Atlas Copco Mobile Screw Air Compressors X-AIR+ 600-17

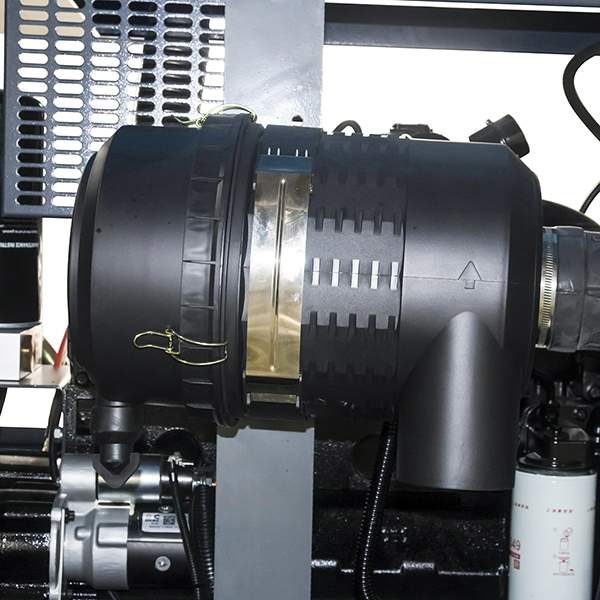

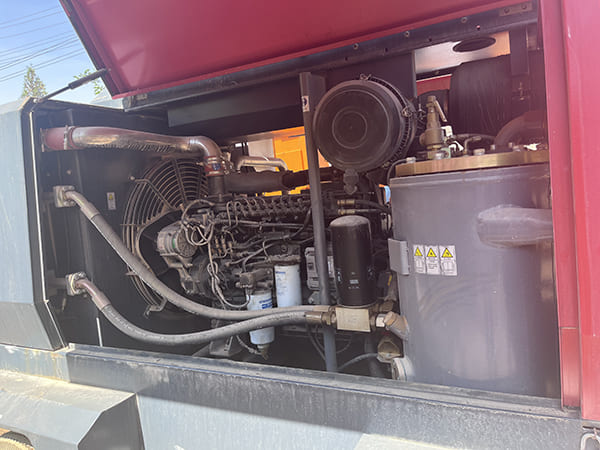

Atlas Copco mobile screw air compressor X-AIR+ 600-17 is powered by Cummins National IV diesel engine.

The air compressor operates at 78 dB noise control, adapting to noise-sensitive operating environments; the Atlas Copco air compressor with the lowest life cycle cost. Atlas Copco air compressors are energy-efficient and have a small footprint, making them suitable for complex scenarios such as mine blasting and construction sites. Towable design for flexibility and ease of operation. Reduced long-term operating costs through fuel economy and low maintenance requirements.

Atlas Copco’s mobile screw air compressor X-AIR+ 600-17 is a medium-sized mobile compressor designed for high efficiency, environmental protection and complex working conditions.

I. High efficiency, energy saving and intelligent control

1.PACE pressure regulation expert system

supports dynamic air volume adjustment, accurately matches air demand through electronic control, reduces ineffective energy consumption, saves fuel by more than 5%, and improves drilling efficiency by 5-10%.

has a wide range of pressure adjustment (5-17 bar), realising multi-purpose use and covering a variety of application scenarios.

2.Dynamic air volume adjustment technology

automatically adjusts the exhaust volume (17.5-15.0 m³/min) according to the load, avoiding energy waste and reducing operating costs.

Second, environmental protection and low emission

1.National IV emission standard

diesel-driven version complies with GIV (National IV) emission standards, reducing NOx emissions by 13%-45% and particulate emissions by 50%-94%.

2.Low noise design

running noise is controlled at 78 dB, adapting to the noise-sensitive operating environment.

Extreme environmental adaptability

1. Rugged and durable structural design

adopts high-performance chassis and chassis cover, which is resistant to high temperature, high cold, high altitude and other harsh working conditions, and adapts to mine blasting, construction sites and other complex scenes.

2.Long life and low maintenance

core components (such as screw rotor, gears) by the European design test, long maintenance cycle, low failure rate.

High-performance parameters and application adaptation

1. High power and large exhaust volume

has a rated power of 154 kW and an exhaust volume of 17.5-15.0 m³/min, which meets the demand for high loads (e.g. mine blasting and drilling).

2.Modularity and manoeuvrability

The towable design of supports quick transfer, adapts to trailer or fixed installation, and is highly flexible.

Economy and Sustainability

1.Lower Total Cost of Ownership (TCO)

reduces long-term operating costs through fuel economy and low maintenance requirements.

2.Green Energy Compatibility

supports integration with energy storage systems (e.g. ZenergiZe series) and future expansion to new energy supply modes.

Main technical parameters

Air compressor form: one-stage screw compression, air cooling, diesel engine drive, field mobile operation

| technical parameter | X-AIR+ 600-17 | |

| Rated gas volume FAD | Cubic meter/meter m³/min | 17.2-14.3 |

| working pressure | kilogram bar | 5-17 |

| Maximum engine speed (full load) | Turns per minute rpm | 2200-1900 |

| Screw lubricating oil volume | rise L | 42 (replacement per maintenance cycle) |

| Gas storage tank (oil and gas separation tank) volume | rise L | 76 |

| Fuel tank/carbon canister volume | rise L | 175/- |

| Oil content in compressed air outlet | ppm | <5 |

| Compressed air outlet temperature (based on rated reference condition) | In degrees Celsius, 0C | 100 |

| Rated reference condition | ||

| Absolute intake pressure | kilogram bar | 1 |

| relative air humidity | % | 0 |

| Import air temperature | In degrees Celsius, 0C | 20 |

| Extreme working conditions | ||

| Minimum effective working pressure of gas tank | kilogram bar | 4 |

| Maximum effective working pressure of the gas tank (unloading) | kilogram bar | 18 |

| Maximum ambient temperature | In degrees Celsius, 0C | 50 |

| Minimum starting temperature | In degrees Celsius, 0C | -10/-25 (optional cold start) |

| Highest altitude | rice m | 3000 |

Diesel engine

| manufacturer | Commins | |

| model | B5.9CS4 GIV Standards | |

| Output power at rated speed | kilowatt kW | 154 |

| load factor | % | – |

| coolant | coolant liquid | |

| Number of cylinders | In-line 6 cylinder | |

| Lubricating oil system volume | rise L | 16.5 (Replacement per maintenance cycle) |

| Cooling system volume | rise L | 28 |

Overall size and weight

| Overall length * width * height-towing type (including mop) | millimetre mm | 4700*1940*2400 |

| Overall length * width * height-box type | millimetre mm | 2960*1400*2110 |

| Overall weight of trailer/cabinet (wet weight) | kilogram kg | 2300/2200 |

| Exhaust valve size | cun in | 1*G2,1*G3/4 |