I. Core Advantages: Premium Materials and Craftsmanship Forge Outstanding Performance

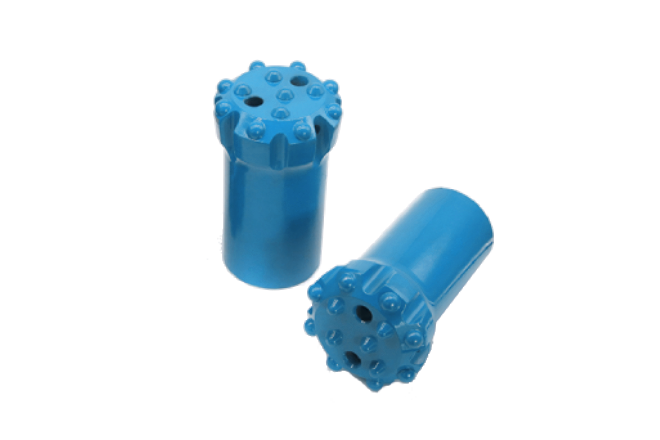

The exceptional performance of MININGWELL's conventional top-hammer threaded button bits stems from the strict control over core materials and production craftsmanship. High-quality alloy steel plates and tungsten carbide are adopted as raw materials — the alloy steel plates possess excellent toughness and fatigue resistance, enabling them to withstand high-frequency impacts and wear during rock drilling; the buttons made of tungsten carbide feature extremely high hardness, which can effectively crush hard rocks, reduce drilling resistance, and extend the service life of the bits.

Through professional heat treatment technology, the overall mechanical properties of the bits are further optimized: on one hand, the enhanced toughness allows them to adapt to complex rock stratum environments and avoid breakage caused by impacts; on the other hand, the improved surface hardness reduces energy loss during drilling. Practical application data shows that when drilling in hard rock (with a firmness coefficient f = 8~18), the energy loss rate of these bits is more than 15% lower than that of ordinary similar products, significantly increasing the duration of a single operation and drilling efficiency.

Meanwhile, the bits are manufactured using hot pressing or welding processes to ensure a firm connection between the buttons and the bit body, preventing button detachment during high-intensity drilling. Each of the two processes has its own advantages: the hot pressing process enables a tighter combination between the buttons and the bit body, making it suitable for ultra-hard rock drilling; the welding process boasts high production efficiency and can meet large-batch conventional demands. Selection can be made flexibly according to different engineering scenarios.

II. Abundant Specifications: Precisely Adapting to Diverse Drilling Needs

To meet the full-range drilling requirements from soft rock to hard rock, MININGWELL offers a wide range of specifications for its conventional top-hammer threaded button bits. The core parameters and applicable scenarios are as follows. These bits can be accurately matched with rock drill rods of various specifications such as R22, R25, R28, R32, R35, R38, T38, T45, T51, ST58, and GT60, ensuring stable power transmission and avoiding drilling deviations.

1. Parameters and Application Scenarios of Main Models

| Model Series |

Bit Head Shape |

Bit Head Diameter (mm) |

Length (mm) |

End Hole/Side Hole Configuration |

Guide Button Specification |

Application Scenarios |

| R25 |

Flat Face |

38-45 |

105-110 |

1 end hole + 2 side holes, 3 end holes + 2 side holes |

5Φ8, 6Φ9 |

Shallow hole drilling in soft rock for small mines, such as pre-splitting drilling in coal seams of coal mines and small-scale municipal blasting operations |

| R32 |

Flat Face, Convex Face |

45-76 |

113-130 |

3 end holes + 2 side holes, 2 end holes (no side holes) |

6Φ9, 6Φ10, 6*Φ12 |

Small and medium-sized infrastructure projects, such as drilling in loose medium rock for highway subgrades and shallow hole construction for building foundations |

| R38 |

Center Drop Face |

64-89 |

130 |

3 end holes (no side holes), 2 end holes + 2 side holes |

6Φ11, 8Φ12 |

Drilling in medium-hard rock (f=12~15), such as middle-layer mining in metal mines and auxiliary blasting hole drilling in tunnels |

| T38 |

Center Drop Face, Flat Face |

64-89 |

130 |

2 end holes (no side holes), 3 end holes + 2 side holes, 4 end holes (no side holes) |

