D Miningwell Used Diesel Air Compressor LUY160-17: Cost-Effective Power for Mining & Drilling Operations

This article focuses on the D Miningwell Used Diesel Air Compressor LUY160-17, a high-value second-hand solution designed to meet the compressed air needs of mining machinery, water well drilling rigs, and core drilling rigs. It details the compressor’s key specifications (including 160cfm air volume and 17bar pressure), rigorous pre-sale inspection process, compatibility with diverse drilling equipment, and cost-saving advantages. The piece also explains why this used diesel compressor is a reliable choice for global procurement teams seeking budget-friendly yet high-performance air compression solutions for harsh mining and drilling environments.

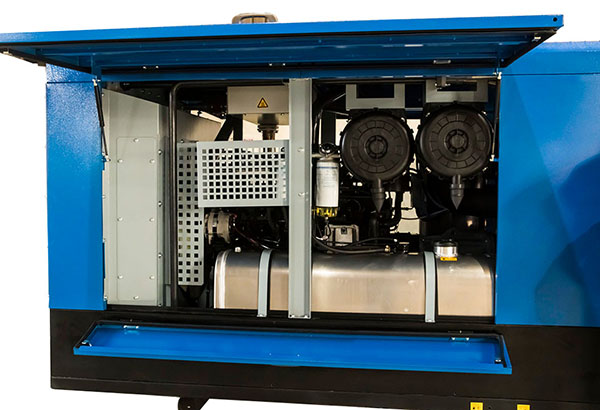

In the mining, water well drilling, and core drilling industries, compressed air is the lifeblood of operations—powering everything from rock breakers on mining machinery to the drilling mechanisms of water well rigs. Yet, investing in brand-new air compressors can strain budgets, especially for small-to-medium operations or short-term projects. The D Miningwell Used Diesel Air Compressor LUY160-17 solves this challenge: it delivers the power and durability required for harsh job sites while offering significant cost savings compared to new equipment. For global procurement teams sourcing reliable, budget-friendly solutions for mining and drilling, this second-hand diesel compressor stands out as a smart investment.

| Technical Parameters | |

|

Model

|

LUY160-17

|

|

Work pressure (bar)

|

17

|

|

Volume flow (m³/min)

|

16

|

|

Type

|

Screw

|

|

Configuration

|

Portable

|

|

Noise decibel

(7 meters away)

|

83±3

|

|

Fuel tank capacity(L)

|

250

|

|

Compressor oil capacity(L)

|

32

|

|

Outlet valve inch-Quantity * size

|

1*G2 1*G3/4

|

|

Dimension(mm)

|

4322*1950*2010

|

|

Weight(kg)

|

2550kg

|

|

Engine technical parameters

|

|

|

Brand

|

Yucai

|

|

model

|

YC6A240-H301

|

|

Power Source

|

Diesel

|

|

engine (Kw)

|

176

|

|

MAX. Engine speed (rpm)

|

1950

|

|

Unloading engine speed(rpm)

|

1200

|