High Wind Pressure Down Hole Hammer – Down Hole Hammer Bit Manufacturer

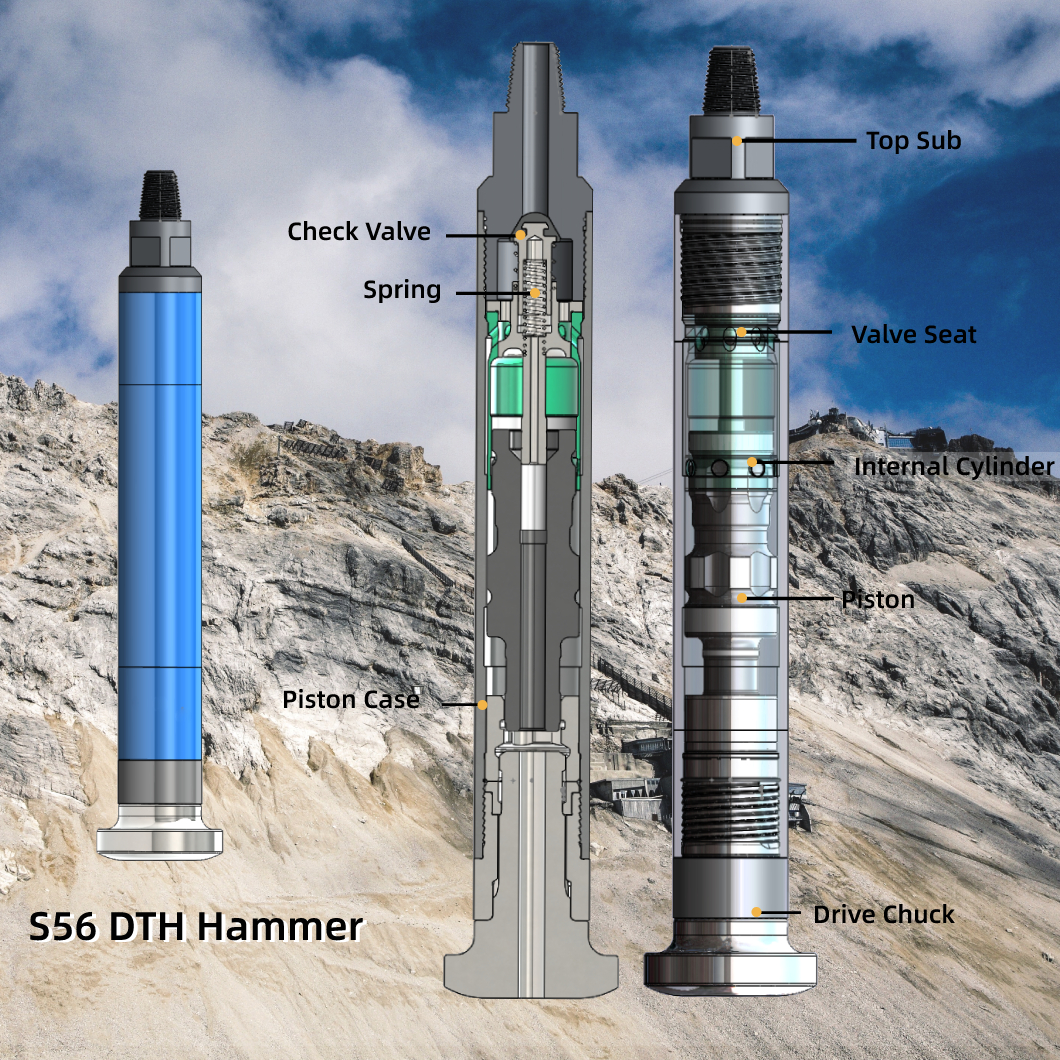

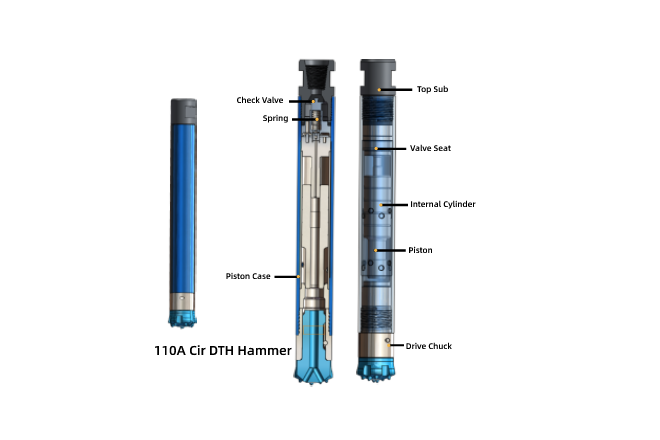

D Miningwell drilling hammers are designed with advanced drilling theory, which makes our drilling hammers have good energy transfer performance, faster drilling speed and lower air consumption. High quality raw materials, advanced processing technology, stable performance and long service life. Easy to use, easy to install and dismantle, easy to repair and easy to maintain.S56 DTH (Down-The-Hole) Hammer Impactor is composed of top joint, valve seat, inner cylinder, piston, drive chuck, piston sleeve, check valve, spring.

Improve drilling efficiency

High-efficiency rock crushing: the impactor uses compressed air or liquid medium to generate continuous impact load, and through the reciprocating motion of the piston and cylinder, the impact energy is transferred to the drill bit, crushing the rock by impact, significantly improving the drilling speed, especially in hard, crushed rock formations the effect is particularly significant.

Reduce auxiliary time: the down-the-hole impactor takes the air as the medium, and there is no need to recycle and dispose of rinsing medium, further increasing the drilling efficiency. Ensure drilling quality Stable drilling: the variable diameter design of the impactor reduces debris and soil jamming during drilling, reducing failures. It reduces the auxiliary operation time and further improves the drilling efficiency.

Ensure the quality of drilling

Stable drilling: The variable diameter design of the impactor can reduce the phenomenon of gravel and mud jamming when drilling, reduce the probability of failure, and ensure the stability of the drilling process.