8Φ9, 6Φ12, 8Φ11, 8Φ12 |

Medium-sized mine mining and infrastructure blasting, such as mining holes in iron mines and reinforcement drilling for railway subgrades |

| T45 |

Center Drop Face, Triangle Face, Flat Triangle Face |

72-115 |

140-160 |

4 end holes (no side holes), 3 end holes (no side holes) |

8Φ11, 8Φ12, 8Φ13, 9Φ13, 9*Φ14 |

Drilling in medium-hard to hard rock (f=14~17), such as blasting for granite subgrades and drilling for large hydropower station dams |

| T51 |

Center Drop Face, Flat Face, Flat Triangle Face |

89-127 |

155-165 |

4 end holes (no side holes), 2 end holes + 2 side holes, 3 end holes (no side holes) |

8Φ12, 8Φ14, 9Φ13, 9Φ14 |

Deep drilling in hard rock, such as deep mining in metal mines and main blasting hole drilling in tunnels |

| ST58 |

Center Drop Face, Flat Face |

89-127 |

175-185 |

4 end holes (no side holes), 3 end holes (no side holes), 2 end holes + 2 side holes |

8Φ12, 9Φ13, 8*Φ14 |

Drilling in high-strength hard rock (f=16~18), such as tunnel excavation in basalt and deep mining in large mines |

| GT60 |

Flat Triangle Face |

102-140 |

220-230 |

3 end holes (no side holes) |

9Φ13, 9Φ14, 9*Φ16 |

Large-diameter drilling in ultra-hard rock, such as diversion holes in large water conservancy projects and ultra-deep mining holes in metal mines |

| ST68 |

Flat Face, Center Drop Face |

102-140 |

180-190 |

2 end holes + 2 side holes, 4 end holes (no side holes) |

8Φ14, 8Φ16 |

Extra-large infrastructure and mine projects, such as deep foundation drilling for cross-sea bridges and blasting holes in large open-pit mines |

2. Functional Advantages of Bit Head Design

Different bit head shapes are optimized for specific drilling needs to ensure drilling efficiency and stability:

- Flat Face: It has a large contact area and strong drilling stability, suitable for vertical drilling in uniform rock formations, such as blasting holes for building foundations and shallow hole construction for highway subgrades.

- Convex Face: Stress is concentrated in the central area, suitable for crushing heterogeneous soft rock and reducing cuttings accumulation, such as drilling in loose sandstone.

- Center Drop Face: The concave design in the center allows for quick discharge of cuttings, avoiding blockages in the hole, and is suitable for high-viscosity rock formations, such as drilling in shale and mudstone.

- Triangle Face and Flat Triangle Face: They have good stress concentration, high efficiency in crushing hard rock, and excellent drilling perpendicularity. They are suitable for drilling in hard rocks such as granite and basalt, such as deep mining in metal mines and main blasting hole drilling in tunnels.

In addition, some models (e.g., R25-38mm, T38-70mm, T51-115mm) are equipped with side holes, which enhance the cuttings discharge capacity, prevent overheating and wear of the bits caused by cuttings accumulation, and are especially suitable for drilling in high-viscosity rock formations or deep holes.

III. Customization Services: Solving Personalized Drilling Challenges

In addition to conventional specifications, MININGWELL also provides customized bit services. Key parameters can be adjusted according to customers' specific drilling scenarios to meet the needs of special working conditions:

- Button Shape Customization: Two types of buttons are available — spherical and ballistic. Spherical buttons have uniform wear and are suitable for long-term stable drilling; ballistic buttons have sharper tips and stronger crushing force, making them suitable for ultra-hard rock (f>18) or high-intensity drilling needs.

