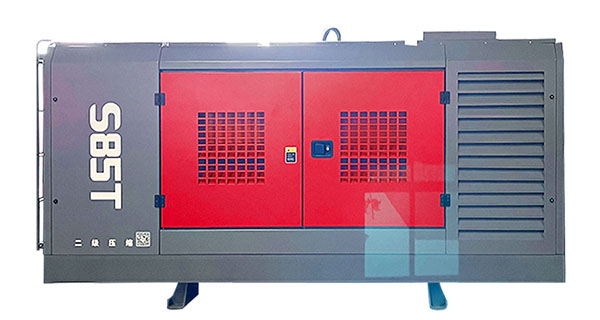

D miningwell truck mounted rotary screw air compressor 18 m3/min 18 bar 162 kW diesel compressor

This product is designed for water well drilling rigs with a diameter of φ115-262mm and related compressed air stations required for water well, geothermal and other projects. Under the premise of adhering to the characteristics of mobile air compressors, this product is designed for continuous use and transportation size requirements of the product. Multiple upgrades and optimizations, more products and lower fuel consumption.

Installation site requirements for screw air compressors

The selection of the installation site is very important for the use of the air compressor system. The installation site of the screw air compressor should be convenient for the maintenance of the air compressor in the future, and at the same time, the influence of environmental factors on the operation of the air compressor should be avoided.

First of all, the installation site must ensure good lighting, and sufficient lighting is required for daily operation and maintenance. In addition, the surrounding environment should have low humidity, no corrosive gas, or an environment with large dust is not suitable, and at the same time ensure good ventilation conditions.

Second, if the surrounding environment is poor, a ventilation pipe needs to be installed to lead the air inlet end to a place with relatively clean air. In addition, pay attention to the convenience of disassembly and assembly when installing the conduit, which is convenient for future maintenance. The specific installation size should refer to the external size of the air compressor.

Third, when installing the air compressor, pay attention to leaving enough space around, the distance from the wall to the wall should be more than 1.5 meters, and the distance from the top space should be more than 10 meters to ensure that the parts can be easily entered and exited.

Fourth, when the screw air compressor is installed in a closed space, an exhaust fan needs to be installed, so that the gas after heat exchange can be discharged outdoors in time. When the ambient temperature is too high, special cooling measures should be taken to prevent the normal operation of the air compressor from being affected by the high temperature.

Fifth, the use of air compressors should also pay attention to energy conservation and environmental protection. The sewage and waste oil generated by the compressor should be properly treated and discharged in accordance with the regulations of relevant environmental protection departments to avoid environmental pollution.

To sum up, the use of screw air compressors should select a suitable installation site according to the requirements, and also follow relevant regulations during the transportation and installation process to avoid unnecessary damage.

| Model | Air Capacity (m3/min) | Air Pressure (bar) | Engine (kW) | Air End | Weight (kg) | Type |

| S60 | 18 | 18 | 162 | Single Stage Compression | 3,000 | Fixed SKID |

| S85D | 24 | 22 | 228 | Two Stage Compression | 3,560 | Fixed SKID |

| S95CD | 29 | 24 | 295 | Two Stage Compression | 4,700 | Fixed SKID |

| S98D | 30 | 24 | 295 | Two Stage Compression | 4,620 | Fixed SKID |

| S100D | 31 | 25 | 309 | Two Stage Compression | 4,600 | Fixed SKID |

| S125D | 36 | 30 | 410 | Two Stage Compression | 5,280 | Fixed SKID |