Home » Drilling Rod » Friction welding drill rod(DTH) » MININGWELL 89mm×3000mm API Double-Buckle Friction Welded Drill Pipe: A High-Quality Choice for Water Well Drilling

MININGWELL 89mm×3000mm API Double-Buckle Friction Welded Drill Pipe: A High-Quality Choice for Water Well Drilling

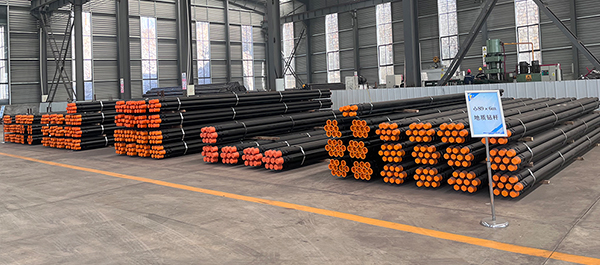

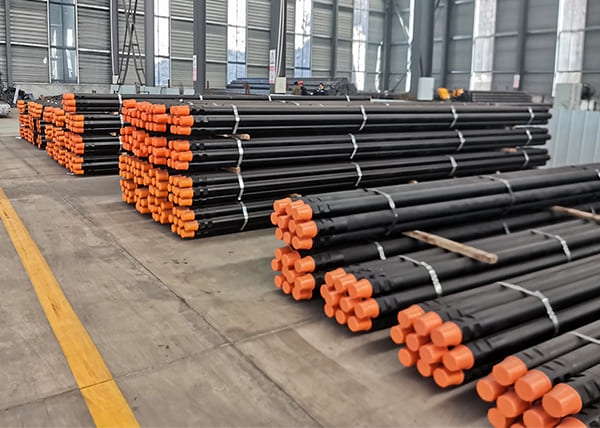

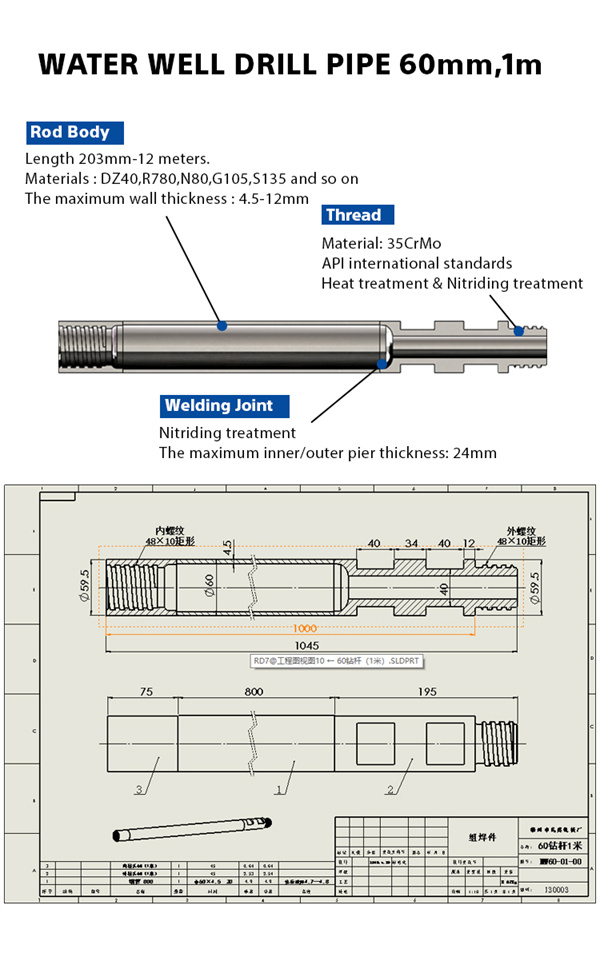

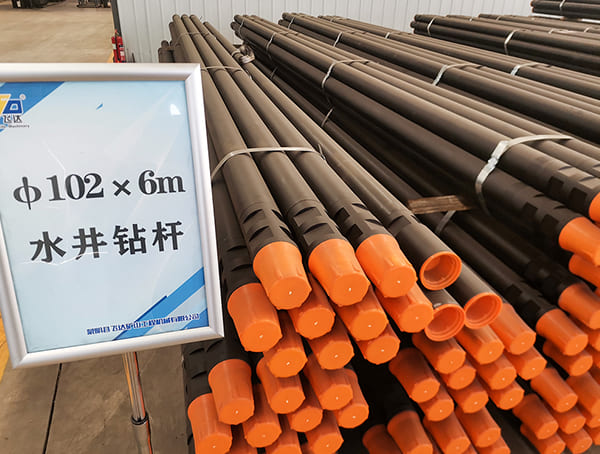

In engineering fields like water well drilling and geological exploration, drill pipe, the core component connecting the drilling rig and the drill bit, is crucial for drilling efficiency and operational safety. MININGWELL’s 89mm x 3000mm API double-buckle friction-welded drill pipe, leveraging advanced friction welding technology, strict material control, and precision design that meets international standards, has become the preferred equipment for water well drilling. Currently on sale for a limited time at a factory direct price, it provides engineering teams with a cost-effective solution.

Contact US

Get Price

Share:

Content

Inquiry

More Friction welding drill rod(DTH)