Maintaining the integrity of the hole wall: When drilling by submerged impactor, the hole wall is more intact without pollution by other media, and it can keep the original It can maintain the original formation structure and water permeability, which is conducive to subsequent operations.

Adaptation to complex environments

Wide range of applications: the impactor is suitable for hydrological and water well drilling, geological drilling, rock drilling in mines and other fields, and it can be used in pebble and gravel, hard rock formations and soft soil formations.

Handling of special formations: in the formations of serious leakage and unstable borehole wall, the subsea percussor can be used to follow the pipe drilling, which can solve the problems of complex formations.

Reducing the cost and saving energy: the subsea percussor is used to follow the pipe drilling to reduce faults, and to ensure the stability of the drilling process. Cost saving

Energy saving: Submersible impactor requires small axial pressure, low rotational speed and low torque on the drilling rig, which consumes little power and saves energy cost.

Extending drilling tool life: impactor drilling efficiency is high, and drilling tool life is long, which reduces the frequency of replacing the drilling tool, and lowers the construction cost.

| Model | S36 | S46 | S56 |

| Length(Lessbit) | 745 mm | 837 mm | 811 mm |

| Weight (Lessbit) | 35.36kg | 34.55kg | 68.6kg |

| External diameter | 82 mm | 102 mm | 126 mm |

| Hole Range | φ90-100 mm | φ110-150 mm | φ150-250 mm |

| Connection Thread | API2 3/8″REG | API2 3/8″REG | API2 3/8″REG |

| WorkingPressure | 1.2-1.8MPa | 1.2-1.8MPa | 1.2-1.8MPa |

| Parts | Weight (kg) | ||

| Check valve | 0.12 | 0.25 | 0.38 |

| Big spring | 0.004 | 0.02 | 0.056 |

| Valve seat | 0.83 | 1.3 | 2.18 |

| Cylinder | 0.89 | 1.67 | 2.11 |

| Piston | 4.72 | 7.82 | 11.91 |

| Guide sleeve | 0.89 | 1.7 | 3.18 |

| Rear connector | 3.64 | 6.82 | 11.11 |

| Outer casing | 8.3 | 11.63 | 20.58 |

| Front connector | 1.73 | 2.97 | 5.63 |