- Bit Head Shape and Hole Position Optimization: Based on rock hardness, drilling depth, and application purposes, the curvature of the bit head, the number of end holes, and the position of side holes can be adjusted. For example, for inclined rock formations, an offset end face can be customized to reduce drilling deviation; for deep hole drilling, the number of side holes can be increased to improve cuttings discharge efficiency.

- Dimension Personalization: Customization of non-standard bit head diameters and lengths is supported. For instance, bits with a diameter of more than 150mm can be customized for large water conservancy projects to meet the needs of diversion holes and anti-seepage wall drilling; short-length bits (<100mm) can be customized for small tunnel construction to adapt to narrow operating spaces.

IV. Procurement and Support: Professional Services Throughout the Entire Process

To ensure customers' procurement experience and subsequent usage support, MININGWELL has established a sound supply chain and service system:

- Low-Threshold Procurement: The minimum order quantity is only 1 set, supporting small-batch trial orders, which reduces the procurement cost for small and medium-sized engineering teams while meeting the bulk procurement needs of large-scale projects.

- Safe Packaging and Fast Delivery: Standard export packaging is adopted, which is waterproof, moisture-proof, shock-resistant, and pressure-resistant to avoid damage to the bits during transportation. The delivery cycle for conventional specification products is 7-10 days, and urgent orders can be processed with expedited production to shorten the delivery time and ensure project progress.

- Flexible Payment Methods: Various payment methods such as L/C (Letter of Credit), T/T (Telegraphic Transfer), and Western Union are supported, adapting to the trade settlement needs of different regions around the world and reducing the risks of cross-border procurement.

- Authoritative Quality Certification: The products have obtained dual international certifications of CE and ISO. Their materials, craftsmanship, and safety performance comply with global industrial standards, making them reliable for use in various high-demand engineering scenarios.

V. Wide Applications: Empowering Efficiency Improvement in Multiple Engineering Fields

With excellent performance and flexible adaptability, MININGWELL's conventional top-hammer threaded button bits have been widely used in various engineering fields around the world, becoming a "rock drilling tool" for engineering teams:

- Mineral Mining Field: In mines such as gold mines, iron mines, coal mines, and non-ferrous metal mines, they are used for drilling mining holes, blasting holes, and exploration holes. They are suitable for ore bodies of different hardness, improving mining efficiency and ore recovery rate.

- Infrastructure Engineering Field: They are used for blasting drilling of highway and railway subgrades, reinforcement drilling of bridges and high-rise building foundations, as well as foundation treatment of airport runways and port terminals, ensuring the quality and construction safety of infrastructure projects.

- Tunnel and Underground Engineering Field: They are applied to excavation drilling and advanced geological exploration drilling in railway tunnels, highway tunnels, and urban subway tunnels, as well as guide hole drilling in the construction of underground pipe corridors and comprehensive pipe corridors, coping with complex underground rock stratum environments.

- Water Conservancy and Hydropower Field: They are used for reinforcement drilling of reservoir dams, drilling of water diversion tunnels in hydropower stations, drilling for water transmission pipeline laying, and drilling of anti-seepage walls in flood control projects, meeting the high requirements of water conservancy projects for precision and durability.

- Municipal Engineering Field: They are employed in subgrade treatment drilling during urban road renovation, detection hole drilling during underground pipeline maintenance, and drilling for anti-seepage layer construction in garbage landfills, contributing to the upgrading of urban infrastructure.

Whether for conventional projects or special working conditions, MININGWELL's conventional top-hammer threaded button bits can provide engineering teams with stable performance, abundant specifications, and customized services to reduce construction costs and improve operation efficiency, serving as an important equipment support for promoting the high-quality development of global engineering construction.

(1).jpg)

.jpg)

(1).jpg)

(1).jpg)

.jpg)

(2).jpg)

(1).jpg)