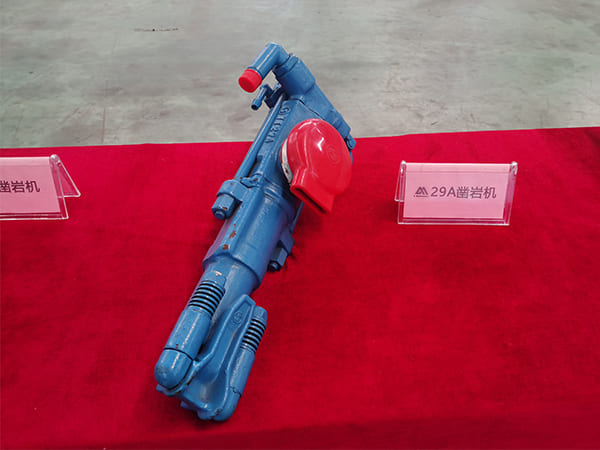

D miningwell heavy duty jack hammer prices used jack hammer Y018

The air-leg rock drill is installed on the air leg for operation, and the air leg can play the role of support and propulsion, which reduces the labor intensity of the operator, and the rock drilling efficiency is higher than the former. The drilling depth is 2-5m and the diameter is 34- 42mm horizontal or with a certain inclination of the blasthole, which is widely used in mines. Such as YT23, YT24, YT28, YTP28 and other models are such rock drills.

Analysis on the use of rock drills

1. The machine has anti-rust oil when it leaves the factory. It should be disassembled and cleaned before use. When reassembling, the mating surface should be lubricated with lubricating oil, and the trolley should be run for trial operation.

2. When connecting the gas and water pipes, the debris in the pipes must be blown to avoid entering the machine and affecting the normal operation of the machine; when drilling, keep the water pressure 0.1-0.15MPA lower than the air pressure. So as not to let the flushing water enter the inside of the body, affect the lubrication, and bring in the sundries.

3. Before ventilation and water, carefully check whether the connection parts are safe and reliable to avoid loosening and hurting people.

4. Fill the oiler with oil before starting the machine, and it is strictly forbidden to operate without lubrication.

5. When using on-site with super gas, lubricating oil with low flash point and easy to ignite cannot be used, and the machine is not allowed to run idly to prevent explosion accidents.

6. Adjust the oil valve, it is advisable to add oil once an hour.

7. When working, pay special attention to the sudden breakage of the drill rod; pay attention to prevent being pinched between the rock drill and the air leg.

8. When the machine is finished, the water source should be turned off first, and then run for a while to remove the accumulated water in the machine and prevent rust.

9. The machine that is used continuously should be maintained regularly, the stolen goods in the machine should be removed, the damaged parts should be replaced, and the hidden troubles should be removed.

10. If the used machine is stored for a long time, it must be disassembled and washed, oiled, and placed in a cool and dry place.

11. Air legs and oiler are controlled by the safety standard. Users should choose the above-mentioned parts (components) of our company to match with the host.

12. When the pneumatic rock drill is working, noise, vibration and dust will be generated, please pay attention to the protection of the operator, and need to wear muffler earmuffs, etc.

15. If the oiler housing has cracks, please replace it in time.

| Pneumatic Rock Drill With Air Leg | |||||

| Technical Parameters | YT28 | YT27 | YT29A | YT24C | TY24 |

| Weight(kg) | 26 | 27 | 26.5 | 24 | 24 |

| Length(mm) | 661 | 668 | 659 | 628 | 678 |

| Air Pressure(Mpa) | 0.4-0.63 | 0.4-0.63 | 0.4-0.63 | 0.4-0.63 | 0.4-0.63 |

| Impact Rate(Hz) | ≧37 | ≧39 | ≧39 | ≧37 | ≧31 |

| Air consumption(L/S) | ≦81 | ≦86 | ≦88 | ≦80 | ≦67 |

| Impact Energy(J) | ≧70J | ≧75J | ≧78J | ≧65J | ≧65J |

| Cylinder*Stroke(mm) | 80*60 | 80*60 | 82*60 | 76*60 | 70*70 |

| Air Pipe Diameter(mm) | 25 | 19 | 25 | 25 | 19 |

| Shank Dimension(mm) | 22*108 | 22*108 | 22*108 | 22*108 | 22*108 |

| Drilling Depth(m) | 5 | 5 | 5 | 5 | 5 |

| Bit Diameter(mm) | 34-42 | 34-45 | 34-45 | 34-42 | 34-42 |