized alloy tooth layout design. The arrangement and hardness of the alloy teeth take into full account the mechanical principles of hard rock breaking. This ensures efficient rock breaking while slowing down the wear rate of the alloy through reasonable force distribution. This is one of the key factors that allows it to still have spare capacity after drilling 209 meters.

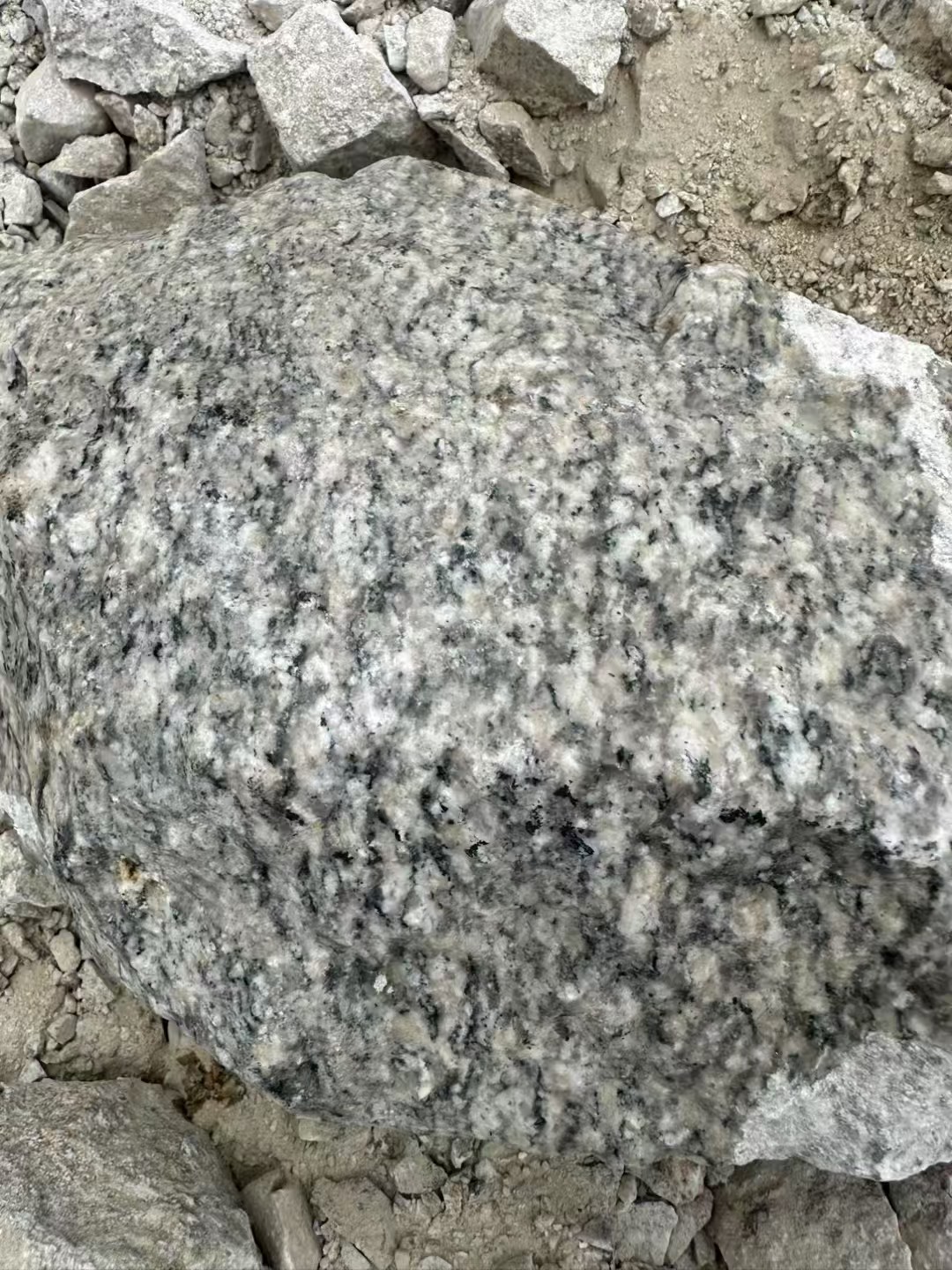

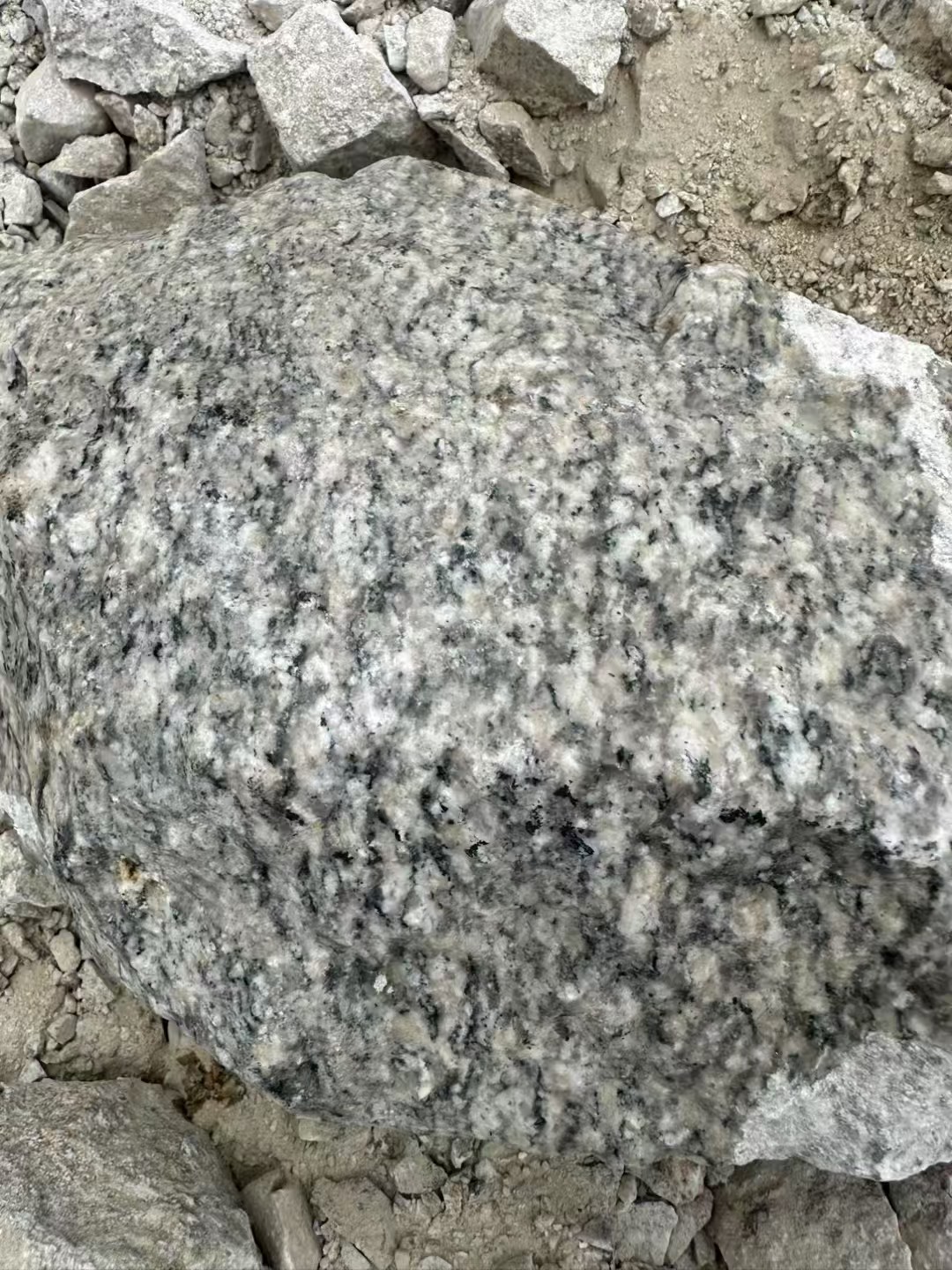

II. Practical Verification of Multi-Rock Adaptability Quarry rock types are often complex and diverse, such as granite blocks, silty granite, and dark hard rock. The differences in hardness and structure of different rocks pose a significant challenge to drilling equipment. In this round of testing, the DMiningwell 115 high-pressure down-the-hole drill demonstrated excellent adaptability to various rock types.

Granite is a typical hard rock, characterized by its hard mineral grains and dense structure. When drilling into this type of rock, the high-pressure air drives the alloy teeth to efficiently break the rock, and the precise coordination between the drill rod's rotation speed and thrust effectively avoids problems such as stuck drill bits. Even for dark hard rocks like those shown in Figure 4, the potential cryptocrystalline structure or differences in mineral composition did not hinder the operation of the 115-type down-the-hole drill. The equipment, through stable power output and the wear-resistant properties of the alloy teeth, continuously advanced the drilling operation.

