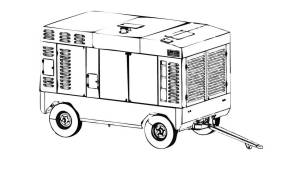

Professional Water Well Drilling Solutions for Canada — Introducing the MWT350 Truck-Mounted Drilling Rig

As an experienced producer and exporter of drilling rigs for trucks, we embrace the concepts of “Quality First, Customer Oriented, and Professional Service.” We aim to provide first-rate, reliable, and versatile drilling apparatus and service solutions to international customers, especially for technically challenging markets like Canada. We had a detailed technical discussion with a Canadian buyer for our MWT350 model lately. We discussed every question thoroughly, and we are honored to deliver this detailed introduction to the MWT350, featuring its characteristics, performance, fuel economy, and professional support before, during, and after the sale.

1. Core Advantages of the MWT350 Drilling Rig

The MWT350 is a multifunctional water well drilling rig capable of operating under various drilling methods:

-

Direct mud circulation

-

Down-the-hole (DTH) hammer drilling

-

Mud DTH drilling

-

Airlift reverse circulation

-

Rotary drilling

-

Rotary mud drilling

These flexible drilling modes enable the rig to adapt to diverse geological formations, making it highly effective across Canada’s varied terrain.

Key capabilities include:

-

Max drilling depth: up to 350 meters

-

Hole diameter: 105mm to 450mm

-

Drilling speed: 15–35 meters/hour depending on strata

-

Lifting force: 20,000 kg

-

Adjustable chuck: accommodates pipes up to 450mm in diameter for rapid tool changes

These characteristics make the MWT350 particularly suitable for water wells, geothermal wells, agricultural irrigation wells, and so on.

2. Power System & Technical Specifications

The MWT350 features a 142 kW (190 HP) high-torque EPA-approved engine, which is environmentally and emission-compliant according to Canadian standards. It features a Canadian-specification fuel tank to promote safety and reliability during extended operations.

-

Average fuel consumption: 20–25 liters/hour under normal conditions (depending on load, drilling depth, and method)

-

BW600 hydraulic mud pump: designed for high flow and head pressure, ideal for both mud and mud-DTH drilling

-

28 MPa hydraulic foam pump: adjustable flow rate (up to 20 L/min), ensures proper lubrication and cooling in air drilling

-

Battery system: guarantees stable performance of electronic and control modules in low temperatures or high-altitude sites

3. Structural Design & Operational Efficiency

The rig is equipped with four hydraulic leveling legs, allowing fast and precise setup on uneven terrain.

-

Quick-adjust chuck: suits pipes up to 450mm, facilitating rapid pipe changes and minimizing downtime

-

Hydraulic rod loader and automatic high-speed rod support: accommodates 60 rods (Ø89mm), drastically reducing manual handling and enabling continuous drilling

-

Modular design: simplifies transport, site setup, and commissioning, significantly cutting down on preparation time

4. Full-Cycle Professional Service: Before, During, and After Sales

We go beyond equipment delivery — we provide a complete service ecosystem to ensure your drilling success.

Pre-sale services:

-

Detailed technical documentation and strata adaptability analysis

-

Equipment configuration customized to your project needs

-

Online live demonstrations and operational walkthroughs

Mid-sale services:

-

Real-time production progress updates

-

Remote inspection options to ensure product quality prior to shipment

-

Support with logistics, customs clearance, and certifications

After-sales support:

-

Technical manuals, maintenance guides, troubleshooting documentation

-

Remote or on-site training and commissioning by experienced engineers

-

24/7 multilingual technical support

-

Long-term supply of genuine spare parts

5. Fuel Consumption Insights & Optimization Tips

Fuel economy is a major concern, especially in remote or high-volume drilling projects. The MWT350 is engineered for efficiency.

Under typical working conditions (e.g., drilling to 200 meters in medium-hard strata using mud circulation), the engine consumes about 22 liters/hour. For deeper or harder formations (e.g., >300 meters or hard rock), consumption may rise to 25–27 liters/hour.

Fuel-saving recommendations:

-

Use DTH instead of full mud drilling when possible

-

Optimize drilling RPMs and feed rates

-

Perform regular engine and hydraulic system maintenance

-

Choose the most efficient drilling method for the strata

6. Field-Proven Success and Market Readiness

The MWT350 has been successfully deployed in the Middle East, Central Asia, South America, and Africa and so on. It has proven its reliability in extreme conditions such as high heat, humidity, cold climates, High altitude areas .

For the Canadian market, we offer customized cold-weather configurations, including cold-start systems, low-temperature hydraulic fluids, and thermal insulation for key components.

Our engineering team has extensive international experience and has supported major water resource projects worldwide. We are well-done in working across cultures and complying with regional standards.

Conclusion

The MWT350 is not just a drilling rig — it shows our pursuit of excellence in performance, efficiency, and customer service. Whether you located in Eastern Canada or the western provinces,we have the expertise and equipment to meet your needs.

We warmly welcome your inquiries and are ready to work with you. Let’s work together to your next drilling project .

.png)

.png)