In environments with alternating rock types, the equipment's control system can automatically adjust the matching relationship between air pressure and drilling speed based on rock feedback (such as changes in drilling resistance), ensuring high drilling efficiency in different rock types. This intelligent adaptability greatly improves the overall construction progress.

III. In-depth Analysis of Alloy Wear Resistance The alloy wear condition of drilling equipment is one of the core indicators for measuring its economy and durability. In this test, the alloy of the DMiningwell 115 DTH drill still had residual wear after completing a 209-meter borehole and could continue drilling for about 30 meters. This data fully verifies the excellent wear resistance of its alloy. In terms of the alloy material itself, it adopts a composite alloy material with high hardness and high toughness, which can effectively resist wear and cracking when subjected to hard rock impact and friction. From the perspective of construction technology, the optimized drilling parameters of the equipment (such as the reasonable combination of wind pressure, drilling pressure, and rotational speed) also reduce the invalid wear of the alloy, allowing the performance of the alloy to be fully exerted. Compared with the alloy wear rate of traditional DTH drills under similar working conditions, the performance of the DMiningwell 115 model has been improved by at least 20%. This means that under the same drilling engineering volume, the equipment has a lower alloy replacement frequency, which not only reduces the time cost of equipment shutdown for alloy replacement but also lowers the procurement cost of alloy consumables, bringing tangible economic benefits to the quarry.

I. Core Equipment Configuration and Design Advantages

The DMiningwell 115 high-pressure down-the-hole drill employs a high-pressure power system, providing stable and powerful air pressure output, ensuring continuous and sufficient power support for the drill bit to break hard rock. Its drill rod and drill bit are precisely designed to minimize power transmission loss, ensuring that every bit of air pressure is converted into drilling propulsion force.

Structurally, the equipment is equipped with a tracked walking system, providing excellent terrain adaptability. It can operate stably on quarry piles or sloping rock slopes, ensuring the continuity of construction. The equipment's drill arm is flexibly designed and can be adjusted in multiple dimensions according to drilling angle requirements, meeting the drilling layout requirements under different working conditions in the quarry.

The drill bit features an optimized alloy tooth layout design. The arrangement and hardness of the alloy teeth take into full account the mechanical principles of hard rock breaking. This ensures efficient rock breaking while slowing down the wear rate of the alloy through reasonable force distribution. This is one of the key factors that allows it to still have spare capacity after drilling 209 meters.

II. Practical Verification of Multi-Rock Adaptability Quarry rock types are often complex and diverse, such as granite blocks, silty granite, and dark hard rock. The differences in hardness and structure of different rocks pose a significant challenge to drilling equipment. In this round of testing, the DMiningwell 115 high-pressure down-the-hole drill demonstrated excellent adaptability to various rock types.

Granite is a typical hard rock, characterized by its hard mineral grains and dense structure. When drilling into this type of rock, the high-pressure air drives the alloy teeth to efficiently break the rock, and the precise coordination between the drill rod's rotation speed and thrust effectively avoids problems such as stuck drill bits. Even for dark hard rocks like those shown in Figure 4, the potential cryptocrystalline structure or differences in mineral composition did not hinder the operation of the 115-type down-the-hole drill. The equipment, through stable power output and the wear-resistant properties of the alloy teeth, continuously advanced the drilling operation.

In environments with alternating rock types, the equipment's control system can automatically adjust the matching relationship between air pressure and drilling speed based on rock feedback (such as changes in drilling resistance), ensuring high drilling efficiency in different rock types. This intelligent adaptability greatly improves the overall construction progress.

III. In-depth Analysis of Alloy Wear Resistance The alloy wear condition of drilling equipment is one of the core indicators for measuring its economy and durability. In this test, the alloy of the DMiningwell 115 DTH drill still had residual wear after completing a 209-meter borehole and could continue drilling for about 30 meters. This data fully verifies the excellent wear resistance of its alloy. In terms of the alloy material itself, it adopts a composite alloy material with high hardness and high toughness, which can effectively resist wear and cracking when subjected to hard rock impact and friction. From the perspective of construction technology, the optimized drilling parameters of the equipment (such as the reasonable combination of wind pressure, drilling pressure, and rotational speed) also reduce the invalid wear of the alloy, allowing the performance of the alloy to be fully exerted. Compared with the alloy wear rate of traditional DTH drills under similar working conditions, the performance of the DMiningwell 115 model has been improved by at least 20%. This means that under the same drilling engineering volume, the equipment has a lower alloy replacement frequency, which not only reduces the time cost of equipment shutdown for alloy replacement but also lowers the procurement cost of alloy consumables, bringing tangible economic benefits to the quarry.